Engine Compression Test

Special Tools

| • |

EN-46783

Thread Adapter |

| • |

EN-46791

Adapter, Compression Tool |

For equivalent regional tools refer to

Special Tools .

Removal Procedure

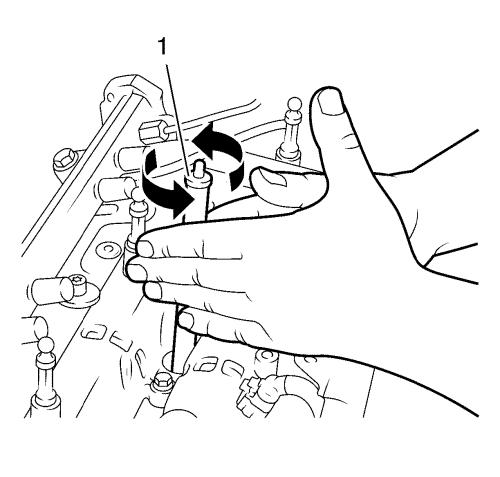

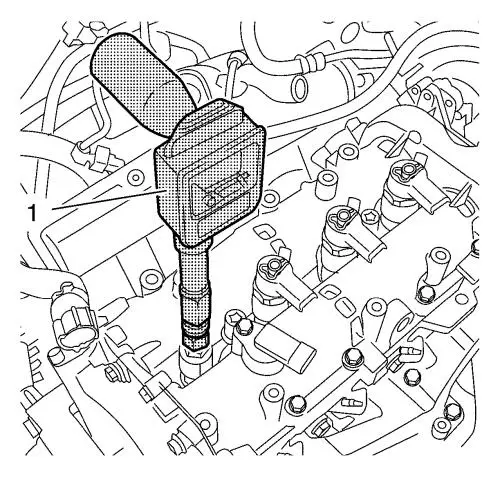

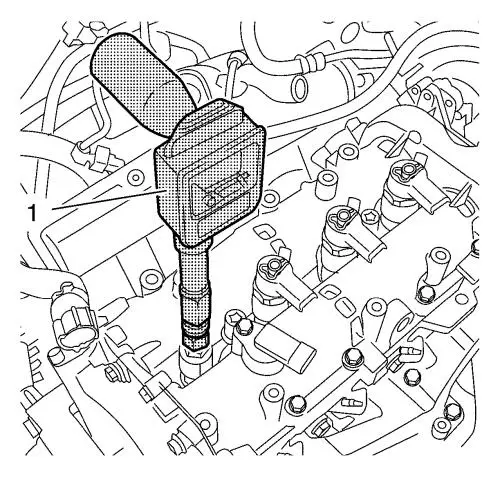

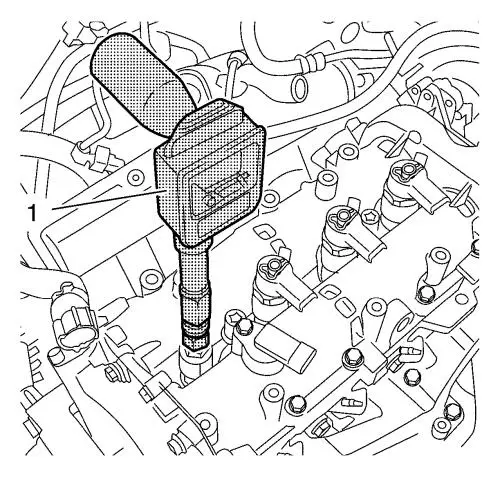

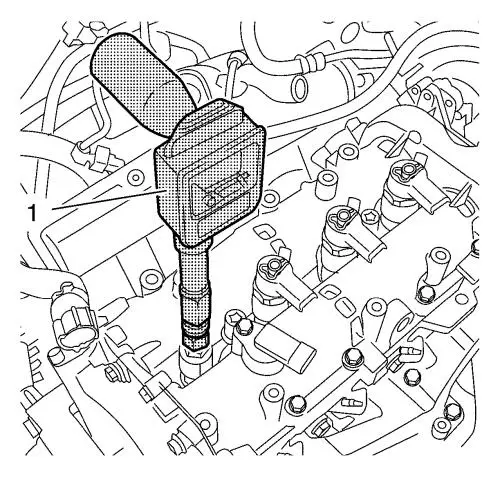

