|

Remove and install crankshaft (Z 12 XE, Z 12 XEP,

Z 14 XEP, without air conditioning)

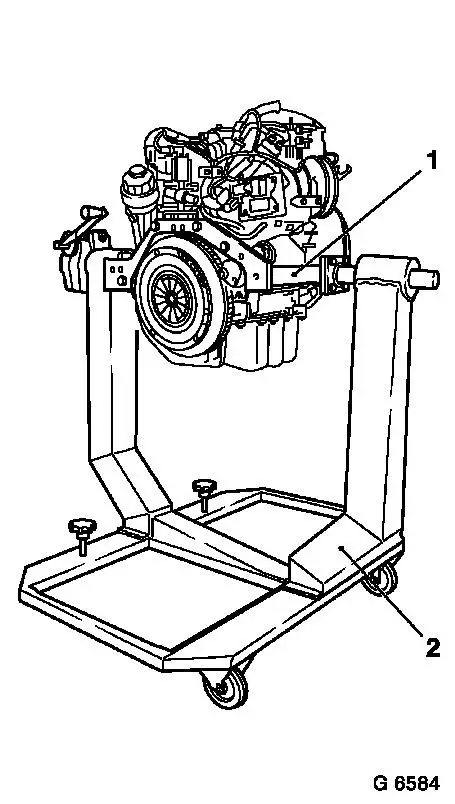

Remove Remove

| 1. |

Remove and install engine - See operation J 340100 "Removing

and installing engine" in group "J"

|

| 2. |

Removing and installing manual transmission from engine - see

operation "J 340100-007 Manual transmission to engine, remove and

install"

|

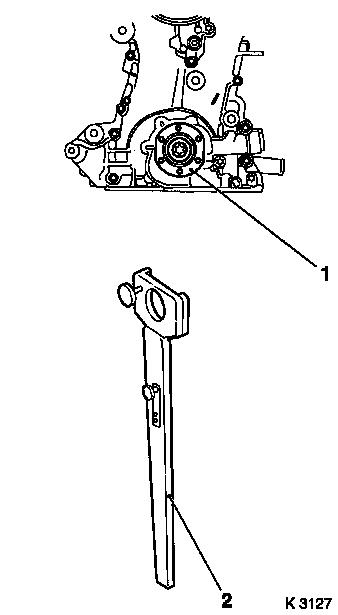

| 3. |

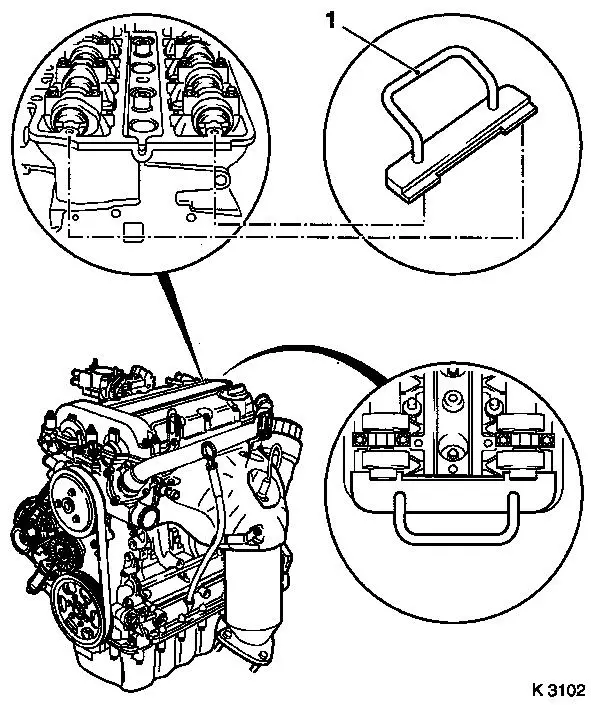

Install engine

| • |

Attach KM-412-18 (1) to engine

|

| • |

Install engine in KM-412 (2)

| – |

Tighten 8 bolted connections

|

|

|

| 4. |

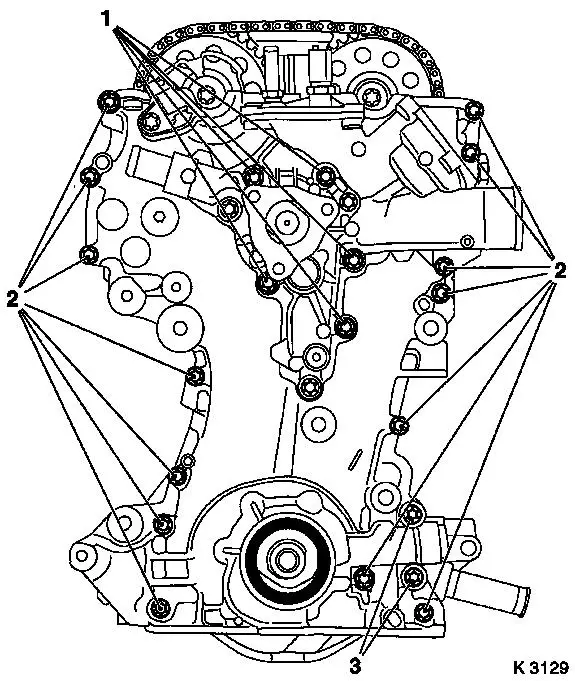

Drain engine oil

| • |

Place collecting basin underneath.

