Piston, Connecting Rod, and Bearing Replacement

Special Tools

| • |

EN-45059

Torque Angle Sensor |

| • |

CH-49290

Mounting Engine / Transmission |

For equivalent regional tools, refer to

Special Tools .

Removal Procedure

| 5. |

Remove the CH-49290

mounting , for disassembly use attached installation

manual. |

| 7. |

Set crankshaft to TDC of

combustion stroke of cylinder 1. |

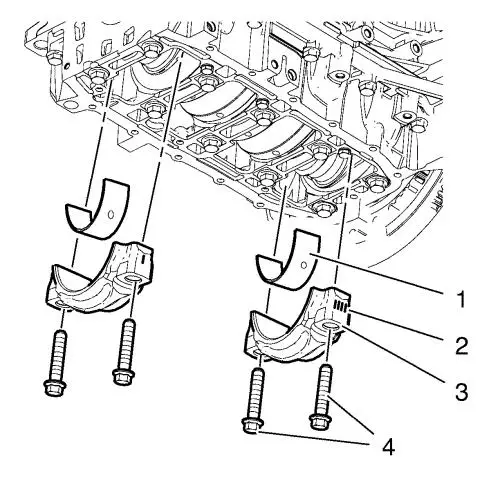

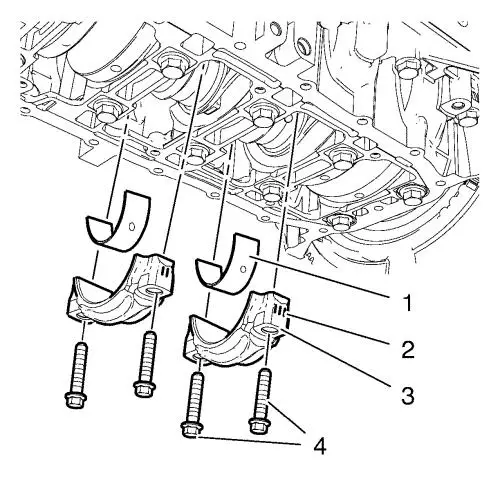

| 8. |

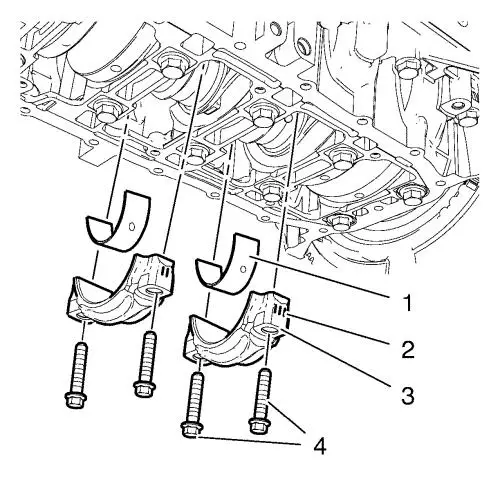

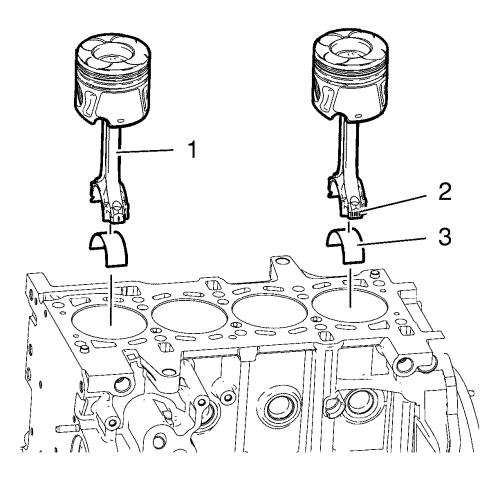

Remove and DISCARD the 4

connecting rod bearing cap bolts (4) from the cylinder 2 and

3. |

|

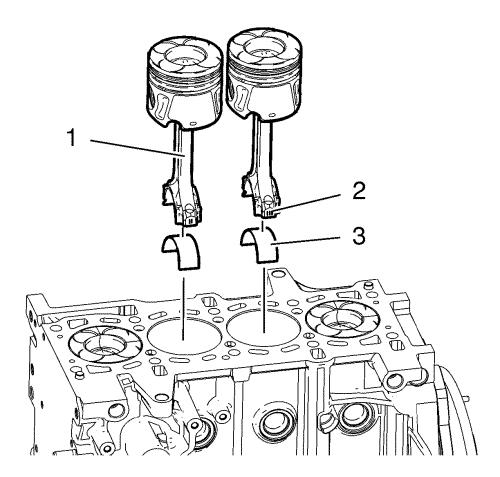

Note: Note the

marking (2) of the connecting rod bearing caps.

|

|

Note: The shear

surfaces of the connecting rod and the connecting rod bearing cap

form a unique fit and must not be swapped or damaged. Do not lay

down on the shear surfaces.

|

| 9. |

Remove the 2 connecting rod

bearing caps (3) from the cylinder 2 and 3. |

| 10. |

Remove the 2 connecting rod

lower bearings (1). |

|

Note: Set aside in

the order removed.

|

|

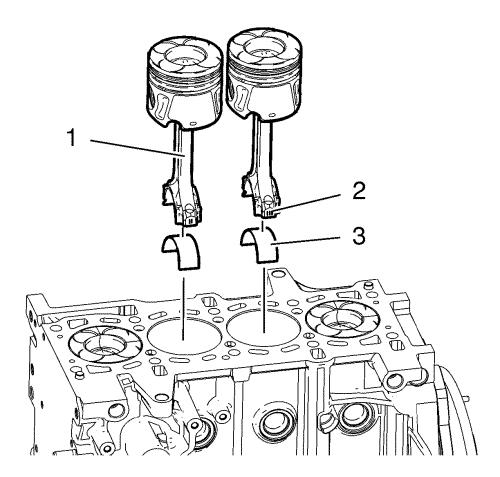

Note: Take extreme

care to prevent damage to the cylinder bore surface, piston ring

and piston surface.

