Piston, Connecting Rod, and Bearing Cleaning and Inspection

(LDC, LDD, LWD, L2I, L2N)

Special Tools

EN-470-B Angular Torque Wrench

For equivalent regional tools, refer to

Special Tools .

Visual Inspection And Cleaning Procedure

Connecting Rod

|

Warning:

Wear safety glasses when using compressed air in

order to prevent eye injury. |

| 1. |

Clean the connecting rods in

solvent and dry with compressed air. |

| 2. |

Inspect the connecting rod for

the following: |

| |

• |

Signs of being twisted, bent,

nicked or cracked |

| |

• |

Scratches or abrasion on the

connecting rod bearing seating surfaces |

Piston

| 1. |

Clean the piston with a

cleaning solvent. DO NOT wire brush any parts of the piston.

|

| 2. |

Clean the piston ring

grooves. |

| 3. |

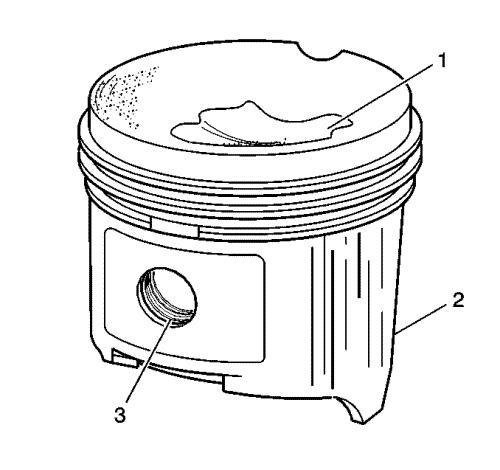

Inspect the piston on the

following: |

| |

• |

Cracked ring lands, skirts or

pin bosses |

| |

• |

Eroded areas on the top of the

piston (1) |

| |

• |

Scuffed or damaged skirts

(2) |

| |

• |

Worn piston pin bores

(3) |

| 4. |

If there is any excessive

wear, replace the piston. |

| 5. |

Measure the clearance between

piston pin and piston bore. |

Piston And Connecting Rod Measurement Procedure

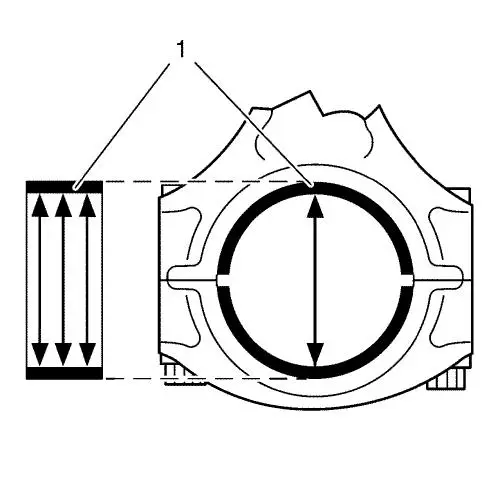

Piston Ring Clearance

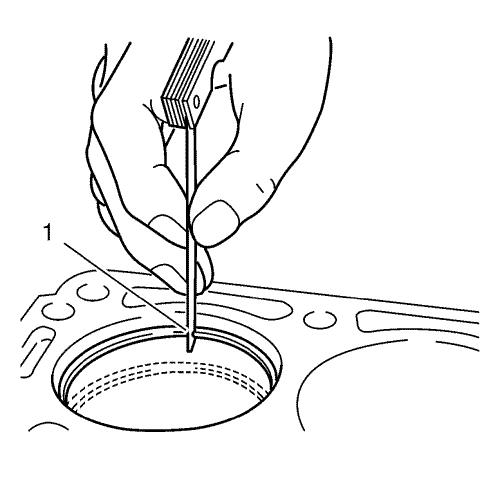

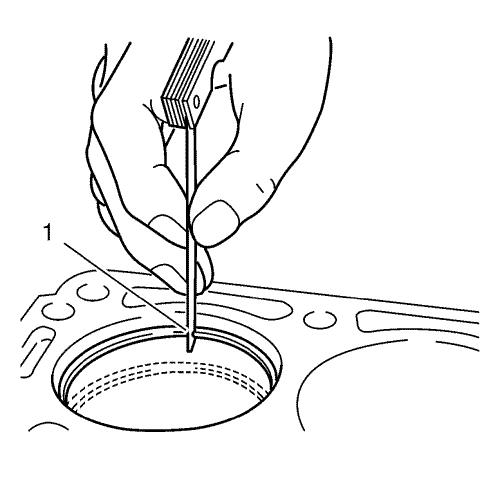

| 1. |

Install the piston rings to

the cylinder as shown and measure the piston ring end gap. Compare

the measurements with those provided below: |

| |

• |

The upper compression ring end

gap should be 0.25 mm-0.400 mm (0.0098 in-0.0158

in) . |

| |

• |

The oil ring end gap should be

0.250 mm-0.750 mm (0.0098 in-0.0295 in) .