|

| • |

Remove oil filter housing cover

|

| • |

Remove oil filter element

|

|

|

|

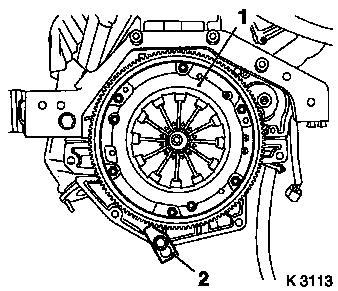

| 5. |

Detach clutch (1) - see operation "Remove and install thrust

plate and clutch disk" in group "K"

|

| 7. |

Detach right engine bracket

|

| 8. |

Install oil drain screw

|

|

|

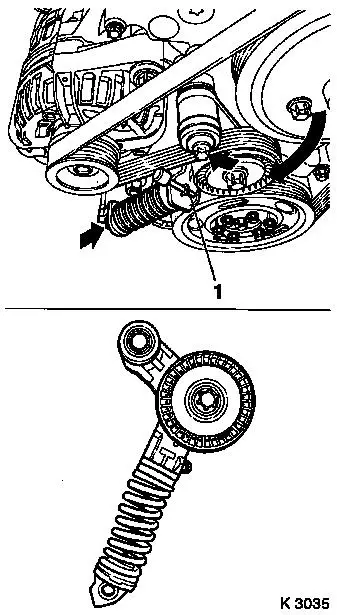

| 9. |

Remove ribbed V-belt

Note: Mark running

direction.

| • |

Tension ribbed V-belt tensioner in direction of arrow

|

| • |

Remove from crankshaft ribbed V-belt pulley

|

|

| 10. |

Detach coolant pump ribbed V-belt pulley

|

| 11. |

Detach crankshaft ribbed V-belt pulley

| • |

Counterhold at crankshaft hub bolt

|

|

| 12. |

Detach ribbed V-belt tensioner

| • |

Unscrew 2 bolts (arrows)

|

|

|

|

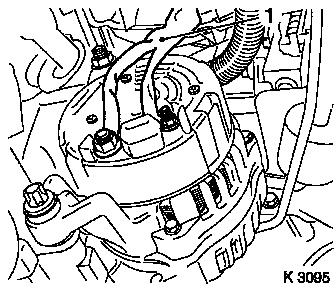

| 13. |

Remove alternator wiring harness (1)

|

|

|

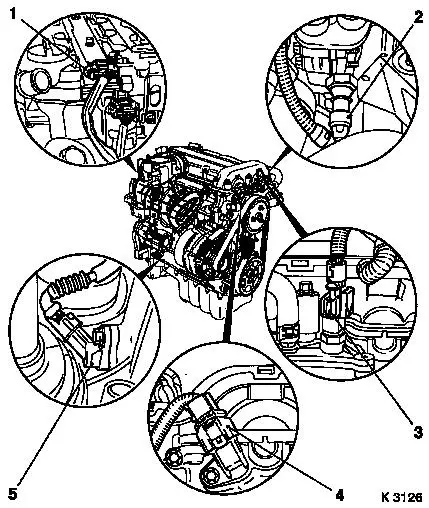

| 15. |

Remove wiring harness for engine management

| • |

Disconnect wiring harness connector.

| – |

Oil pressure switch (2), coolant temperature sensor (3),

camshaft sensor (4) ignition module (1), crankshaft sensor (5)

|

|

|

| 16. |

Detach 3 coolant hoses from coolant pump

|

|

|

| 17. |

Detach coolant pump (1)

Note: Note guide

bushings during removal

| • |

Place collecting basin underneath.

|

| • |

Unscrew 9 bolts

Note: Pay attention to

different bolt lengths (arrows = short bolts)

|

|

|

|

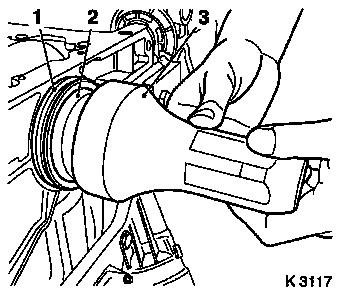

| 18. |

Remove ignition module

| • |

Remove ignition module cover

|

| • |

Extract using KM-6009 (1)

