|

Remove and refit engine (Z 10 XE, Z 10 XEP, with

air conditioning)

Note: KM-6394 must be used as of model year 04 instead of

KM-6169-1 .

Remove Remove

| 1. |

On vehicles as of model year 04 with ESP - every time the

battery is disconnected, the steering angle sensor loses its basic

setting. It must be recalibrated.

|

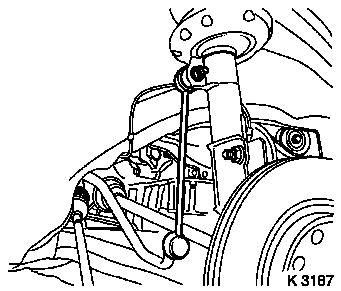

| 4. |

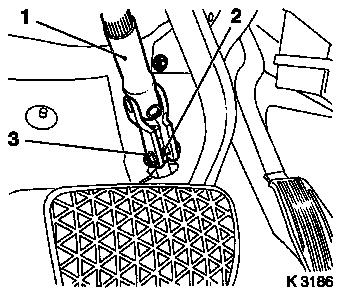

Detach steering intermediate shaft (1)

| • |

Remove lower clamp pin (2)

|

| • |

Steering in straight-ahead position

|

Important: Do not alter steering

wheel position

|

| • |

Remove steering intermediate shaft

|

|

|

|

| 6. |

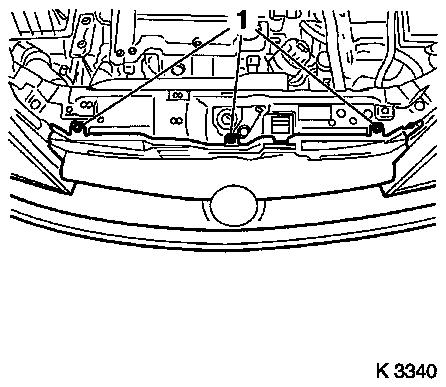

Undo upper front panelling

|

|

|

| 8. |

Undo lower front panelling

|

| 9. |

Detach front panelling

Note: Second person

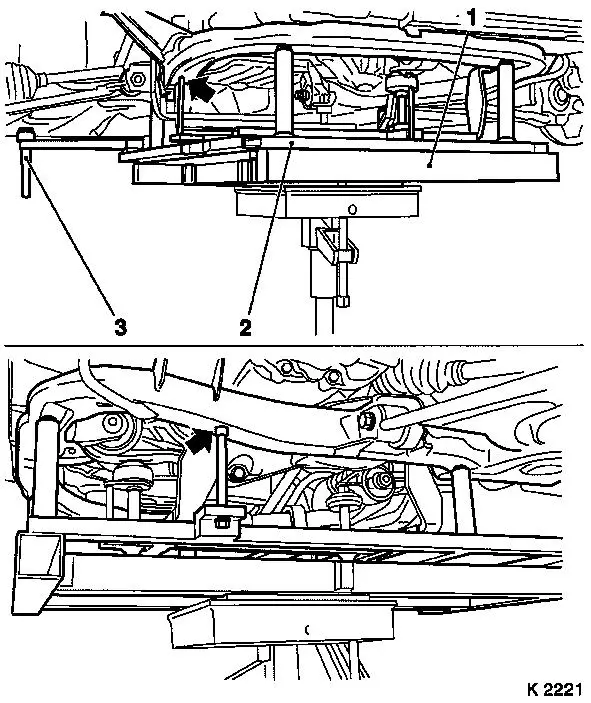

required

| • |

Disconnect temperature sensor wiring harness plug

|

|

|

|

| 11. |

Remove ribbed V-belt cover

Note: In "ECO" model

variant remove lower engine compartment cover, see operation

"J481500 Removing and installing lower engine compartment cover

(ECO)" in group "A"

|

|

|

| 12. |

Drain coolant

| • |

Place collecting basin underneath.

