|

Transmission, Remove and Install (Z13DTH/M20

MTA)

Note: If the

transmission is replaced, the following parts must be

transferred:

| 1. |

Bracket, left engine damping block |

| 2. |

MTA system |

| 3. |

Transmission closure cap with gasket. The closure

cap gasket must be transferred on the old transmission. When

attaching the MTA system to the exchange transmission, a new gasket

must be used. |

Remove Remove

Important: Before carrying out

any work on the M20-MTA transmission, it is essential that the MTA

system pressure (approx. 40-60 bar) is released.

|

| 1. |

Remove MTA system pressure

|

| 2. |

Remove battery support

|

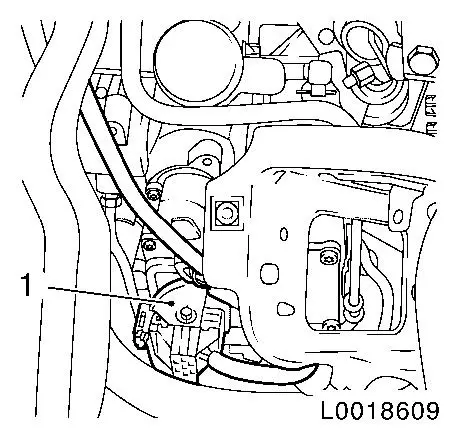

| 4. |

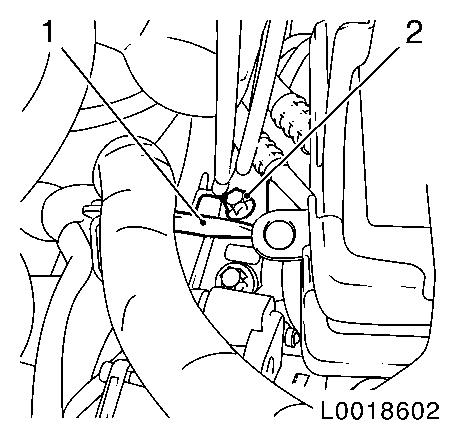