Note: Do not tilt

|

|

| 19. |

Unscrew 4x spark plugs with KM-194-E

|

| 20. |

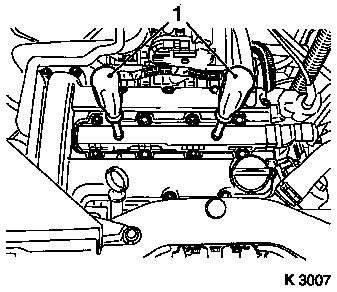

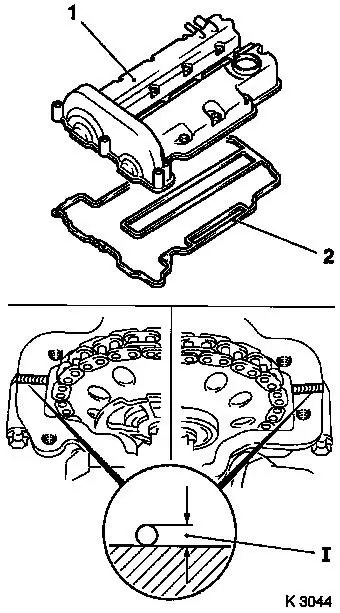

Detach cylinder head cover

| • |

Detach engine vent hose

|

|

|

|

| 21. |

Loosen crankshaft hub bolt (1)

Note: Second person

required

| • |

Attach KM-956-1 KM-956-2 (2)

|

| • |

Counterhold KM-956-1 KM-956-2

|

|

|

|

| 22. |

Adjust camshafts

| • |

Uniformly rotate crankshaft in direction of engine rotation

with KM-956-1 KM-956-2 until KM-953 (1)

engages in camshaft groove as far as it will go

|

|

| 23. |

Remove crankshaft hub

Note: Pay attention to

installation position

| • |

Remove with KM-956-1 KM-956-2

|

|

|

|

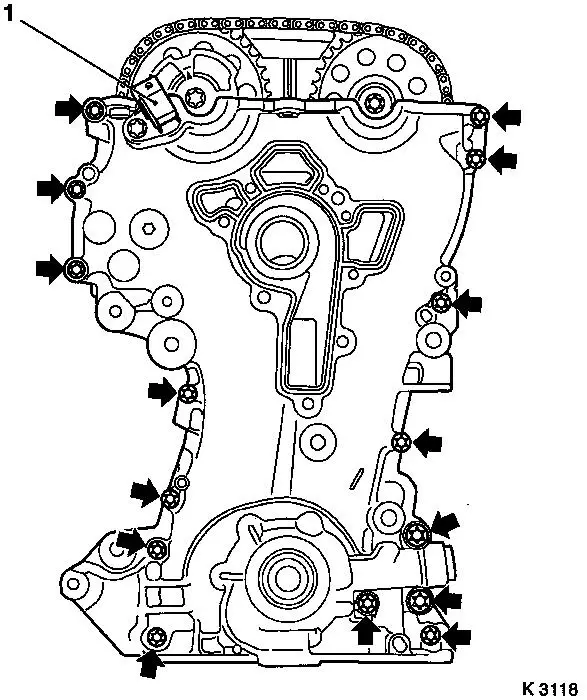

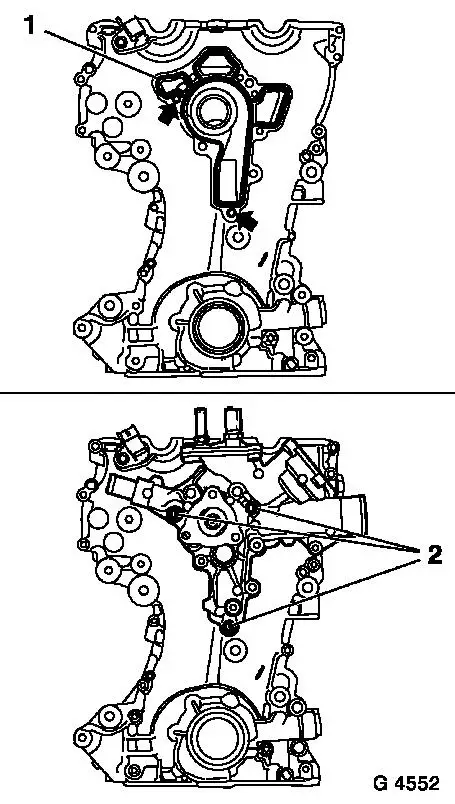

| 25. |

Detach camshaft sensor (1)

|

| 26. |

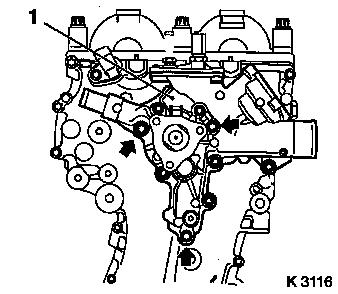

Remove timing case

| • |

Unscrew 15 bolts (arrows)