|

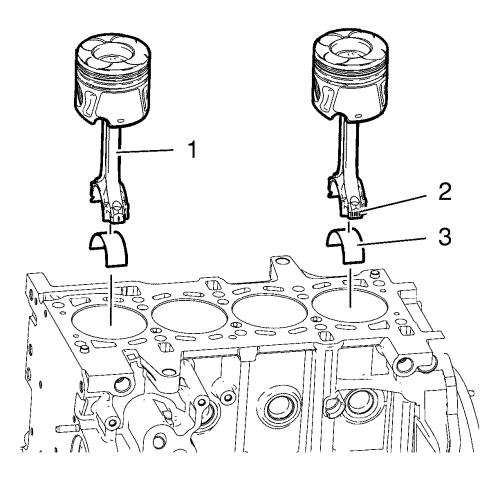

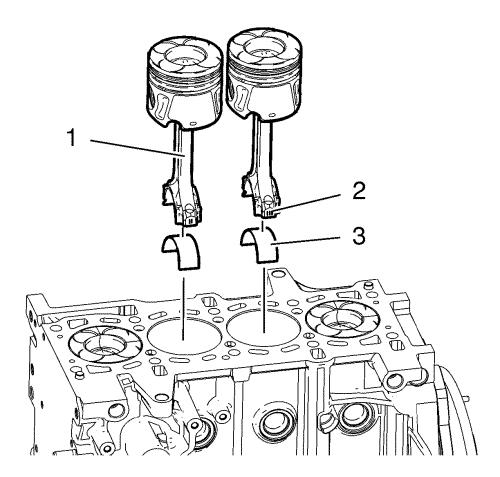

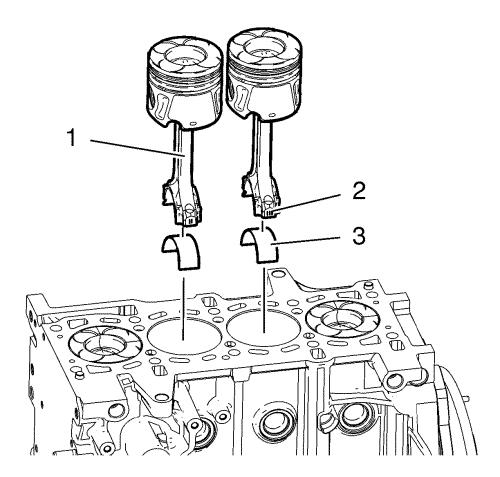

| 12. |

Push the 2 pistons with

connecting rod (1) from the cylinder 2 and 3 upwards. |

|

Note: Note the

marking (2) of the connecting rod. Set aside in the order

removed.

|

| 13. |

Remove the 2 connecting rod

upper bearings (3) from the cylinder 2 and 3. |

| 14. |

Turn the crankshaft through

180° and set the crankshaft to TDC of

combustion stroke of cylinder 2. |

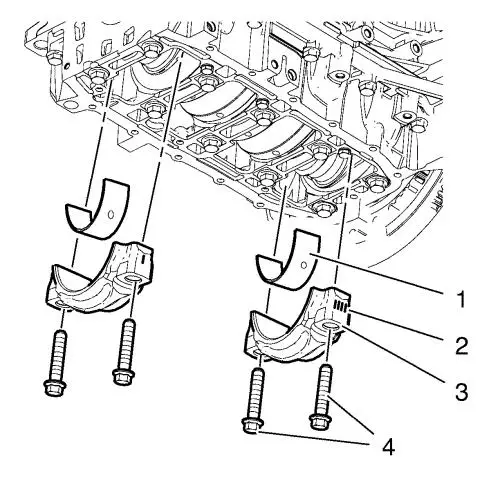

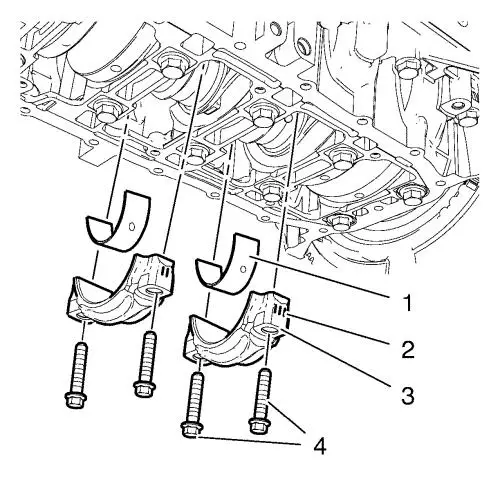

| 16. |

Remove and DISCARD the 4

connecting rod bearing cap bolts (4) from the cylinder 1 and