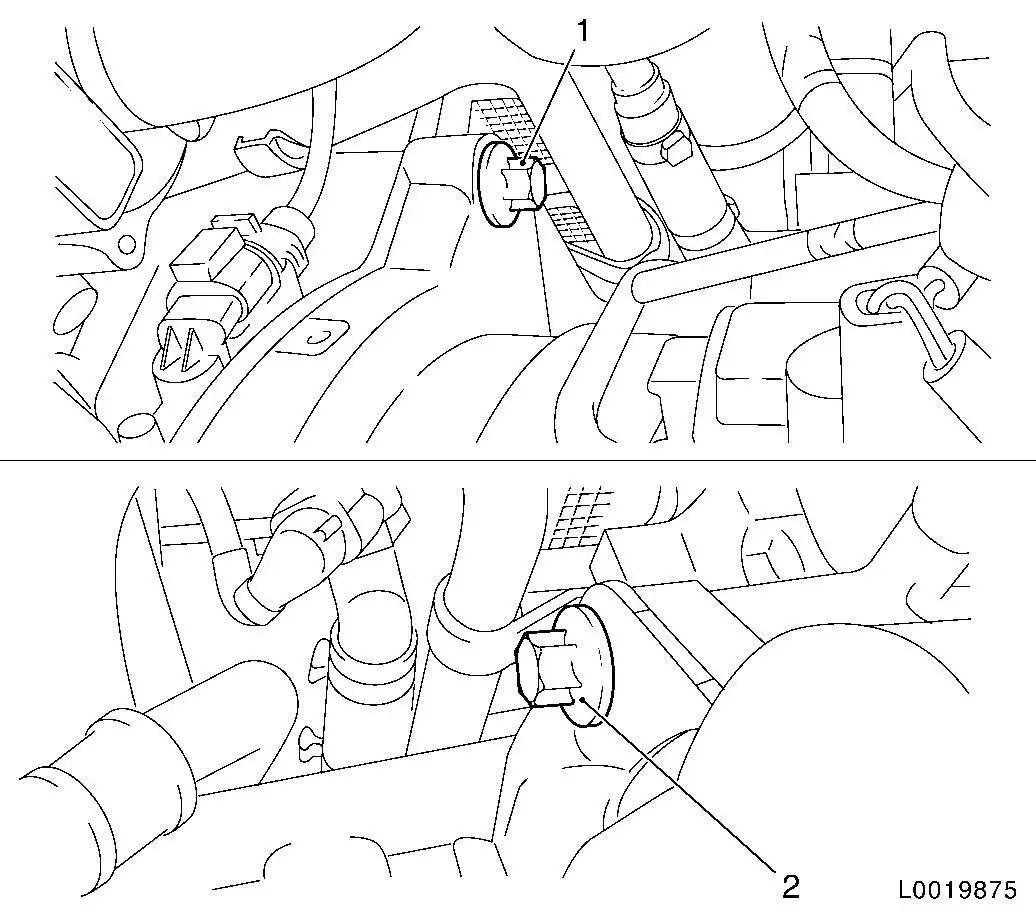

Detach battery wiring harness bracket (1) from MTA supply

unit

|

|

|

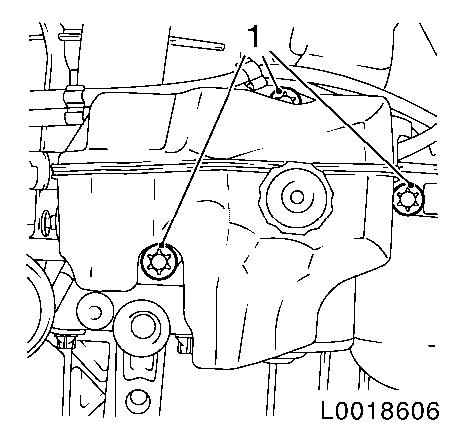

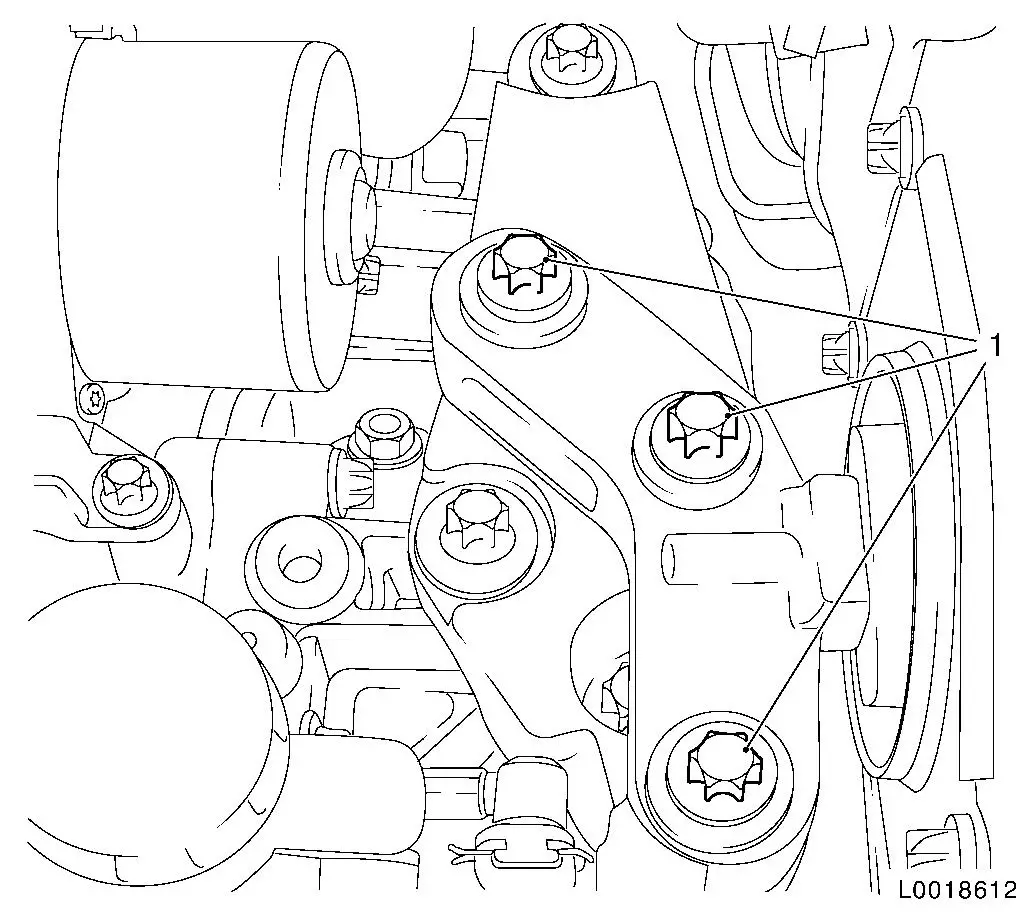

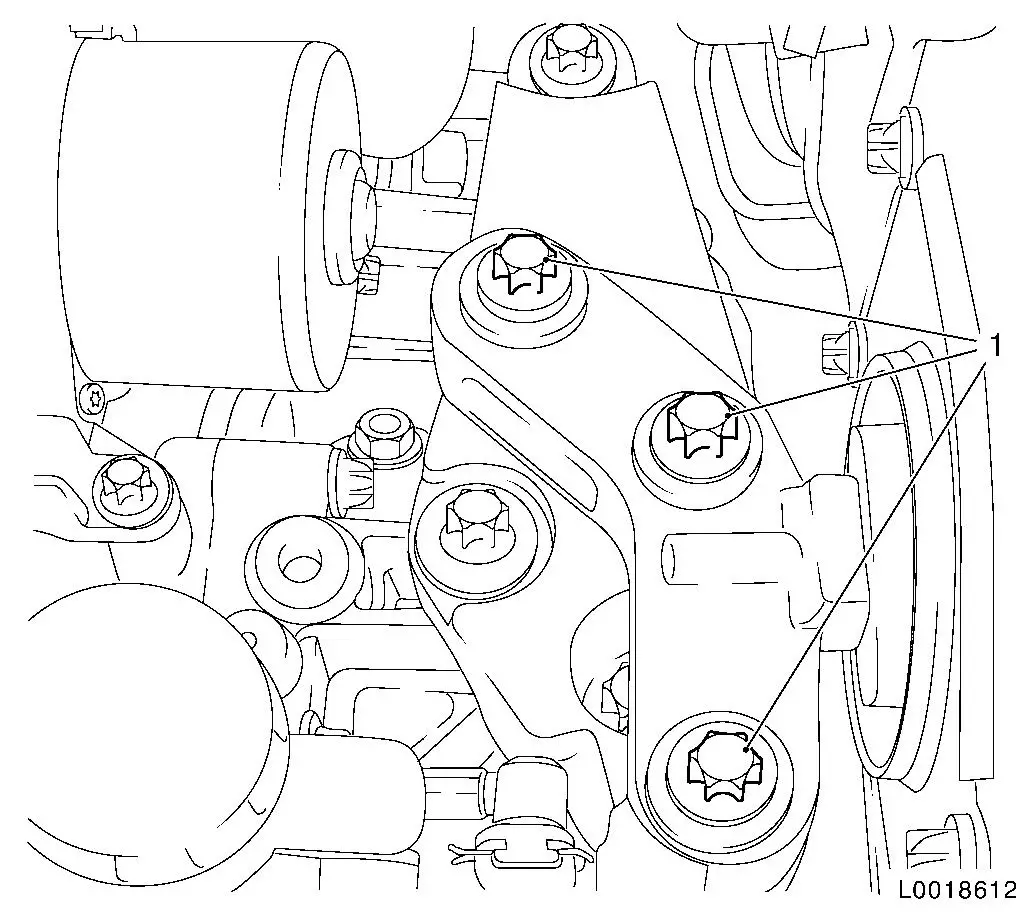

| 5. |

Release MTA system supply unit

| • |

Unscrew 3x bolt (1)

Note: Note differing

bolt lengths

|

|

|

|

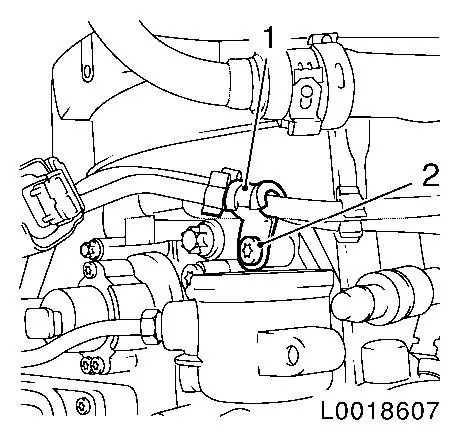

| 6. |

Release MTA wiring harness bracket (1)

|

|

|

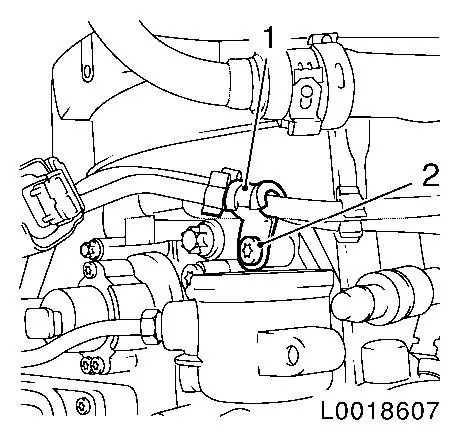

| 7. |

Disconnect MTA system wiring harness

| • |

Release wiring harness plug (1) and disconnect

|

|

|

|

| 8. |

Drain off transmission fluid

Note: Place collecting

pan underneath.

| • |

Unscrew drain plug

Note: Allow

transmission fluid to drain out for approx. 10 minutes.