| – |

Pay attention to bolt lengths

|

|

| • |

Lever out timing case seal ring

Note: Do not damage

sealing surface

|

|

|

|

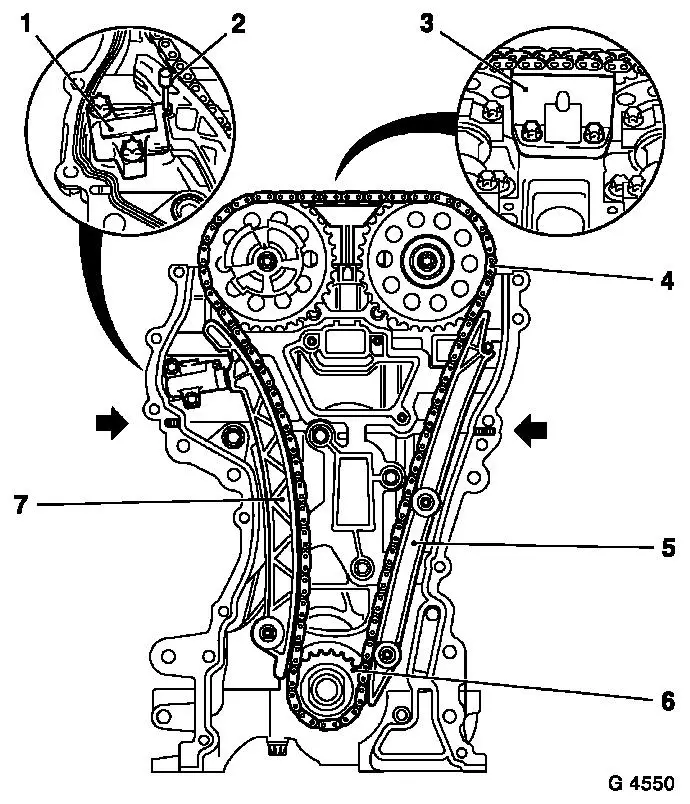

| 27. |

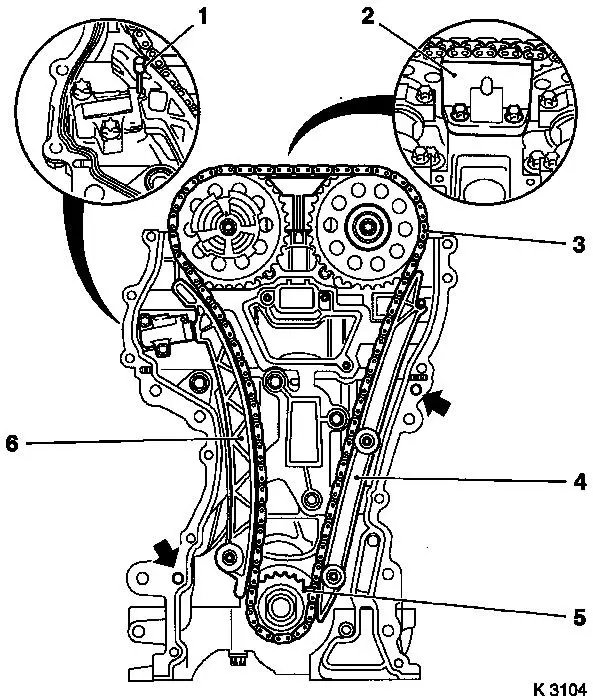

Remove chain drive

| • |

Loosen camshaft sprocket bolts

| – |

Counterhold camshafts at hexagonal section

|

|

| • |

Detach sliding rail (3), guide rail (5), tension rail (7) and

camshaft sprockets

|

| • |

Remove timing chain (4) with drive sprocket (6)

|

| • |

Remove timing case gasket.

|

|

|

|

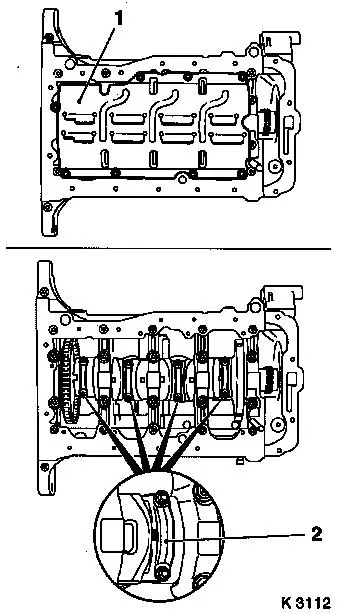

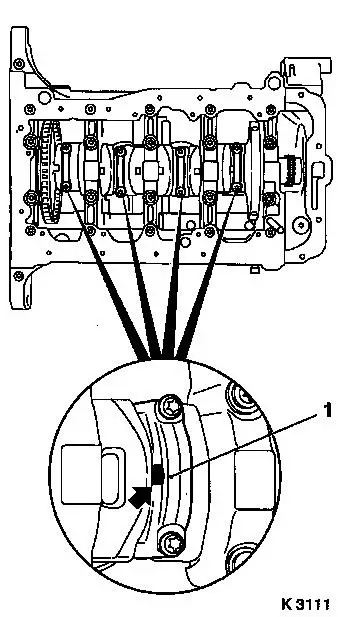

| 28. |

If present: detach oil baffle plate (1)

|

| 29. |

Remove crankshaft sensor

|

| 30. |

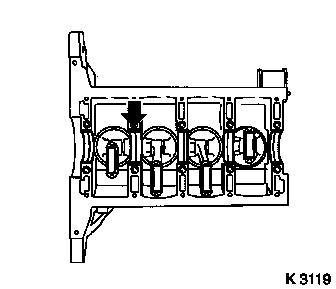

Remove con-rod bearing cap

| • |

Mark 4 con-rod bearing caps (2)