|

| • |

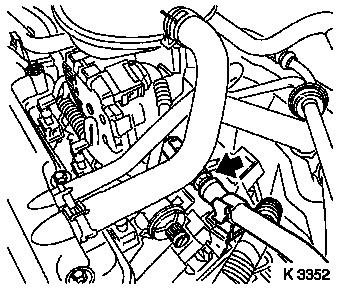

Open drain bolt (arrow)

|

|

|

|

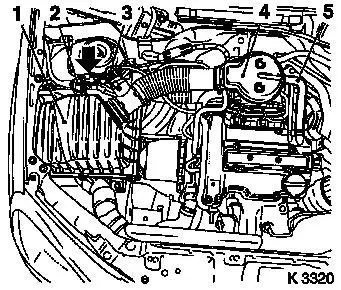

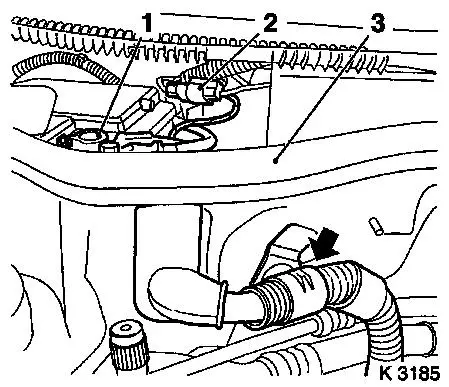

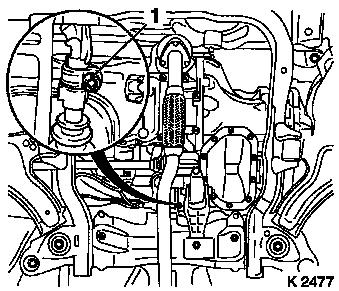

| 13. |

Remove air cleaner housing (1)

| • |

Disconnect 2 wiring harness plugs

| – |

Hot film mass air flow sensor (3), tank vent valve (2)

|

|

| • |

Remove suction pipe (4)

| – |

Detach engine vent hose (5)

|

|

| • |

On Z 10 XEP: Remove air intake hose

|

|

|

|

| 14. |

Detach 2x heater hoses (1) from heater core

|

|

|

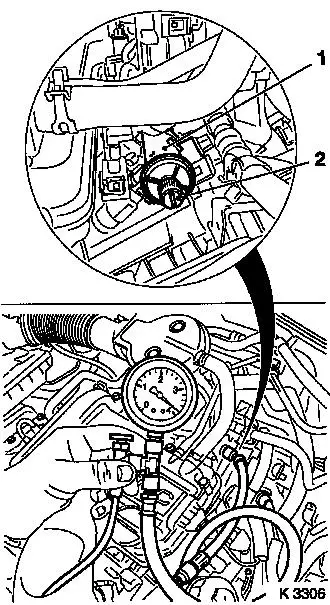

| 15. |

Release fuel pressure with KM-J-34730-91 at fuel rail (1)

Important: Observe safety

precautions and national regulations

|

| • |

Unscrew test connection protective cap (2)

Note: Test connection

for Z 10 XEP at upper fuel rail

|

|

|

|

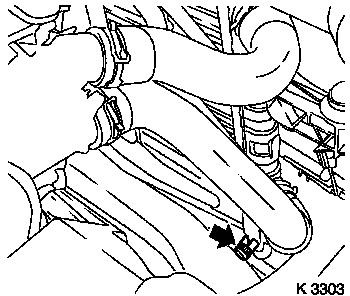

| 16. |

Remove fuel line

| • |

Unclip fuel line (arrow)

|

|

|

|

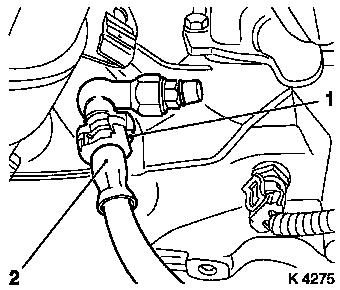

| 17. |

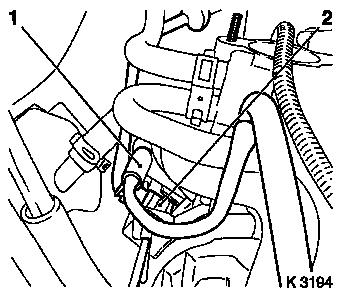

Unclip brake servo vacuum line (2)

|

| 18. |

Detach fuel evaporation hose (1)

|

|

|

| 19. |

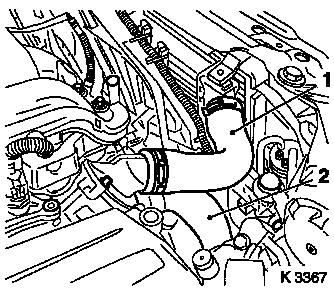

Remove upper radiator hose (1)