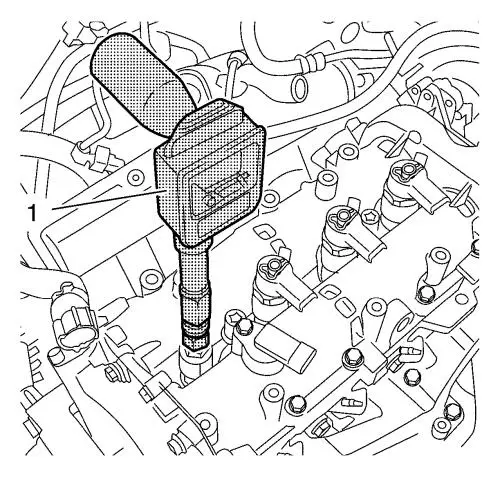

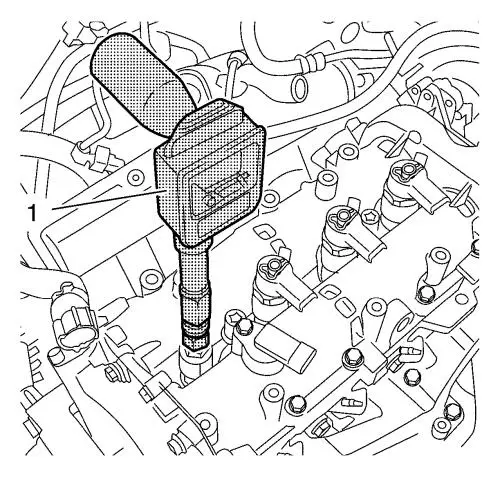

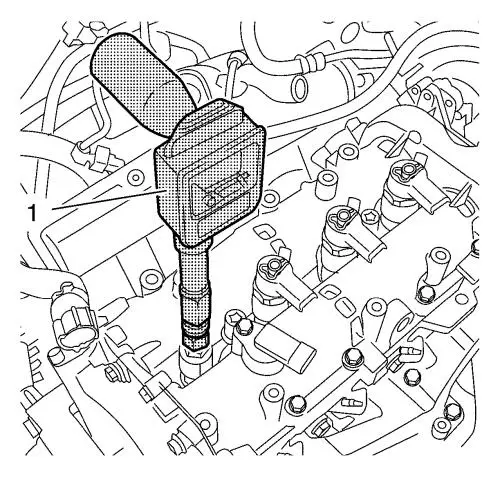

| 3. |

Clean the injector sealing

surfaces in the cylinder head using EN-47632

cleaning tool (1) in following procedure: |

| |

• |

first take the brush side to

loosen the dirt. |

| |

• |

second take the sponge side to

remove the dirt. |

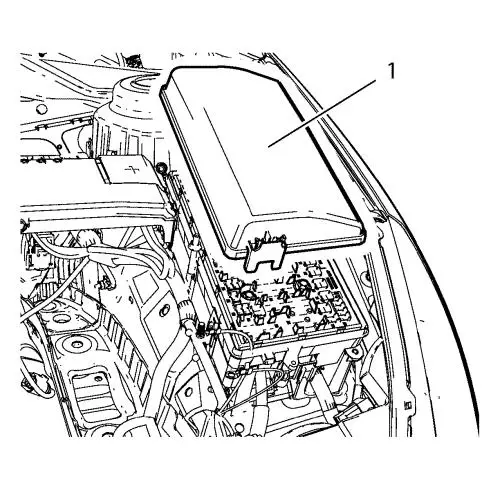