|

| • |

Tighten new drain plug 20 Nm

|

|

|

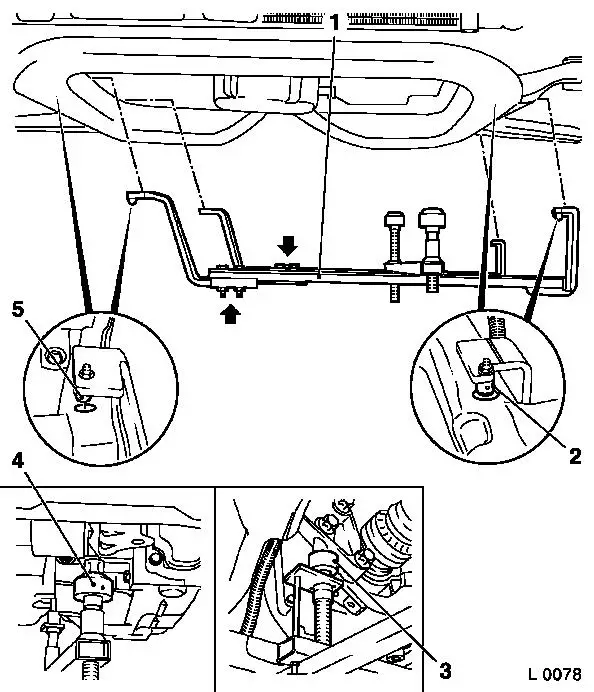

| 9. |

Attach KM-6001-B to front axle

body

| • |

Release 2x bolt (arrows) for adjustment rails on KM-6001-B (1)

|

| • |

Insert KM-6001-B as shown

Note: 2x journals (2)

and (5) must sit flush in the guide holes of the front axle

body.

|

| • |

Tighten 2x bolt for adjustment rails

|

| • |

Twist up front support bearing (4)

| – |

as far as the stop on the guide pin of the front engine damping

block

Note: The guide pins

must sit in the support bearings with no play.

|

|

| • |

Twist up rear support bearing (3)

| – |

as far as the stop on the guide pin of the rear engine damping

block bracket

Note: The guide pins

must sit in the support bearings with no play.

|

|

|

|

Important: KM-6001-B remains on front axle body and may not be

moved.

|

| 10. |

Remove front axle body

|

| 11. |

Detach right axle shaft from intermediate shaft

| • |

Attach axle shaft to vehicle underbody

|

|

| 12. |

Remove intermediate shaft

Note: Fluid escapes.

Place pan underneath.