Note: Observe cylinder

sequence

|

Important: The mating surfaces of

the cod-rods and con-rod bearing caps form an individual fit and

must not be damaged or interchanged. Do not lay on mating

surfaces.

|

| • |

Remove 4 con-rod bearing caps

|

|

|

|

| 31. |

Remove crankshaft

| • |

Remove crankshaft bearing bridge

Note: Prise off

evenly

|

| • |

Remove crankshaft rear seal ring

|

| • |

Place crankshaft on wooden blocks

|

|

| 32. |

Remove crankshaft bearing shells

|

| 33. |

Remove crankshaft bearing shells

Note: Observe order

| • |

Mark crankshaft bearing shells

|

|

| 34. |

Remove con-rod bearing shells

Note: Observe order

| • |

Mark con-rod bearing shells

|

|

| 35. |

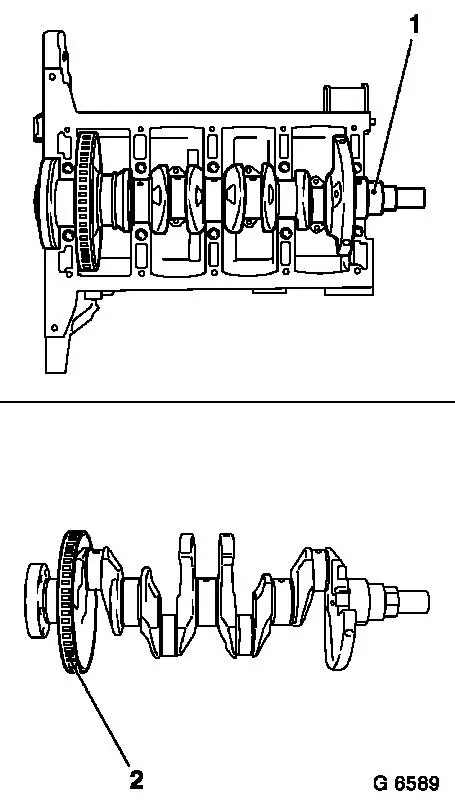

Remove crankshaft pulse pickup disc (1)

|

|

|

| 36. |

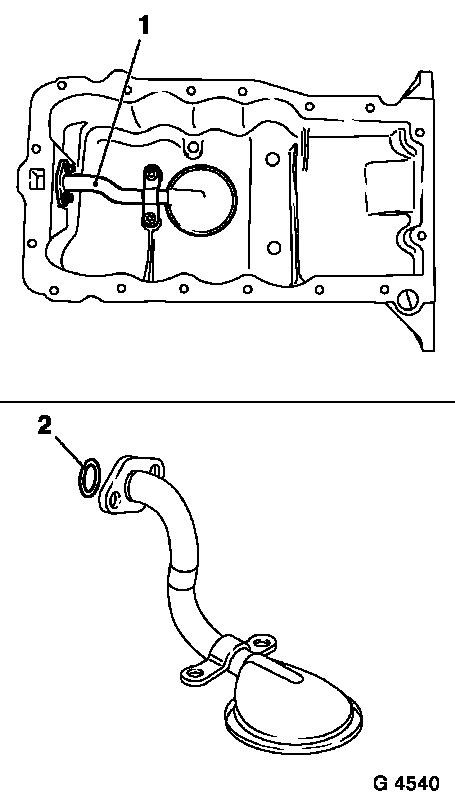

Remove oil intake pipe (1)

|

|

|

Install

Install

| 37. |

Clean sealing surfaces

| • |

Cylinder block, cylinder head, cylinder head cover, crankshaft

bearing bridge, chain drive, timing case, oil pan, coolant pump,

exhaust manifold

|

|

| 38. |

Inspect components

| • |

Cylinder block, cylinder head, cylinder head cover, crankshaft

bearing bridge, chain drive, timing case, oil pan, coolant pump

|

|

| 39. |

Check whether crankshaft bearing bridge is level using a

straightedge and a feeler gauge

|

| 40. |

Attach crankshaft pulse pick-up disk

|

| 41. |

Insert con-rod bearing shells

| • |

In con-rod, con-rod bearing cap

|

|

| 42. |

Insert crankshaft bearing shells

Note: Pay attention to

position of axial bearing (arrow)

| • |

Insert crankshaft bearing bridge into cylinder block

|

|

| 43. |

Insert crankshaft

| • |

Coat crankshaft journal with engine oil

|

|

|

|

| 44. |

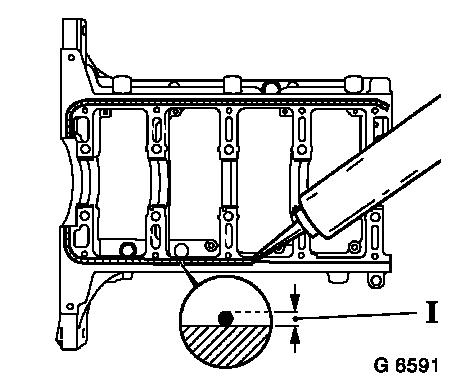

Install crankshaft bearing bridge

Note: Complete

installation work within 10 minutes

| • |

Apply sealant to outer edge of groove (dimension I = 2 mm)