4. |

|

Note: Note the

marking (2) of the connecting rod bearing caps. Set aside in the

order removed.

|

|

Note: The shear

surfaces of the connecting rod and the connecting rod bearing cap

form a unique fit and must not be swapped or damaged. Do not lay

down on the shear surfaces.

|

| 17. |

Remove the 2 connecting rod

bearing caps (3) from the cylinder 1 and 4. |

|

Note: Set aside in

the order removed.

|

| 18. |

Remove the 2 connecting rod

lower bearings (1). |

|

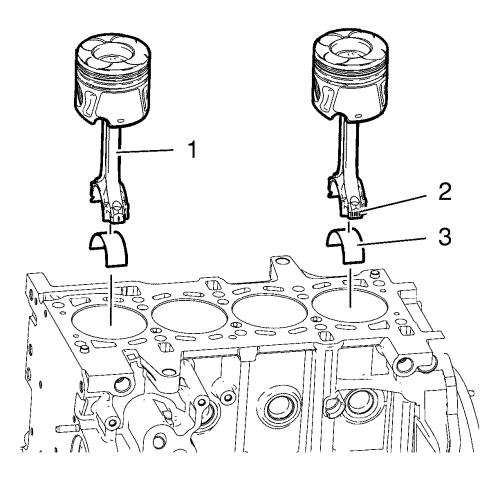

Note: Take extreme

care to prevent damage to the cylinder bore surface, piston ring

and piston surface.