|

| 13. |

Remove left axle shaft

| • |

Attach axle shaft to vehicle underbody

|

|

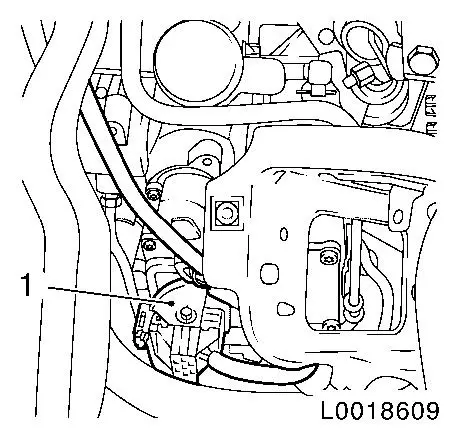

| 14. |

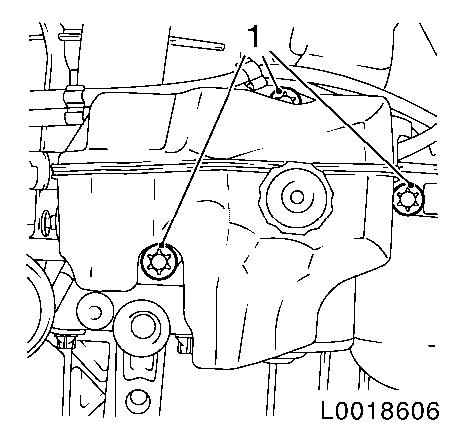

Remove front engine damping block

|

|

|

|

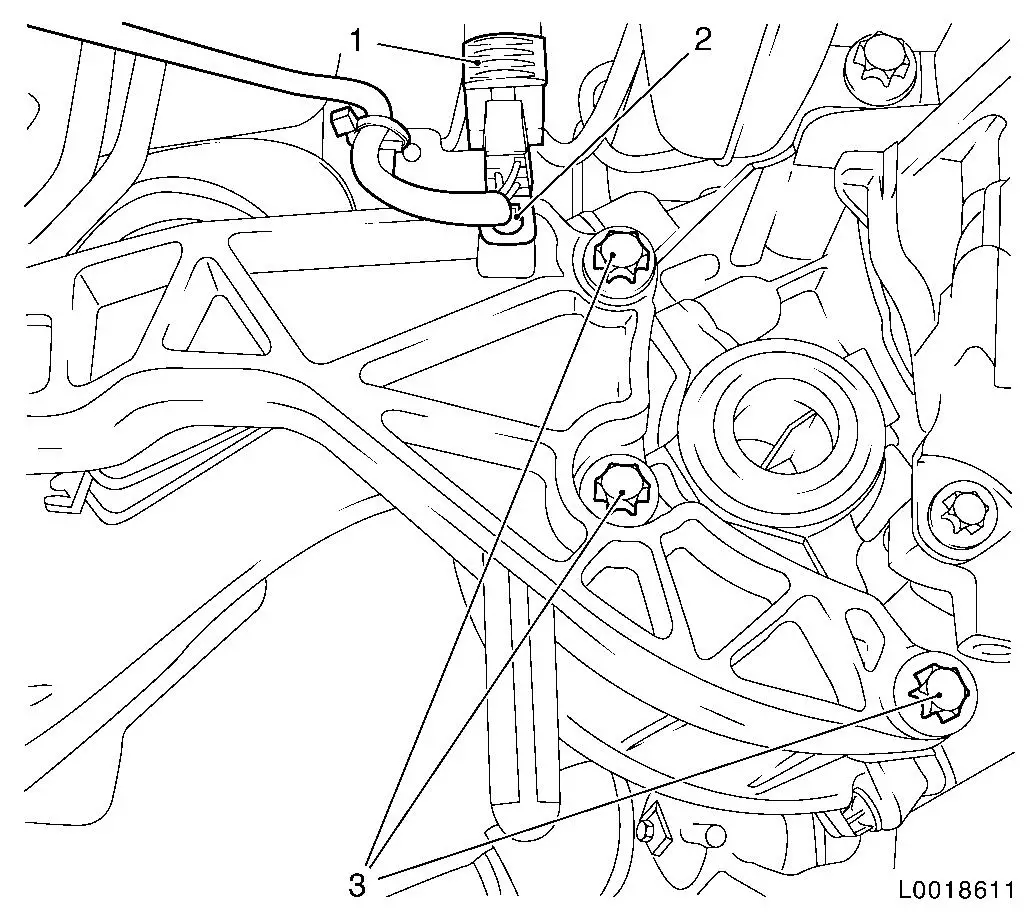

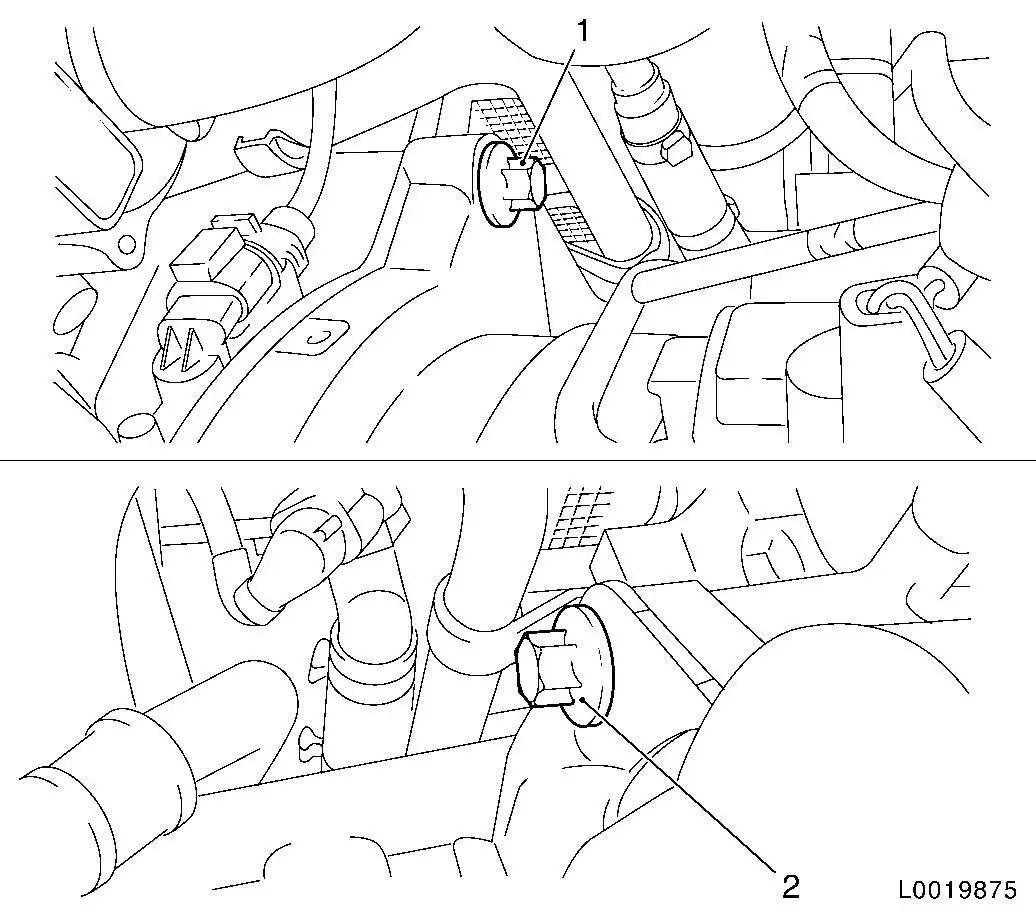

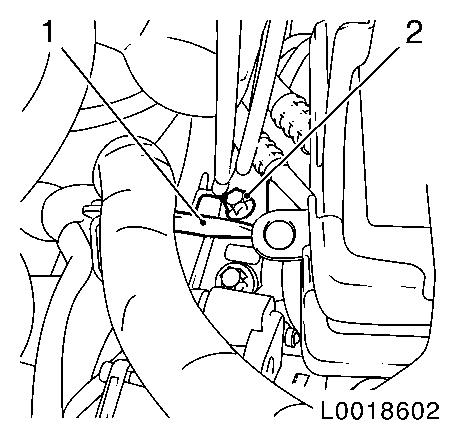

| 15. |

Remove rear engine damping block

| • |

Release wiring harness plug (1) and disconnect

|

| • |

Unscrew bolt (2) from wiring harness bracket

|

|

|

|

| 16. |

Detach left engine damping block from engine damping block

bracket

|

|

Important: Do not damage wiring

harnesses and attaching parts

Pay attention to the vacuum line on the throttle valve module.

|

| 17. |

Lower the engine and transmission on the left-hand side approx.