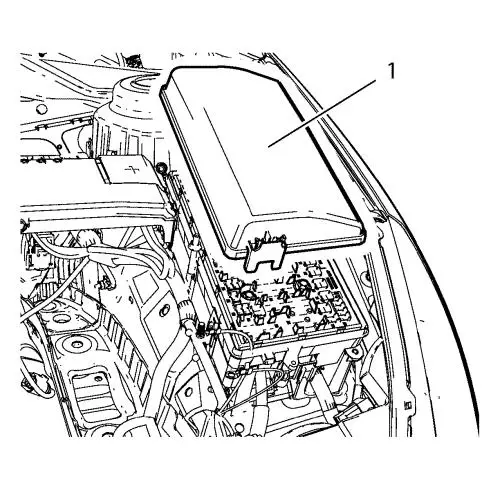

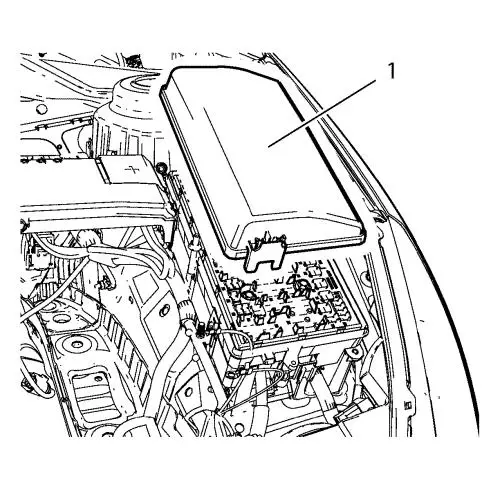

| 4. |

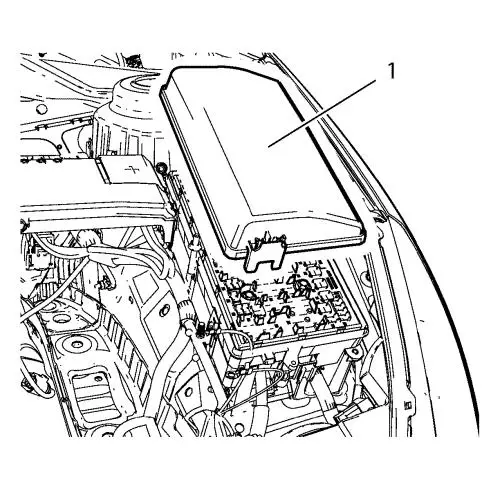

Remove the front compartment

fuse block cover (1). |

| 5. |

Remove the fuel pump

relay. |

Compression Test Cylinder 1

|

Note: EN-46791 adapter can only be installed in

pairs along with the fuel injector (cylinder 1 and 2 or cylinder 3

and 4).