|

| 19. |

Push the 2 pistons with

connecting rod (1) from the cylinder 1 and 4 upwards. |

|

Note: Note the

marking (2) of the connecting rod. Set aside in the order

removed.

|

| 20. |

Remove the 2 connecting rod

upper bearings (3) from the cylinder 1 and 4. |

Installation Procedure

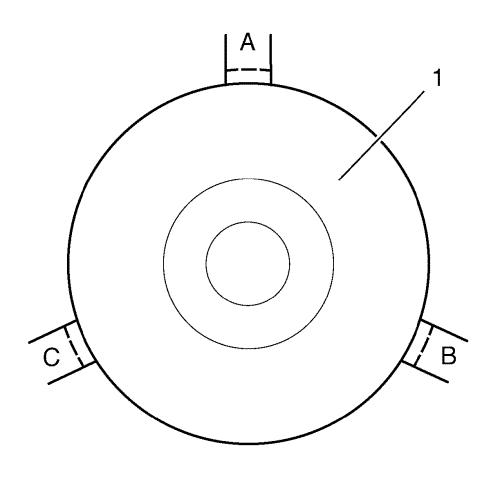

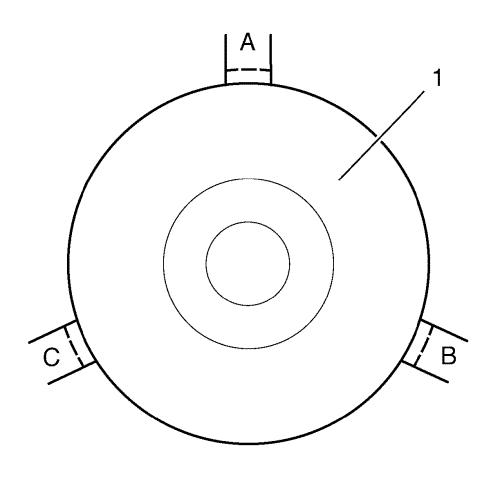

| 2. |

Turn the piston rings before

the installation to a position (A, B C) as in the graphic

shown. |

|

Note: Arrow on piston

head points to engine timing side.

|

| 3. |

Lubricate the piston rings,

piston, inner cylinder bore surface and a piston ring with clean

engine oil. |

| 4. |

Install the piston ring

compressor in order to compress the piston rings. |

|

Note: Take extreme

care to prevent damage to the cylinder bore surface, piston ring

and piston surface.