20 centimetres

|

|

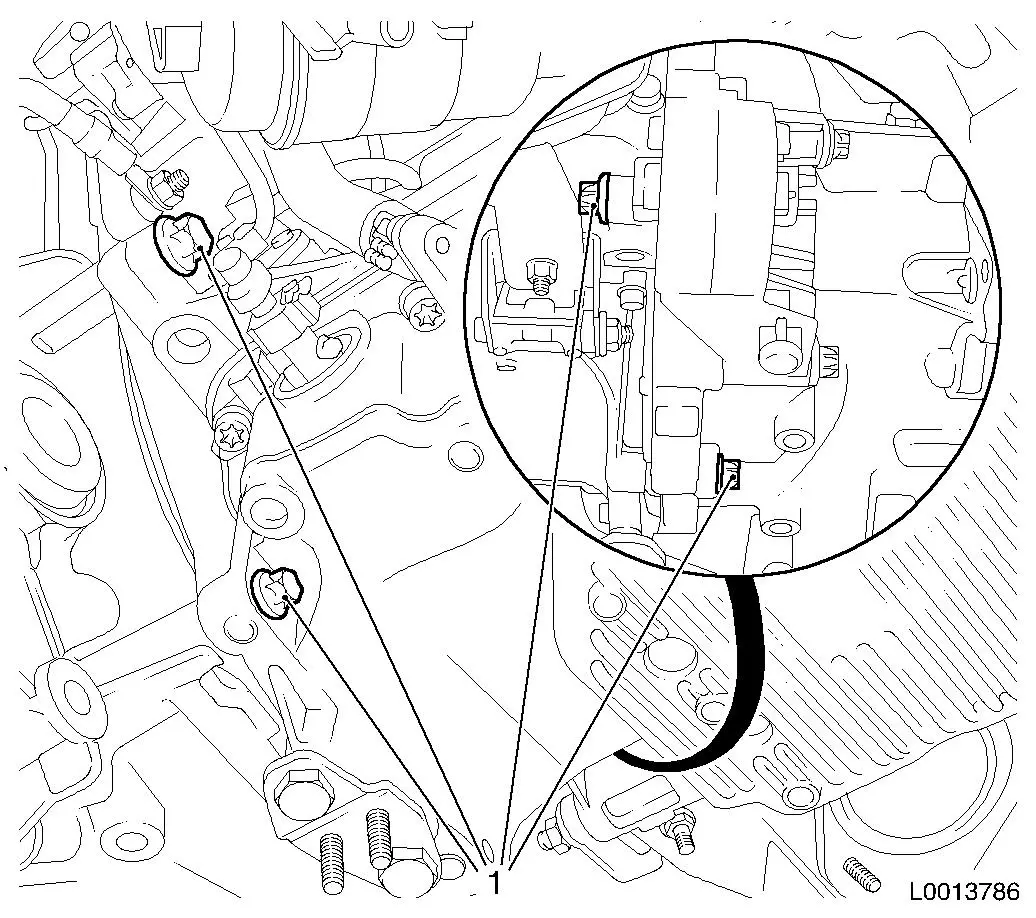

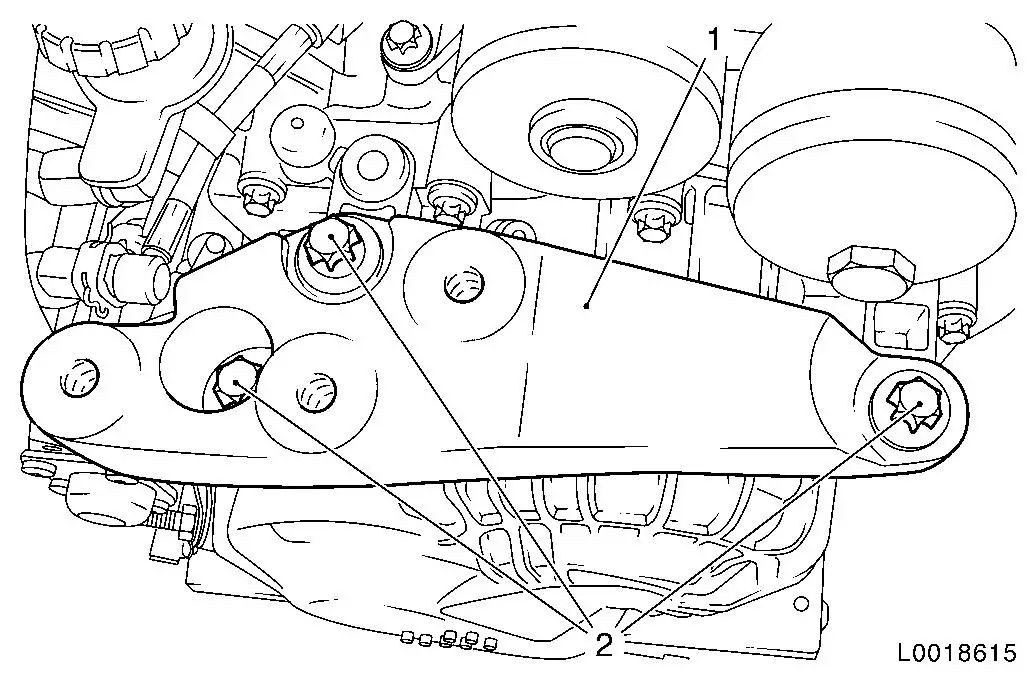

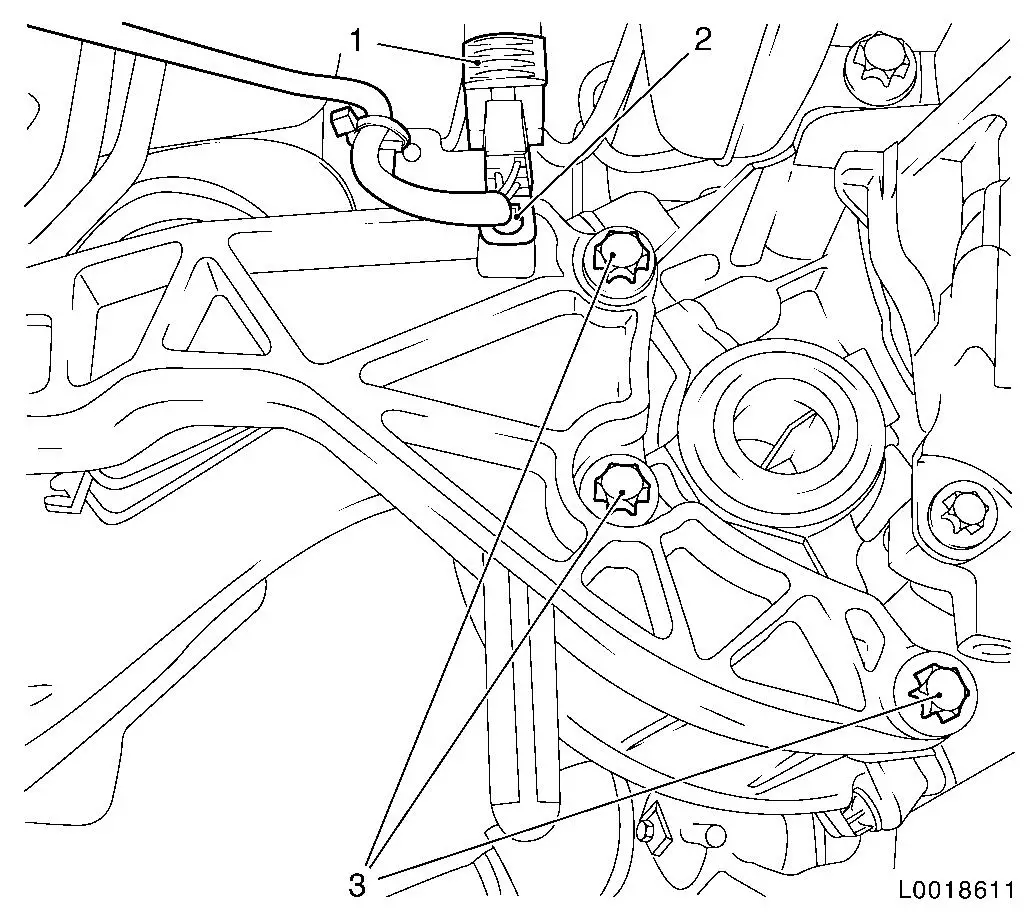

| 19. |

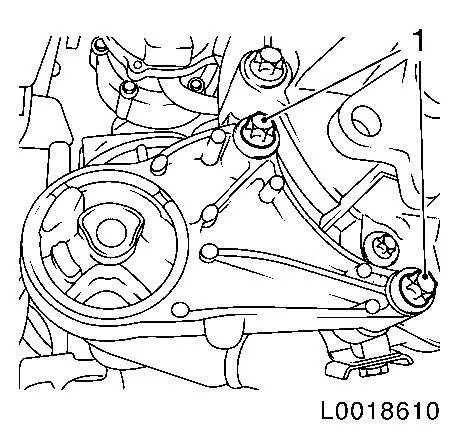

Release transmission at top

Note: With the vehicle

raised, release the upper transmission bolts from below.