|

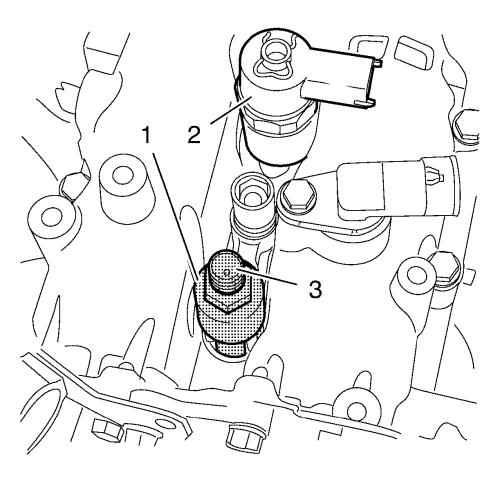

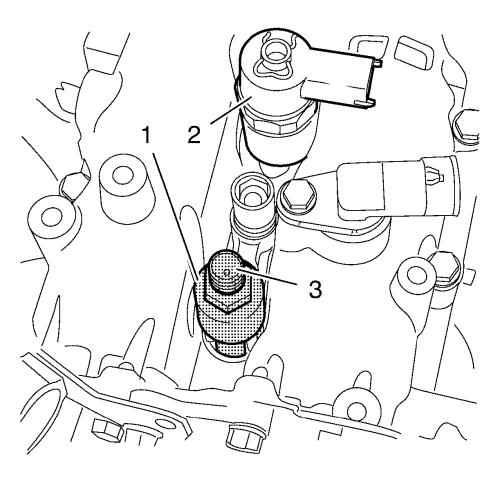

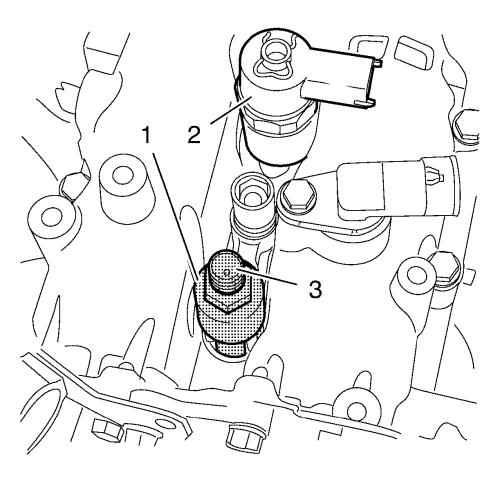

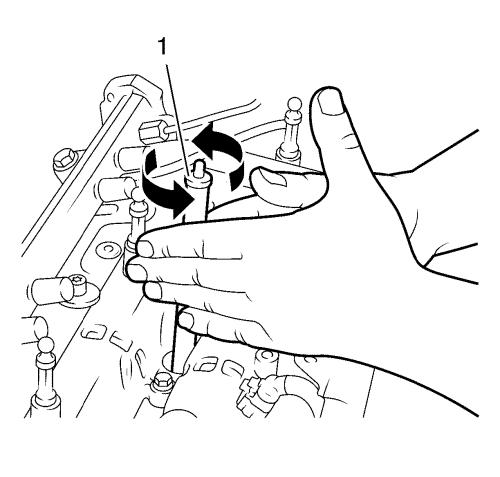

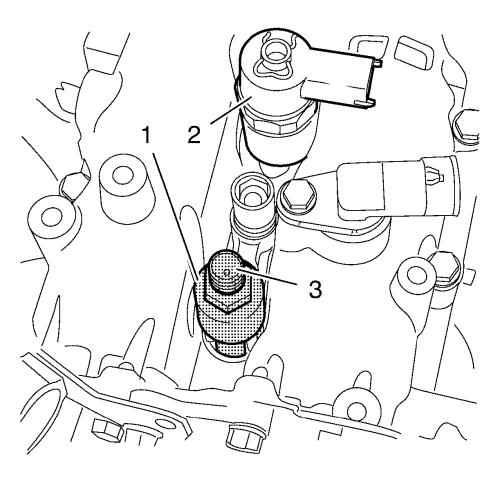

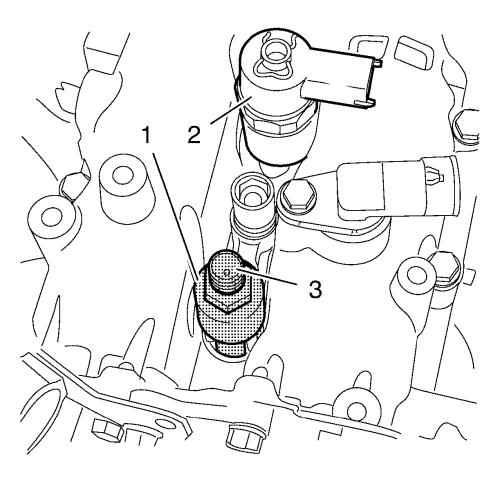

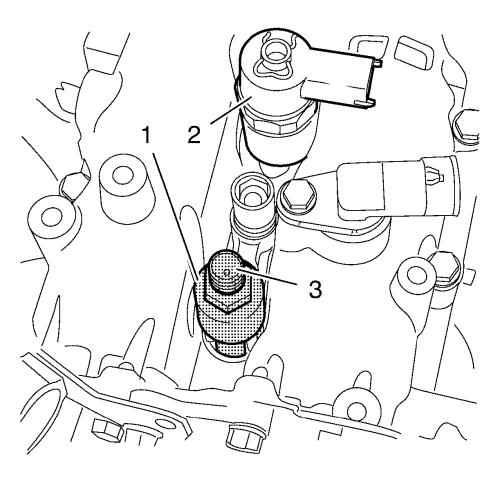

| 1. |

Install EN-46791

adapter (1) with fuel injector (2) and fuel injector bracket

in cylinder 1 with a NEW fuel injector gasket. |

| 2. |

Install fuel injector

spherical washer |

| 3. |

Install fuel injector conical

washer |

| 4. |

Install fuel injector bracket

nut and tighten to 20 N·m (15 lb ft)

. |

| 5. |

Install EN-46783