|

| 20. |

Remove lower coolant hose (2)

|

|

|

| 21. |

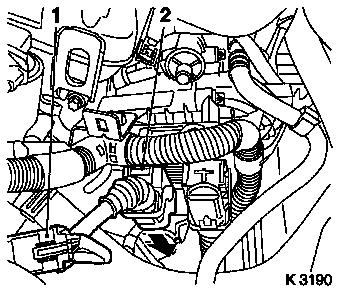

Remove wiring harness for engine management

| • |

Disconnect 2 wiring harness plugs

| – |

Reverse switch, combination plug (1)

|

|

| • |

Disconnect wiring harness plug of engine control unit (2)

| – |

Release in direction of arrow

|

|

| • |

Set wiring harness to one side

|

|

|

|

| 22. |

Disconnect engine wiring harness

| • |

Detach ground cable from battery.

|

| • |

Detach battery positive cable

|

| • |

Remove positive terminal (1)

|

| • |

Disconnect combination plug (2)

|

| • |

Remove cable harness and lay aside

|

|

|

|

| 23. |

Detach clutch actuation pressure hose

| • |

Remove cover of brake fluid reservoir

|

| • |

Top up brake fluid reservoir to "MAX" mark

|

| • |

Disengage retaining clip (1) with a screwdriver

|

| • |

Suspend pressure line for central release

Note: Collect escaping

brake fluid

|

|

| 26. |

Close coolant drain bolt

|

|

|

| 27. |

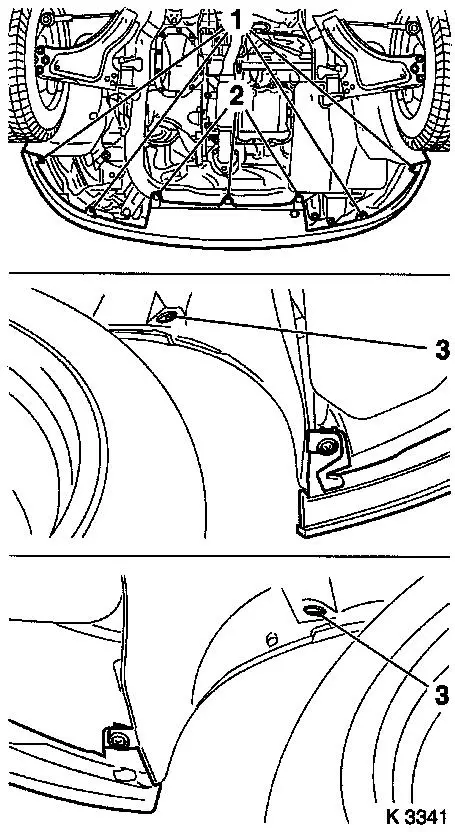

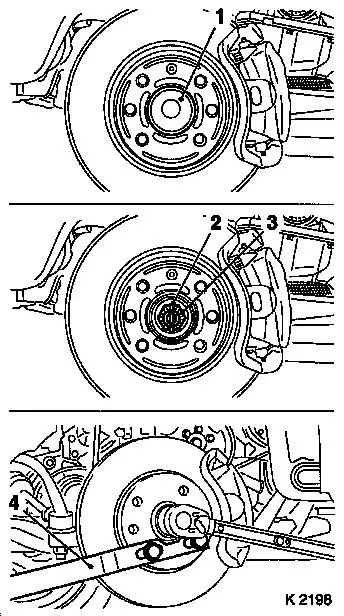

Loosen axle shafts

| • |

Detach 2x protective cap (1)

|

| • |

Remove 2 cotter pins (2)

|

| • |

Unscrew 2x nut (3)

| – |

Counterhold using KM-468-B

|

|

|

|

|

| 28. |

Detach tie rods from steering knuckle

| • |

Push off tie rods with KM-507-C

(1)