| • |

Unscrew the front (1) and rear (2) upper transmission bolts

|

|

|

|

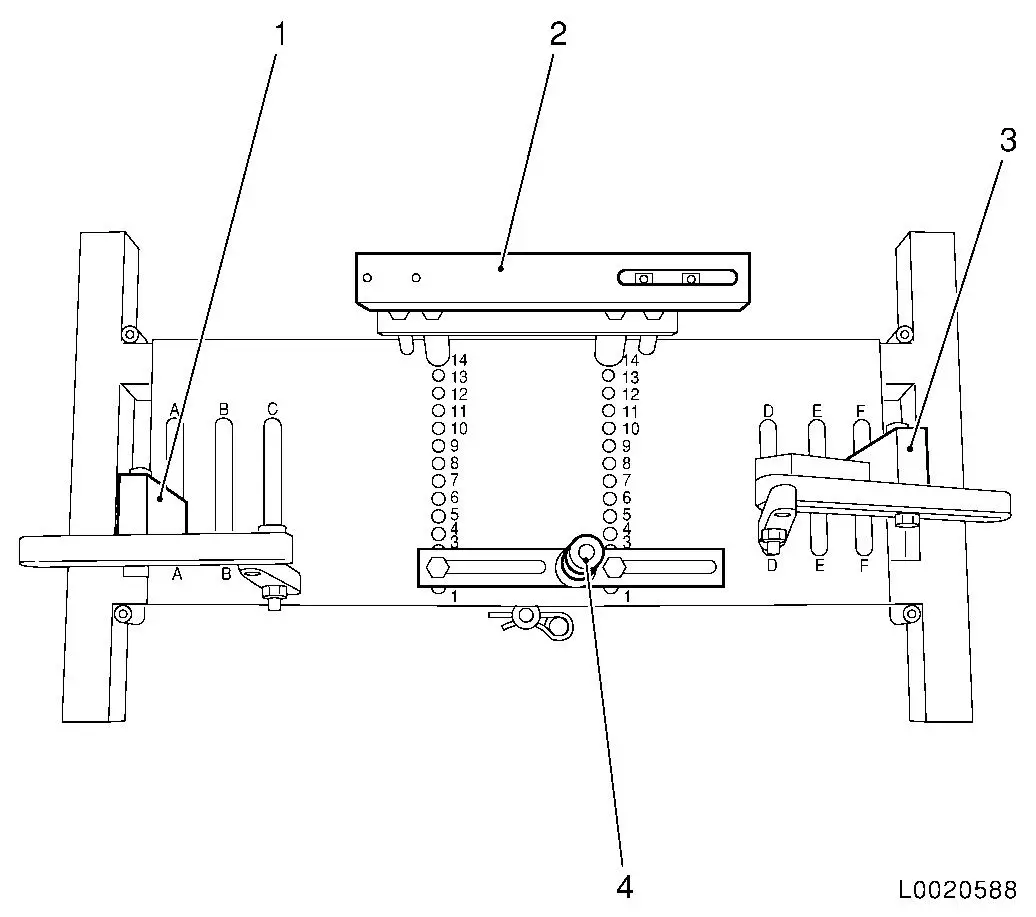

| 20. |

Place transmission holder DT-47648 on

KM-904 and preinstall as shown in the

illustration:

|

Component

|

Position on base plate

|

Designation

|

|

DT-47648-2

(4)

|

2

|

Clutch housing support

|

|

DT-47648-3

(2)

|

14

|

Transmission housing support

|

|

DT-47648-5 left

(1)

|

A

|

Support with rear transmission swivel arm

|

|

DT-47648-5 right

(3)

|

F

|

Support with front transmission swivel arm

|

|

|

Important: It is essential to

follow the manufacturer's instructions for transmission holder

DT-47648 .

|

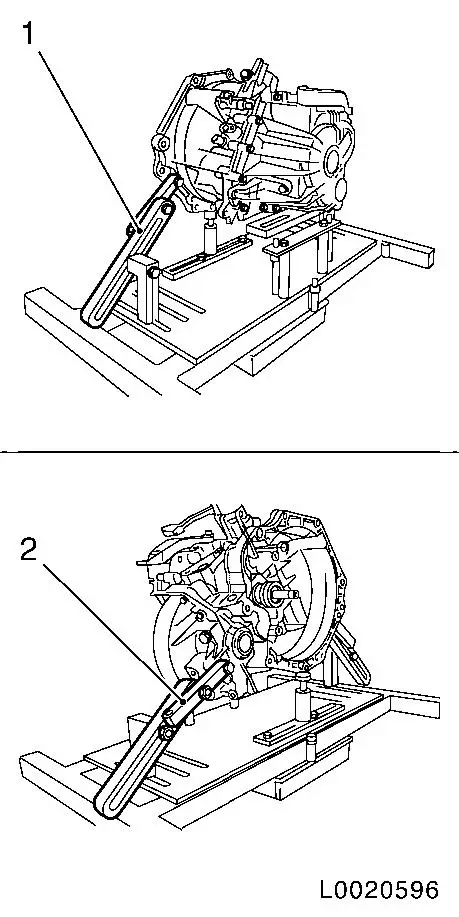

| 21. |

Attach DT-47648 to transmission

Note: Before placing in

position, slacken all bolt connections of the swivel arms and

supports as far as the base plate. Adjust the supports using the

spindles until they are as low as possible.

| • |

Place DT-47648 with supports in

position under the transmission

|

| • |

Tighten bolt connections of the supports

|

| • |

Attach swivel arm (1) and (2) to transmission

|

| • |

Tighten bolt connections of the swivel arms starting from the

transmission and going as far as the base plate

Note: Align the swivel

arms so that as little leverage as possible is created.

|

|

|

|

|

| 22. |

Remove transmission

| • |

Press transmission off engine and slowly lower the hydraulic

jack

Note: Do not damage

wiring harnesses and attaching parts

|

|

|

Important: Do not damage

attaching parts when putting the transmission down.

|

| 23. |

Detach transmission from transmission holder DT-47648

Note: 2nd mechanic

required.