Note: Do not apply

sealant in groove

|

| • |

Tighten 10 bolts (M8) 25 Nm +

60°

|

| • |

Tighten 12 bolts (M6) 10 Nm +

60°

|

|

|

|

| 45. |

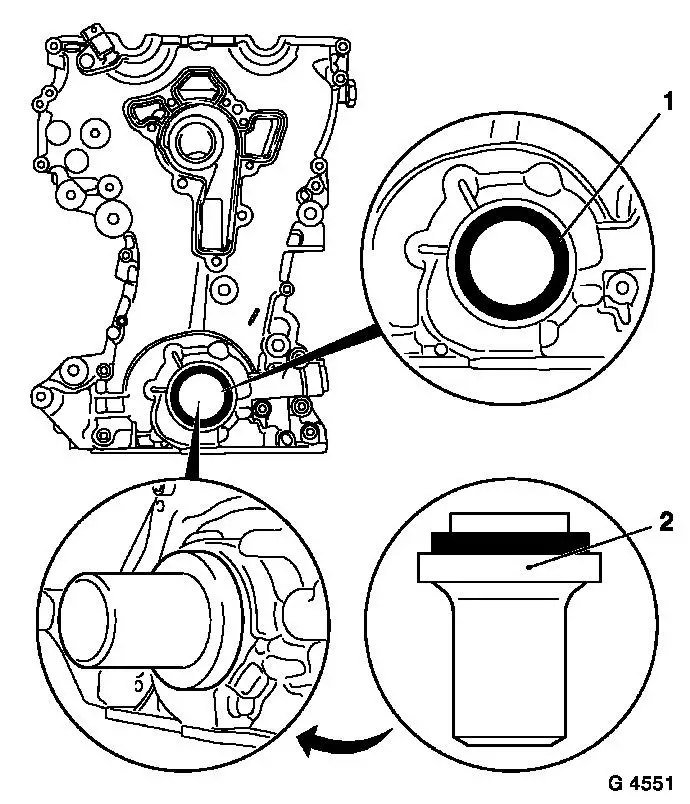

Install rear crankshaft seal ring (1)

| • |

Coat sealing lip with silicone grease

|

| • |

Position KM-235-6 (2) on crankshaft

journal

|

| • |

Slide seal ring onto KM-235-6

|

| • |

Drive in until flush using KM-658-1

(3)

|

|

|

|

| 46. |

Attach con-rod bearing cap

Note: Bead on con-rod

bearing cap faces transmission side

| • |

Tighten 8 bolts (M6) 10 Nm + 60° +

15°

| – |

From engine number 19P13554 ( 13 Nm +

60° + 15° ) (M6.5)

|

|

|

|

|

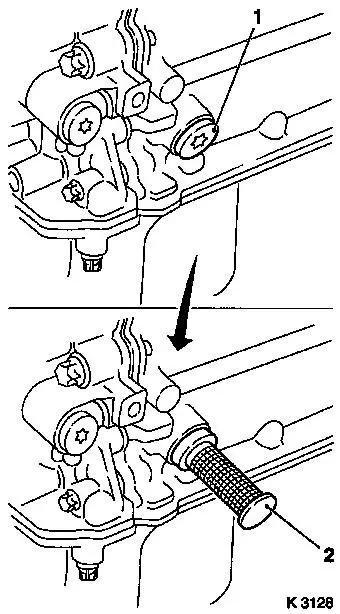

| 47. |

Lock crankshaft

| • |

Remove closure bolt (1)

|

| • |

Insert KM-952 (2)