|

|

|

|

| 29. |

Detach swing arm from spring strut support tube

| • |

Remove 2 nuts

| – |

Counterhold with open-ended wrench

|

|

|

|

|

| 31. |

Press out axle shafts

|

|

|

| 33. |

Remove ribbed V-belt

| • |

Tension ribbed V-belt tensioner in direction of arrow

|

| • |

From compressor ribbed V-belt pulley

|

|

|

|

| 34. |

Remove compressor

Note: The air

conditioning system remains closed

| • |

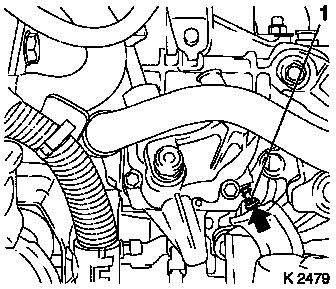

Disconnect wiring harness plug (arrow)

|

| • |

Unscrew 3x bolts (1, 2)

| – |

Remove compressor heat shield

|

|

|

|

|

| 35. |

Remove exhaust system

| • |

Disconnect oxygen sensor (catalytic converter control) wiring

harness plug

|

| • |

Remove front exhaust pipe

|

|

| 36. |

Remove exhaust system

Note: Second person

required

|

|

|

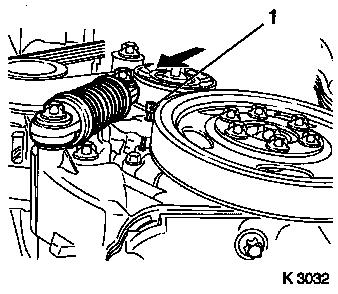

| 39. |

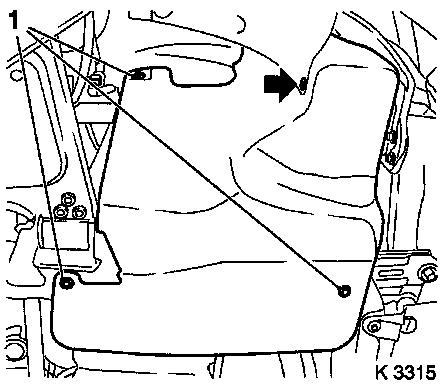

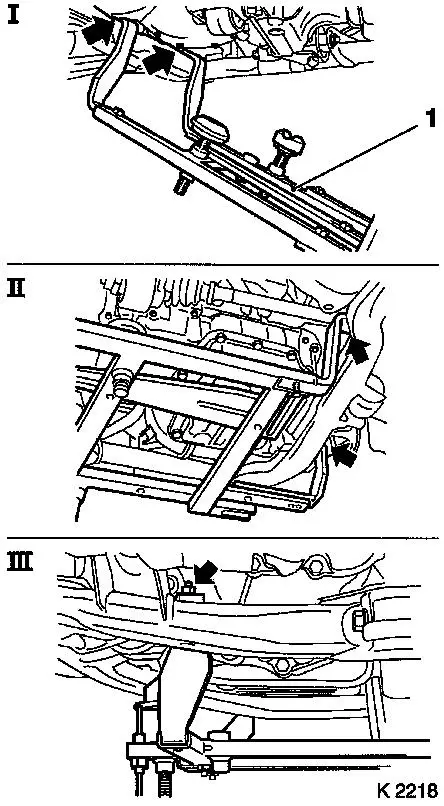

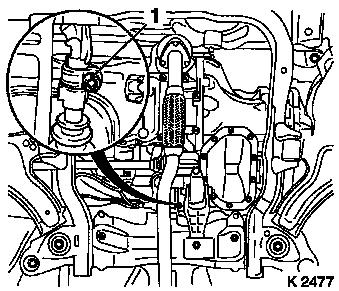

Attach KM-6169 (1)

| • |

Attach KM-6169 to left of front axle

body (arrows, illus. I)

| – |

Guide pin must be seated in bore in front axle body

|

|

| • |

Attach both right holders on the front axle body (arrows,

Illus. II).