| • |

Put transmission down carefully

|

|

|

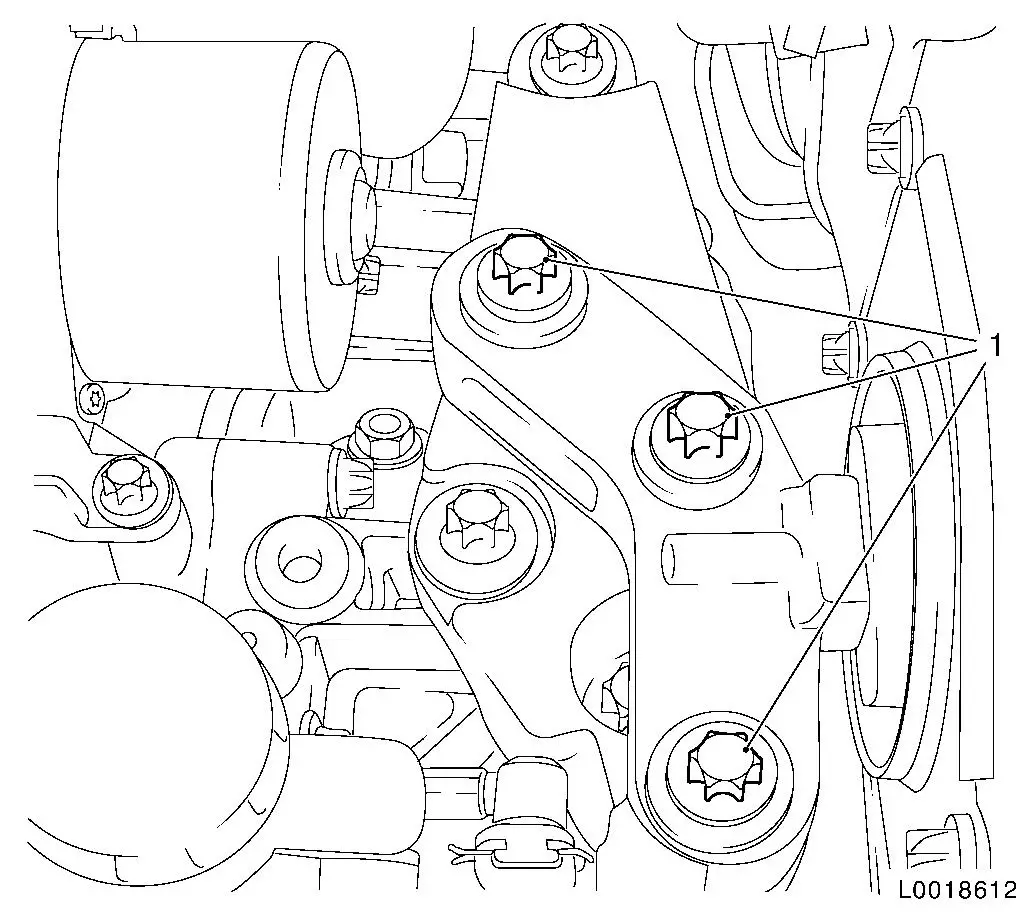

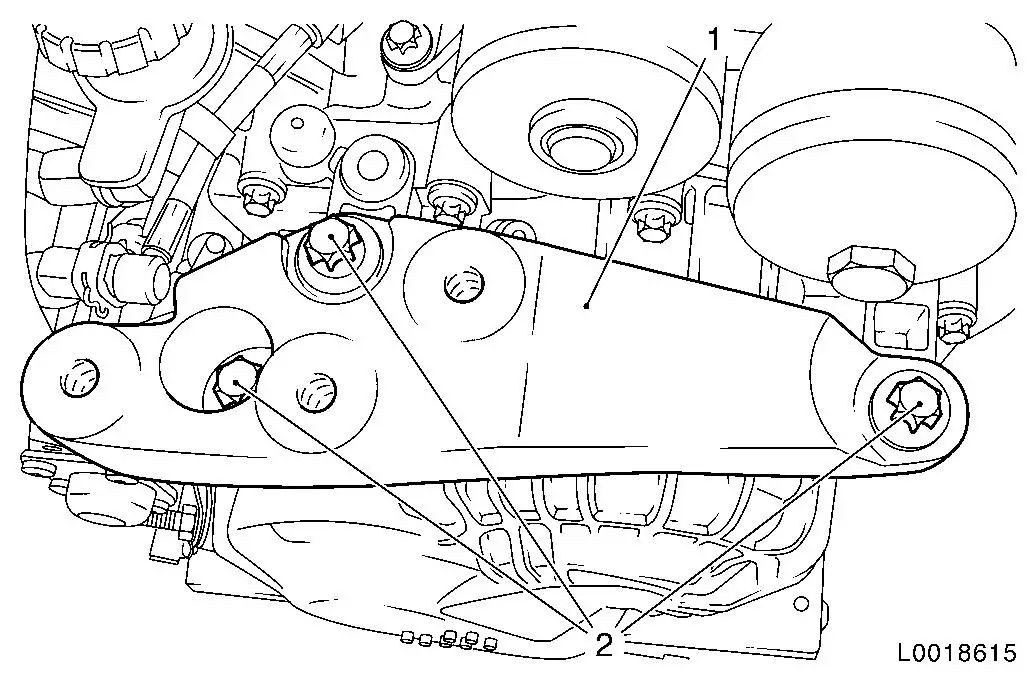

| 24. |

Detach left engine damping block bracket (1) from

transmission

Note: Only required if

the transmission is being exchanged.

|

|

Install

Install

|

| 25. |

Attach left engine damping block bracket (1) to

transmission

Note: Only required if

the transmission is being exchanged.

| • |

Tighten 3x bolt (2) 60 Nm

|

|

|

| 26. |

Attach transmission to transmission holder DT-47648

Note: 2nd mechanic

required.

|

| 27. |

Install transmission with DT-47648

| • |

Raise transmission and align it

|

| • |

Place transmission so that it is in even contact with the

engine

Note: Ensure it is

seated perfectly.

|

|

|

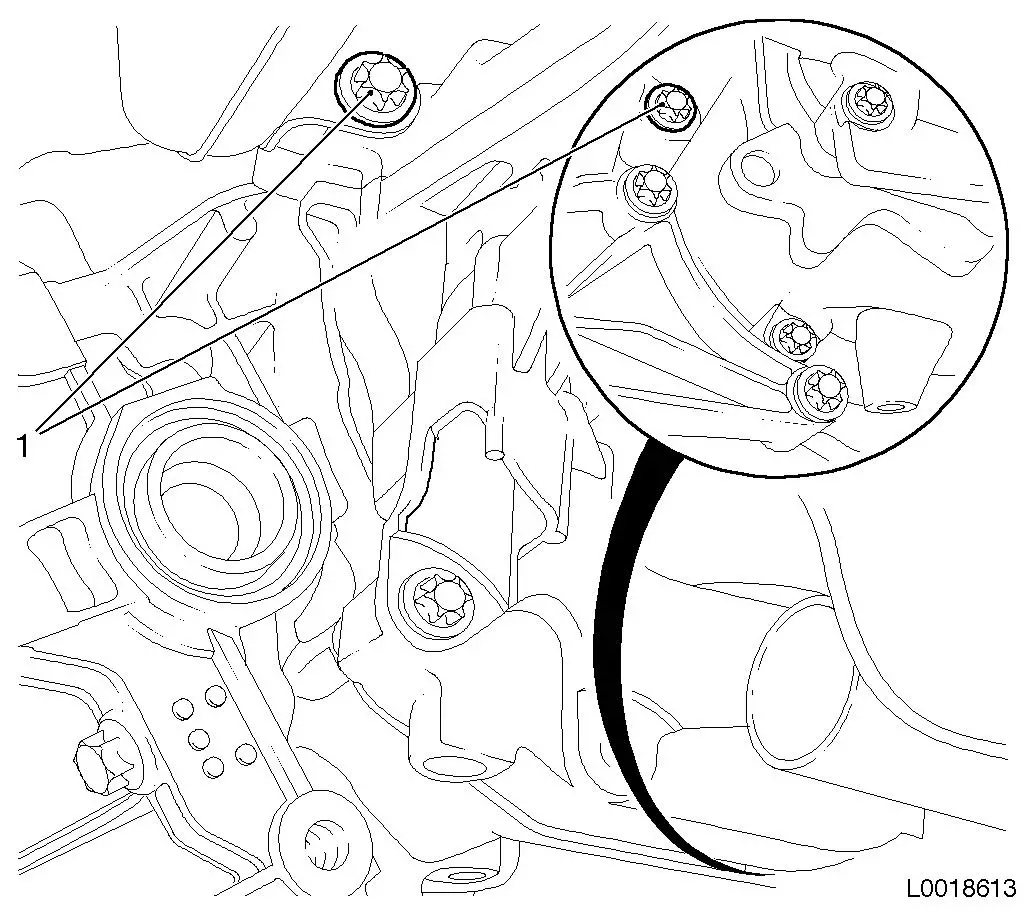

| 28. |

Fasten transmission at the bottom

| • |

Tighten 2x bolt M12 (1)