|

| 2. |

If the clearance is greater

than the provided specifications, the piston rings must be

replaced. |

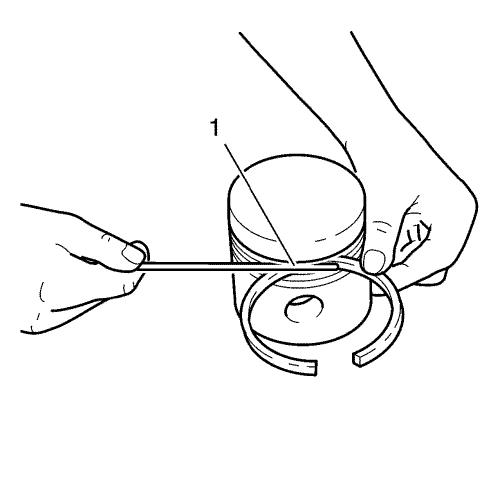

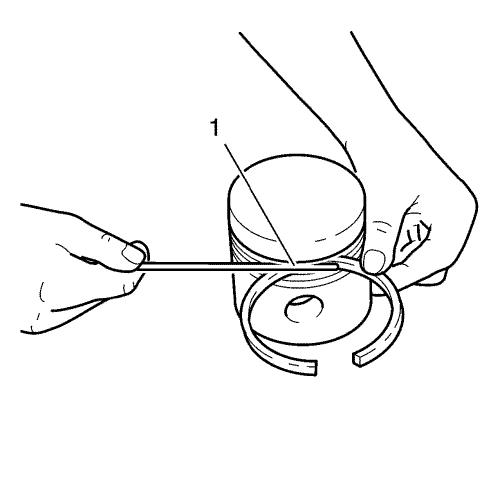

| 3. |

Measure the piston ring side

clearance as shown. Compare the measurements with those provided

below: |

| |

• |

The upper compression ring

side clearance should be 0.025 mm-0.07 mm (0.001 in-0.0028

in) . |

| |

• |

The oil ring side clearance

should be 0.04 mm-0.12 mm (0.0016 in-0.0047 in)

. |

| 4. |

If the clearance is greater

than the provided specifications, replace the piston rings.

|

| 5. |

If the clearance is still too

great, replace the pistons. |

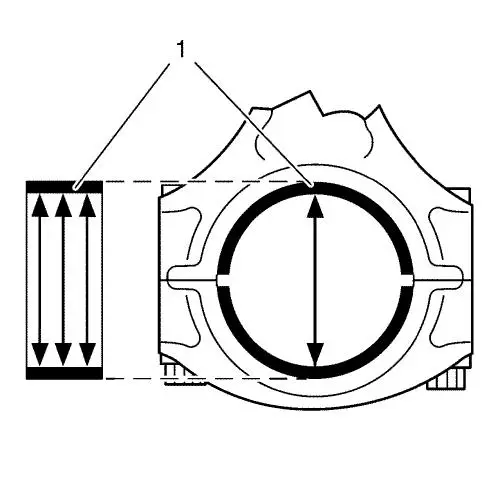

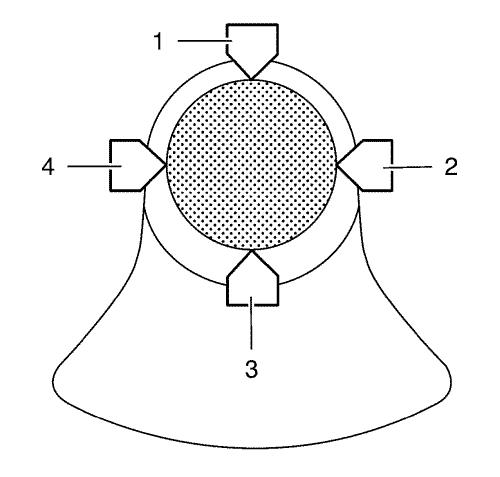

Connecting Rod Bearing Clearance (With Micrometer Gauge

Internal Measuring Device)

| 1. |

Install the connecting

bearings and the connecting rod bearing caps. |

| 2. |

Tighten the connecting rod

bearing cap bolts in the following sequence: |

|

Note: The old bolts can be

reused for the measuring procedure.

|

| |

2.1 |

Tighten the connecting rod

bearing cap bolts to 10 N·m (89 lb in)

. |

| |

2.2 |

Tighten the bolts to an

additional 60° , using EN-470-B

wrench . |

| |

2.3 |

Tighten the bolts to an

additional 15° , using EN-470-B

wrench . |

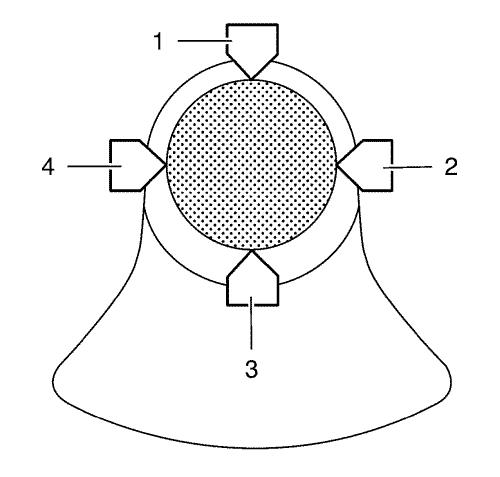

| 3. |

Measure the connecting rod

bearing diameters at 3 points as shown (1). Use a internal

measuring device. |

| 4. |

Calculate the average

connecting rod inner diameter. |

| |

Formula: 1. result + 2. result + 3. result / 3 |

| 5. |

Measure the connecting rod

journal diameter at 2 points between 1 and 3 and between 2 and 4.

Use a micrometer gauge. |

| 6. |

Calculate the average

connecting rod journal diameter. |

| |

Formula: 1. result + 2. result / 2. |

| 7. |

Subtract the average

connecting rod journal diameter from the average connecting rod

bearing diameter in order to determine the connecting rod bearing

clearance. |

| |

The clearance should be 0.013 mm-0.061 mm (0.0005

in-0.0024 in) . |

|