| – |

Guide pin must be seated in bore in front axle body (arrow,

Fig. III)

|

|

|

|

|

|

| 40. |

Attach connection to KM-6169

| • |

Adjust bracket (2) for support

|

|

| 41. |

Adjust supports

| • |

Transmission side

| – |

Turn spindles until mounts (3) are positioned at guide journals

free of play

|

|

| • |

Engine timing side

| – |

Insert journal of the support in the bore of the cylinder block

without play (arrow)

|

|

|

|

| 42. |

Remove adapter for right engine bracket

|

| 43. |

Detach left engine damping block adapter

|

|

|

|

| 45. |

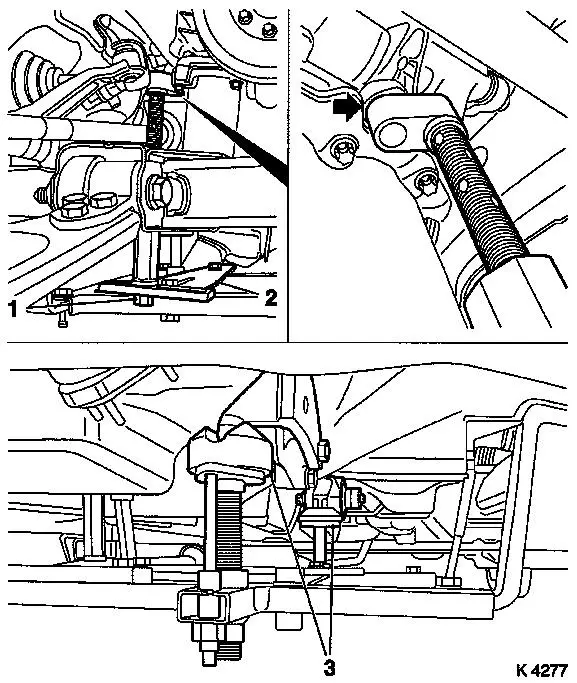

Move in hydraulic jack with KM-904

(1)

|

| 46. |

Attach KM-6168 (2)

| • |

Position KM-6168 on KM-904

Note: Lower body

positioning pins (3)

|

| • |

Position KM-6168 beneath front axle

body without clearance

Note: Note centring

points in front axle body (arrows).

|

|

|

|

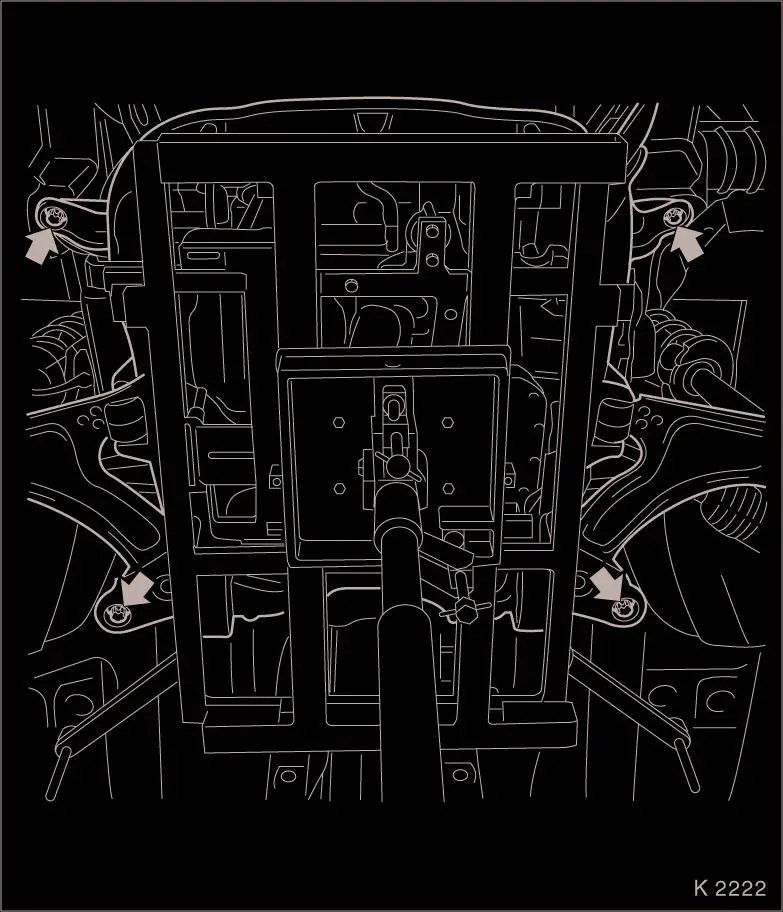

| 47. |

Release front axle body

Note: The removal of

the front axle body with an impulse or impact screwdriver is not

permitted

| • |

Unscrew 4 bolts (arrows)

|

|

| 48. |

Lower drive unit

Note: Second person

required

| • |

Carefully lower front axle body with engine and transmission

out of engine compartment from below

Note: Do not damage

attaching parts

|

|

| 50. |

Check threads of 4x lock nuts

Note: Check ease of

movement of lock nut threads before installing front axle body,

otherwise replace lock nuts

|

|

Install

Install

| 51. |

Install drive unit

Note: Body locating

pins fixed in raised position

|

| 52. |

Raise drive unit

Note: Second person

required

| • |

Carefully move front axle body with engine and transmission

into engine compartment (upwards)