thread adapter (3) to EN-46791 adapter

(1). |

|

Note: Use a

compression plotter with a measuring range of 10-40

bar (145- 580 PSI).

|

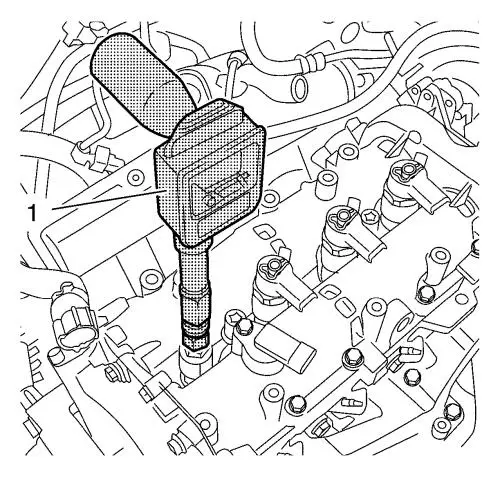

| 6. |

Install compression plotter to

EN-46783 thread adapter . |

| 8. |

Check the compression of

cylinder 1. |

|

Note: A second

technician is required.

|

| |

Start engine for approximate 4 seconds. |

|

Note: Engine speed at

least 200 RPM.

|

| 9. |

Remove EN-46791

adapter (1) from cylinder 1. |

Compression Test Cylinder 2

|

Note: EN-46791 adapter can only be installed in

pairs along with the fuel injector (cylinder 1 and 2 or cylinder 3

and 4).