| – |

Turn crankshaft uniformly until KM-952 engages

|

|

|

|

|

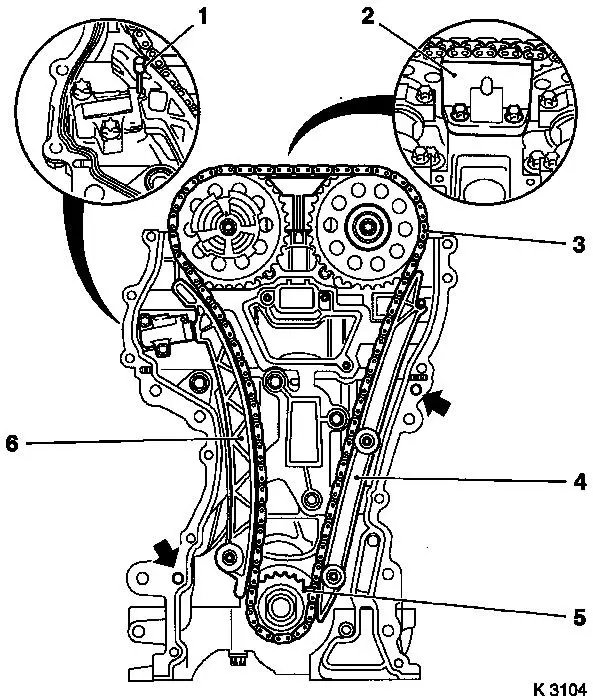

| 48. |

Replace timing case gasket

Note: Complete assembly

operations within 10 minutes

| • |

Apply sealant

| – |

Cut off excess elastomer of cylinder head gasket (1) and

replace with a 2 mm thick bead of silicone sealant

Note: If no excess

elastomer is present, the bead of silicone sealant can be applied

directly

|

| – |

Apply silicone sealant to joint between cylinder block and

crankshaft bearing bridge

|

|

|

|

|

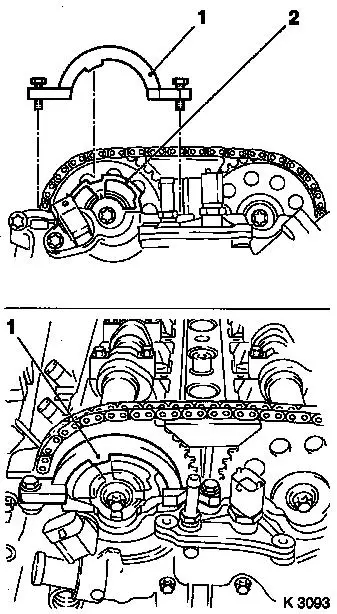

| 49. |

Attach timing chain

Note: Ensure that guide

sleeves are correctly seated (arrows)

| • |

Position exhaust camshaft

|

| • |

Install timing chain (3)

|

| • |

Insert intake camshaft sprocket with phase sensor disc in

timing chain

| – |

Bolt in bolt

Note: It must be

possible to rotate phase sensor disk by hand

|

|

|

|

|

| 50. |

Attach timing chain tension rail (6)

Note: Ensure that

timing chain is correctly seated

|

| 51. |

Attach timing chain guide rail (4)

Note: Ensure that

timing chain is correctly seated

|

| 52. |

Attach timing chain sliding rail (2)

|

| 53. |

Release chain tensioner

|

|

|

| 54. |

Attach coolant pump

Note: Ensure that guide

sleeves are correctly seated (arrows)

| • |

Attach using short bolts (2)

|

| • |

Remove thermostat housing cover

|

|

|

|

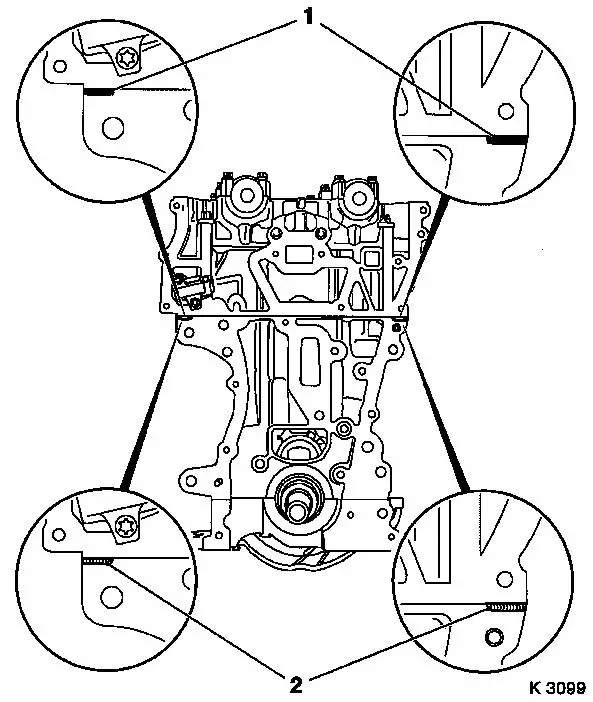

| 55. |

Attach timing case.

| • |

Tighten 5 bolts (1) (M6) 8 Nm

|

| • |

Tighten 14 bolts (2) (M6) 8 Nm

|

| • |

Tighten 2 bolts (3) (M10) 35 Nm

|

| • |

Attach thermostat housing cover

|

|

|

|

| 56. |

Replace crankshaft front seal ring (1)

| • |

Coat sealing lips with silicon grease

|

| • |

Drive in until flush using KM-960

|

|

| 57. |

Remove KM-952

Note: Retaining tools

must not be used for counterholding

|

|

|

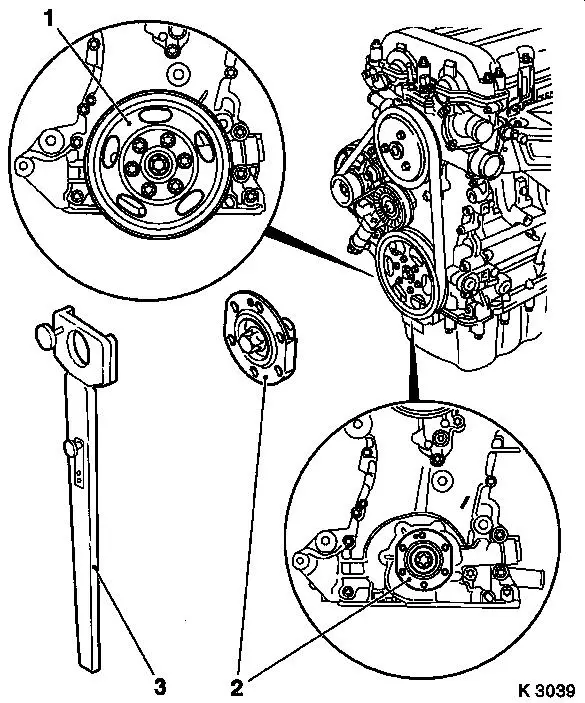

| 58. |

Attach crankshaft hub

Note: Note crankshaft

hub (2) installation position - mark must point upwards

| • |

Counterhold with holder KM-956-1

KM-956-2 (3)