Note: Do not damage

attaching parts

|

| • |

Insert body positioning pins in body positioning holes

|

|

| 53. |

Fasten front axle body

| • |

Tighten 4 bolts 90 Nm + 45° +

15°

|

|

| 54. |

Remove hydraulic jack

|

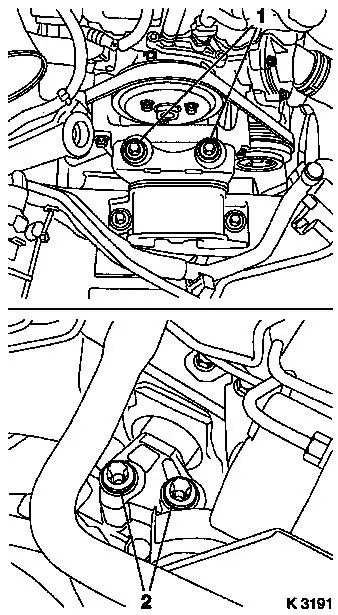

| 56. |

Secure left engine damping block adapter

|

| 57. |

Fasten right engine bracket adapter

| • |

Tighten 2 bolts 60 Nm + 45° +

15°

|

|

| 63. |

Fit compressor

| • |

Connect wiring harness plug

|

|

| 64. |

Install ribbed V-belt

Note: Observe running

direction and installation position

| • |

Relax ribbed V-belt tensioner with KM-6131

|

|

| 66. |

Attach exhaust system

Note: Second person

required

|

| 67. |

Attach exhaust system

| • |

Connect oxygen sensor (catalytic converter control) wiring

harness plug.

|

|

| 71. |

Attach swing arm

| • |

Tighten 2 nuts 65 Nm

| – |

Counterhold with open-ended wrench

|

|

|

| 73. |

Fasten axle shafts

| • |

Tighten 2 nuts 120 Nm

| – |

Counterhold using KM-468-B

|

|

| • |

Tighten 2 nuts 20 Nm + 90°

| – |

Counterhold using KM-468-B

|

|

| • |

Replace split pins

Note: If necessary,

unscrew the nut until a pin hole aligns with the next castle nut

groove

|

| • |

Install protective caps

|

|

| 74. |

Install ribbed V-belt cover

Note: With "ECO" model

variant - install lower engine compartment cover

|

| 75. |

Position front panelling

Note: Second person

required

| • |

Install high-pressure headlamp washer hose

|

|

| 76. |

Fasten lower front panelling

| • |

Connect wiring harness plug

|

|

| 79. |

Fasten upper front panelling

|

| 80. |

Fasten front wheels

| • |

Tighten 8x bolts 110 Nm

|

|

| 81. |

Attach pressure line for central release

Note: Pressure line

must audibly engage

| • |

Bleed clutch actuation – see operation "Hydraulic Clutch

Actuation, Bleed " in group "K".