|

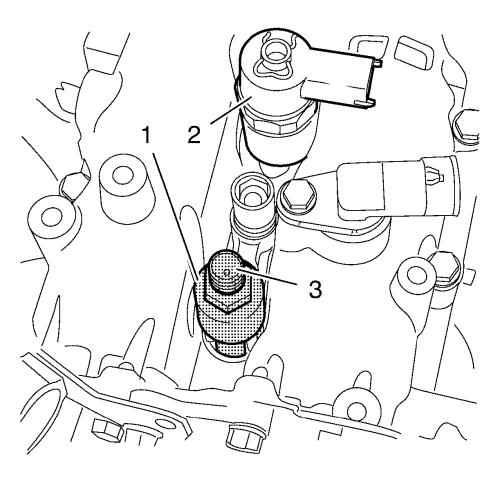

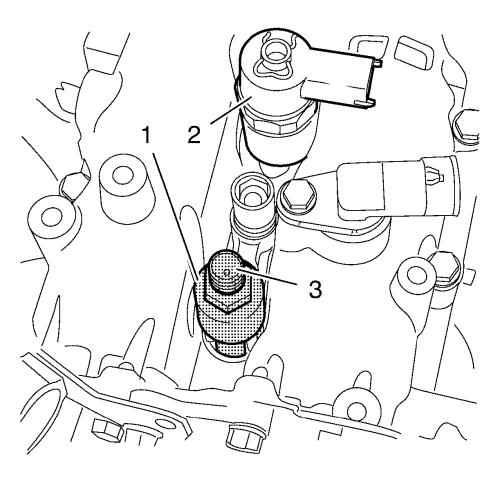

| 1. |

Install EN-46791

adapter (1) with fuel injector (2) and fuel injector bracket

in cylinder 2 with a NEW fuel injector gasket. |

| 2. |

Install fuel injector

spherical washer. |

| 3. |

Install fuel injector conical

washer. |

| 4. |

Install fuel injector bracket

nut and tighten to 20 N·m (15 lb ft)

. |

| 5. |

Install EN-46783

thread adapter (3) to EN-46791 adapter

(1). |

|

Note: Use a

compression plotter with a measuring range of 10-40

bar (145- 580 PSI).

|

| 6. |

Install compression plotter to

EN-46783 thread adapter . |

|

Note: A second

technician is required.

|

| 7. |

Check the compression of

cylinder 2. |

|

Note: Engine speed at

least 200 RPM.

|

| 8. |

Start engine for approximate 4

seconds. |

|

Note: A second

technician is required.

|

| 9. |

Check the compression of

cylinder 2 |

| 10. |

Remove EN-46791

adapter (1) from cylinder 2. |

Compression Test Cylinder 3

|

Note: EN-46791 adapter can only be installed in

pairs along with the fuel injector (cylinder 1 and 2 or cylinder 3

and 4).

|

| 1. |

Install EN-46791

adapter (1) with fuel injector (2) and fuel injector bracket

in cylinder 3 with a NEW fuel injector gasket. |

| 2. |

Install fuel injector

spherical washer. |

| 3. |

Install fuel injector conical

washer. |

| 4. |

Install fuel injector bracket

nut and tighten to 20 N·m (15 lb ft)

. |

| 5. |

Install EN-46783

thread adapter (3) to EN-46791 adapter

(1). |

|

Note: Use a

compression plotter with a measuring range of 10-40

bar (145- 580 PSI).

|

| 6. |

Install compression plotter to

EN-46783 thread adapter . |

| 7. |

Check the compression of

cylinder 3. |

|

Note: A second

technician is required.

|

| |

Start engine for approximate 4 seconds. |

|

Note: Engine speed at

least 200 RPM.

|

| 8. |

Remove EN-46791

adapter (1) from cylinder 3. |

Compression Test Cylinder 4

|

Note: EN-46791 adapter can only be installed in

pairs along with the fuel injector (cylinder 1 and 2 or cylinder 3

and 4).

|

| 1. |

Install EN-46791

adapter (1) with fuel injector (2) and fuel injector bracket

in cylinder 4 with a NEW fuel injector gasket. |

| 2. |

Install fuel injector

spherical washer. |

| 3. |

Install fuel injector conical

washer. |

| 4. |

Install fuel injector bracket

nut and tighten to 20 N·m (15 lb ft)

. |

| 5. |

Install EN-46783

thread adapter (3) to EN-46791 adapter

(1). |

|

Note: Use a

compression plotter with a measuring range of 10-40

bar (145- 580 PSI).

|

| 6. |

Install compression plotter to

EN-46783 thread adapter . |

| 7. |

Check the compression of

cylinder 4 |

|

Note: A second

technician is required.

|

| |

Start engine for approximate 4 seconds. |

|

Note: Engine speed at

least 200 RPM.

|

| 8. |

Remove EN-46791

adapter (1) from cylinder 4. |

|

Note: Maximum

pressure difference 1.5 bar (22 PSI).

|

| 9. |

Compare compression values

from cylinder 1-4 |

Installation Procedure

| 2. |

Install the fuel pump

relay. |

| 3. |

Install the front compartment

fuse block cover (1) |

|