|

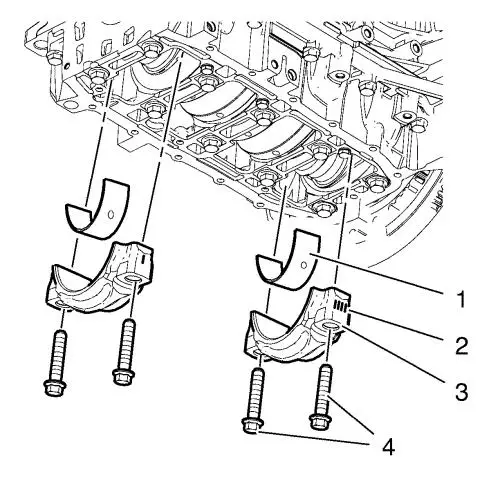

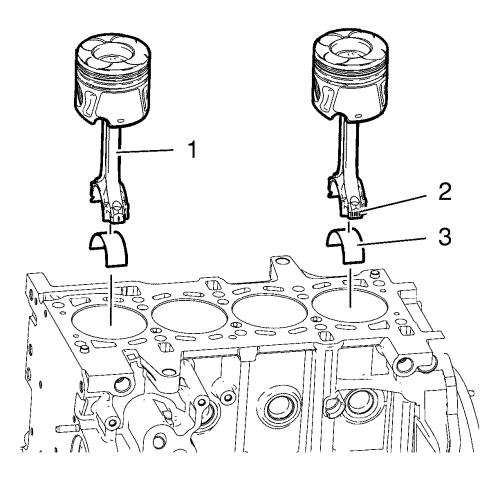

| 5. |

Install the 2 connecting rod

upper bearings (3) to the connecting rod of the cylinder 2 and

3. |

| |

Push the 2 pistons with connecting rod (1) to the cylinder 1

and 4. |

|

Note: Take extreme

care to prevent any scratches or damages to the connecting rod

bearings.

|

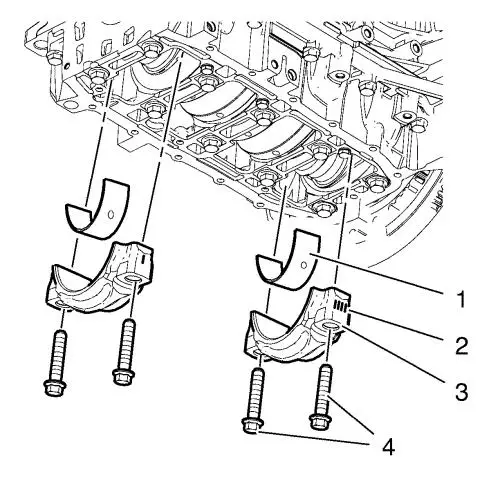

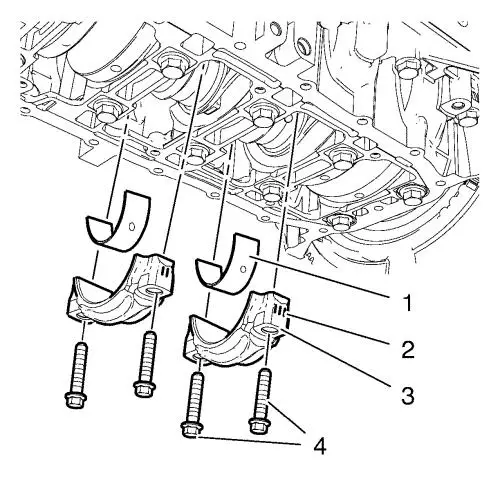

| 7. |

Install the 2 connecting lower

bearings (1). |

| 8. |

Install the 2 connecting rod

bearing caps (3) to the cylinder 1 and 4. |

| 9. |

Install the 4 NEW connecting

rod bearing cap bolts (4) to the cylinder 1 and 4 and tighten in

two passes: |

| |

• |

First pass to 25

N·m (18 lb ft) . |

| |

• |

Second pass to

60° , using the EN-45059

sensor . |

| 10. |

Turn the crankshaft through

180° and set crankshaft to TDC of combustion

stroke of cylinder 2. |

|

Note: Take extreme

care to prevent damage to the cylinder bore surface, piston ring

and piston surface.

|

| 12. |

Install the 2 connecting rod

upper bearings (3) to the connecting rod of the cylinder 2 and

3. |

| 13. |

Push the 2 pistons with

connecting rod (1) to the cylinder 2 and 3. |

|

Note: Take extreme

care to prevent any scratches or damages to the connecting rod

bearings.

|

| 15. |

Install the 2 connecting rod

lower bearings (1). |

| 16. |

Install the 2 connecting rod

bearing caps (3) to the cylinder 2 and 3. |

| 17. |

Install the 4 NEW connecting

rod bearing cap bolts (4) to the cylinder 2 and 3 and tighten in

two passes: |

| |

• |

First pass to 25

N·m (18 lb ft) . |

| |

• |

Second pass to

60° , using the EN-45059

sensor . |

| 18. |

Set the crankshaft in

direction of the engine rotation to 60° before

TDC of combustion stroke of cylinder 1. |

| 20. |

Install the CH-49290

mounting , for assembly use attached installation

manual. |

|