|

| • |

Screw on cover of brake fluid reservoir

|

|

| 82. |

Connect engine wiring harness

| • |

Connect wiring harness plug

|

| • |

Install positive terminal

|

|

| 83. |

Attach wiring harness for engine management

| • |

Connect 3 wiring harness plugs

|

|

| 84. |

Install lower radiator hose

|

| 85. |

Install upper radiator hose

|

| 86. |

Attach brake servo vacuum line

Note: Connection must

audibly engage

|

| 87. |

Attach fuel evaporation hose

|

| 88. |

Attach fuel line

| • |

Attach fuel line

Note: Fuel line must

audibly engage

|

|

| 89. |

Connect heater fluid hoses

|

| 90. |

Attach preheater hose for throttle valve module

|

| 91. |

Install air cleaner housing

| • |

On Z 10 XEP: Fit air intake hose

|

| • |

Attach engine vent hose

|

| • |

Clip in tank vent valve

|

| • |

Connect 2 wiring harness plugs

|

|

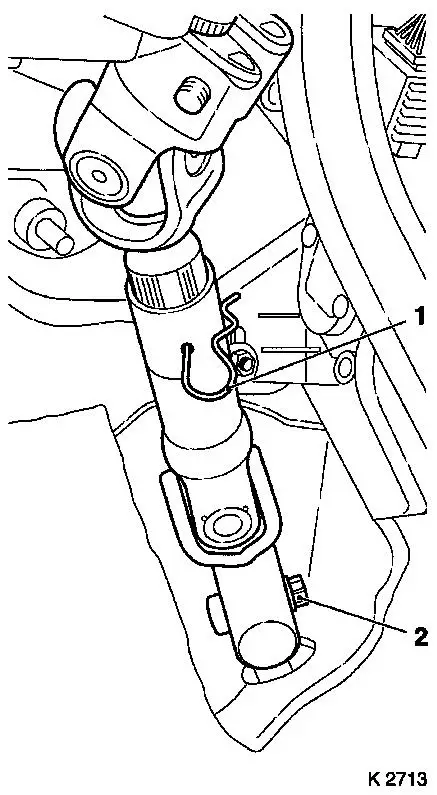

| 92. |

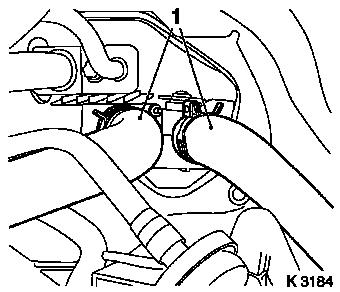

Install steering intermediate shaft

Note: Wheels in

straight-ahead position

| • |

Push on steering intermediate shaft

Note: The bore for the

clamp bolt must be on the flat-milled side of the stub axle

|

| • |

Adjust length compensator

| – |

Fasten with KM-6181 (1)

|

|

|

|

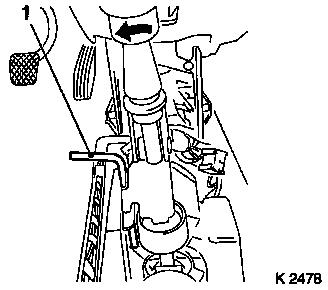

|

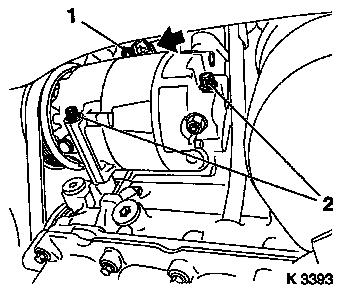

| 93. |

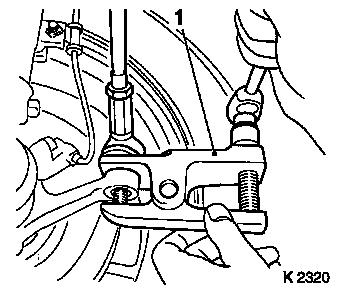

Locking transmission shift linkage

| • |

Unclip manual shift lever cover

|

| • |

Lock shift lever and shift lever housing with KM-527-A (1)

|

|

|

|

| 94. |

Lock transmission

| • |

Engage arresting pint (1) in adjusting bore of shift cover by

twisting the shift rod to the left

|

|

|

|

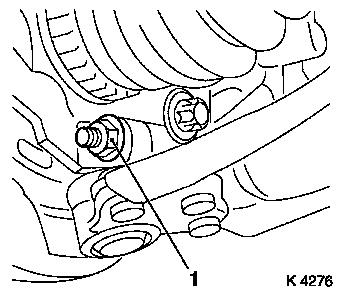

| 96. |

Fasten clamp

| • |

Tighten bolt (1) 12 Nm + 90° +

90° to 90° + 90° +

45°

|

|

|

|

| 98. |

Check transmission shift linkage

| • |

Remove adjusting pin KM-527-A

Note: Locking pin in

adjusting hole releases itself when the first gear selection in

direction "R" occurs

|

| • |

Clip in manual shift lever cover

|

|

| 100. |

Top up and bleed cooling system – see operation "Cooling

System, Top up and Bleed".

|

| 101. |

Program volatile memory

|

|