Note: Second person

required

|

| • |

Tighten bolt 150 Nm + 45°

|

| • |

Detach KM-956-1 KM-956-2

|

|

| 59. |

Attach crankshaft ribbed V-belt pulley (1)

| • |

Counterhold at crankshaft hub bolt

|

|

|

|

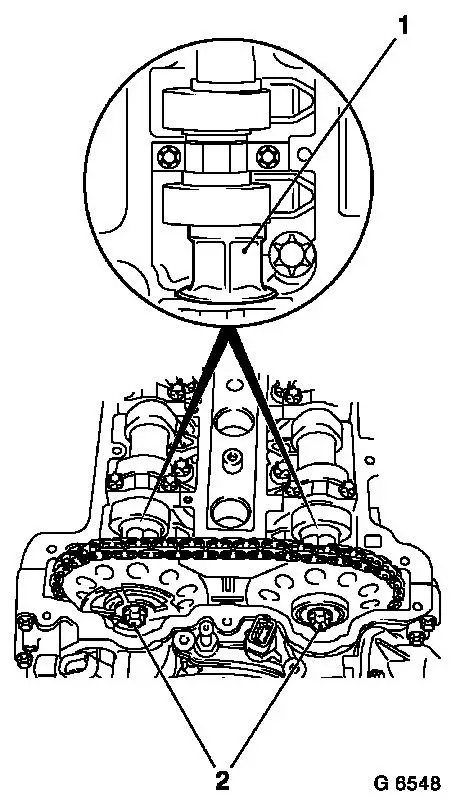

| 61. |

Attach KM-954 (1)

| • |

Rotate phase sensor disk (2) until KM-954 can be attached to timing case

|

|

|

|

| 62. |

Fasten camshaft sprockets

Note: Tightening torque

of 10 Nm is used to secure the camshaft sprockets and the phase

sensor disk

| • |

Tighten 2 bolts (2) 10 Nm

Note: First tighten

intake camshaft sprocket bolt

| – |

Counterhold camshafts at hexagonal section (1)

|

|

|

| 63. |

Remove retaining tools

| • |

KM-952 , KM-953 , KM-954

|

|

| 64. |

Fasten camshaft sprockets

Note: Second person

required

| • |

Tighten 2 bolts 50 Nm + 60°

Note: First tighten

intake camshaft sprocket bolt

| – |

Counterhold camshafts at hexagonal section

|

|

|

|

|

| 66. |

Remove retaining tools

| • |

KM-952 , KM-953 , KM-954

|

|

| 67. |

If present: attach oil baffle plate

|

| 68. |

Attach oil pan

| • |

Align oil pan to cylinder block using straight edge

|

|

| 69. |

Attach closure bolt of crankshaft bearing bridge

|

| 70. |

Install crankshaft sensor

|

| 71. |

Attach cylinder head cover (1)

Note: Complete assembly

operations within 10 minutes

| • |

Renew gasket (2) and seal rings

|

| • |

Apply sealant (dimension I = 2 mm)

|

| • |

Attach engine vent hose

|

|

| 72. |

Install 4 spark plugs

| • |

Tighten using KM-194-E 25 Nm

|

|

| 73. |

Attach ignition module

| • |

Attach ignition module cover

|

|

|

|

| 74. |

Attach camshaft sensor

|

| 75. |

Attach 3 coolant hoses

|

| 76. |

Install engine management wiring harness

| • |

Connect 5 wiring harness plugs

|

|

| 78. |

Install alternator wiring harness

|

| 79. |

Attach ribbed V-belt tensioner

| • |

Tighten bolt (M8) 20 Nm

|

| • |

Tighten bolt (M10) 55 Nm

|

|

| 80. |

Attach coolant pump ribbed V-belt pulley

|

| 81. |

Install ribbed V-belt

Note: Observe running

direction and installation position

| • |

Release ribbed V-belt tensioner

|

|

| 82. |

Attach right engine bracket

|

| 83. |

Attach flywheel

| • |

Clean threads in crankshaft

|

| • |

Tighten 6 bolts 35 Nm + 30°

| – |

Apply screw locking compound

|

|

|

| 84. |

Attach clutch - see operation "Remove and install thrust plate

and clutch disk" in group "K"

|

| 85. |

Top up engine oil

| • |

Check engine oil level, if necessary correct.

|

|

| 86. |

Detach engine

| • |

Suspend engine on workshop crane

|

| • |

Detach from KM-412

| – |

Undo 8 screw connections

|

|

|

|