|

|

|

| 29. |

Detach transmission holder DT-47648

from transmission

| • |

Lower hydraulic jack with transmission holder DT-47648 and extend

|

|

|

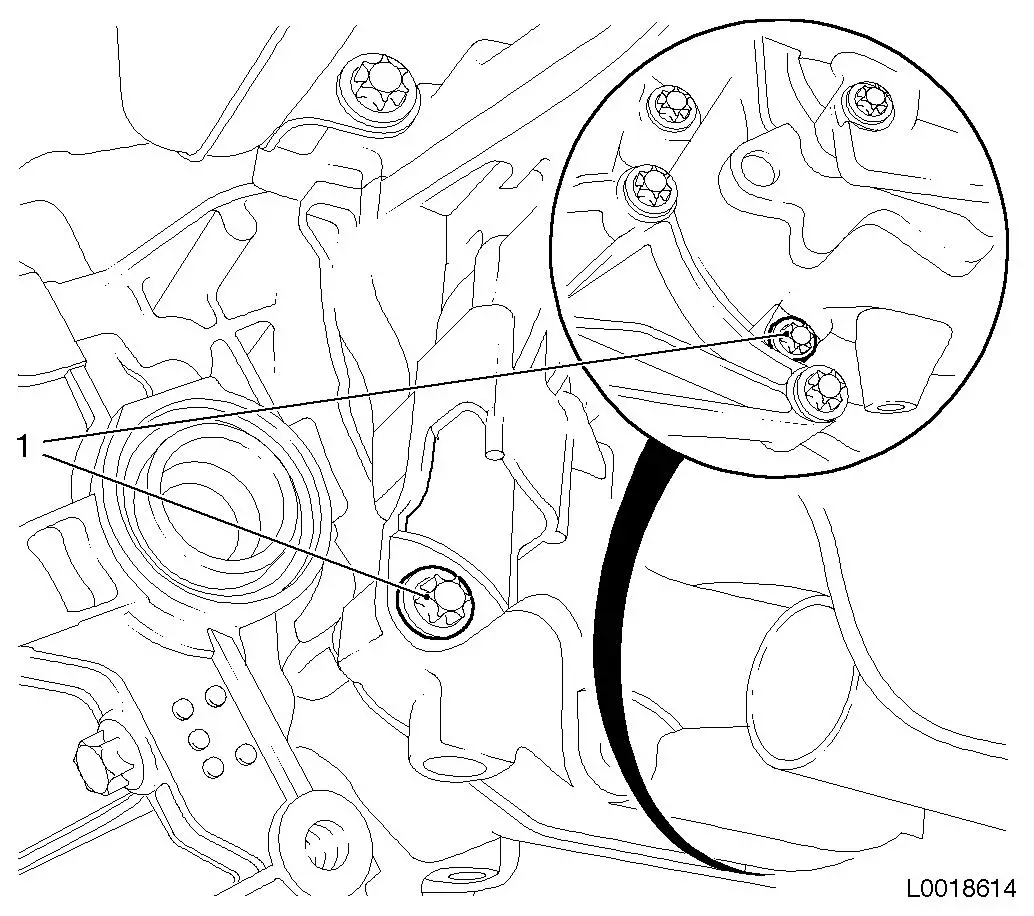

| 30. |

Fasten transmission at the bottom

| • |

Tighten 2x bolt M10 (1) 40 Nm

Note: Note differing

bolt lengths

|

|

|

|

| 31. |

Fasten transmission at top

Note: With the vehicle

raised, fasten the upper transmission bolts from below.

| • |

Tighten the front (1) and rear (2) M12 upper transmission bolts

60 Nm

|

|

|

Important: Do not damage wiring

harnesses and attaching parts

Pay attention to the vacuum line on the throttle valve module.

|

| 32. |

Raise engine and transmission on the left hand side

|

|

| 33. |

Attach the left engine damping block to the left engine damping

block bracket

| • |

Screw in 3 bolts (1) loosely

|

|

|

| 34. |

Attach left axle shaft

|

| 35. |

Install intermediate shaft

|

| 36. |

Attach right axle shaft to intermediate shaft

|

| 37. |

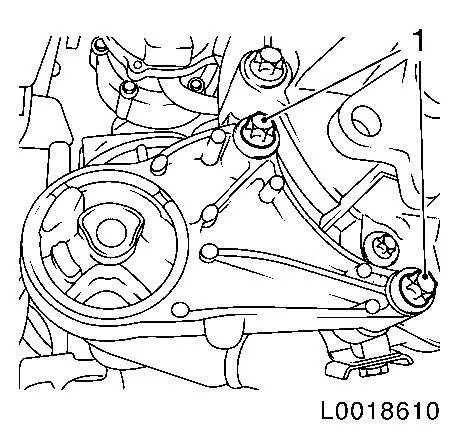

Install front engine damping block

| • |

Tighten 2x bolt (1) 80 Nm

|

|

|

|

|

| 38. |

Install rear engine damping block

| • |

Fasten wiring harness bracket

|

| • |

Connect and lock wiring harness plug (1)

|

|

|

| 39. |

Install front axle body

Note: Do not install

front exhaust pipe and central silencer yet.

|

|

| 40. |

Fasten left engine damping block

| • |

Tighten 3x bolt (1) 55 Nm

|

|

|

| 41. |

Detach engine bridge in conjunction with MKM-883-1-A and MKM-883-2

|

| 42. |

Detach KM-6001-B from front axle

body

|

| 43. |

Install exhaust system

|

| 44. |

Connect wiring harness, MTA-system

| • |

Connect and lock wiring harness plug (1)

|

|

|

|

| 45. |

Fasten MTA wiring harness bracket (2)

|

|

|

| 46. |

Fasten MTA system supply unit

| • |

Tighten 3x bolt (1) 10 Nm

Note: Note differing

bolt lengths

|

|

|

|

| 47. |

Attach battery wiring harness bracket (1) to MTA system supply

unit

|

|

|

| 48. |

Top up with transmission fluid

|

| 49. |

Install battery.

| • |

Install battery support

|

|

| 50. |

Fill coolant. Adjust level if necessary.

|

| 51. |

Program volatile memories

|

| 53. |

Necessary Start-Up Routines for Easytronic

|

| 54. |

Work to be carried out with Tech 2

|

|