|

Oil Pump, Remove and Install (Z 18 XE, with Air

Conditioning, LHD)

Note: KM-6394 must be used as of model year 04 instead of

KM-6169-1 .

Remove Remove

| 2. |

Disconnect battery

Note: In vehicles from

model year 04 onwards with ESP - the steering angle sensor loses

its basic adjustment each time the battery is disconnected and must

be recalibrated.

|

| 3. |

Remove engine cover.

| • |

Unscrew oil filler pipe cap

|

| • |

Screw on oil filler pipe cap

|

|

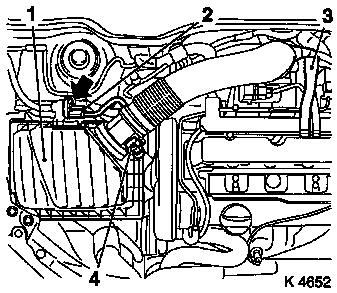

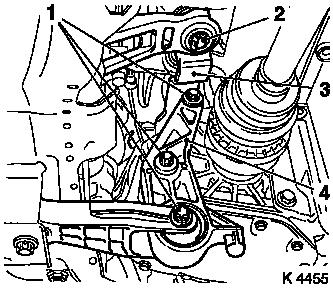

| 4. |

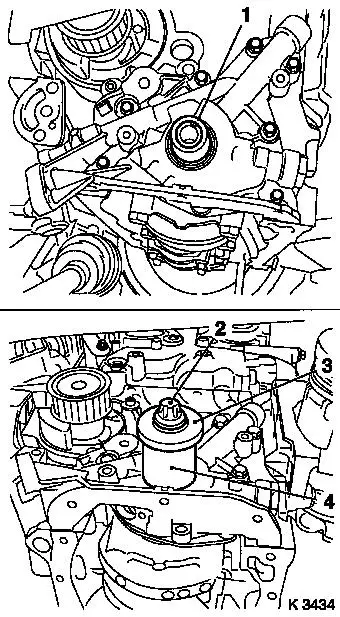

Remove air cleaner housing (1)

| • |

Disconnect 2 wiring harness plugs

| – |

Hot film mass air flow meter (4), tank vent valve (2)

|

|

| • |

Detach engine vent hose (3)

|

|

|

|

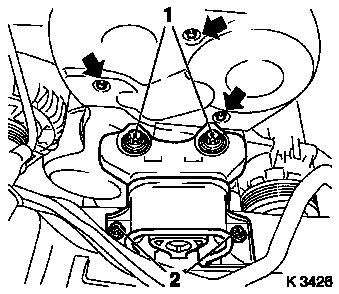

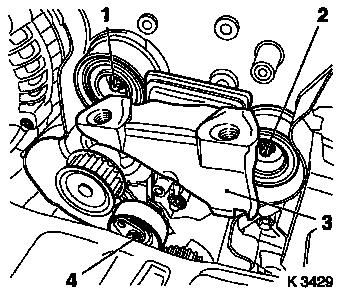

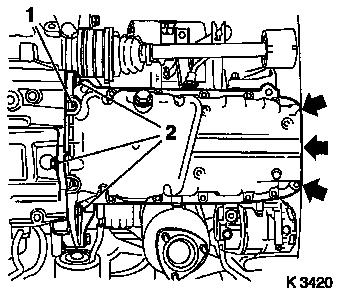

| 6. |

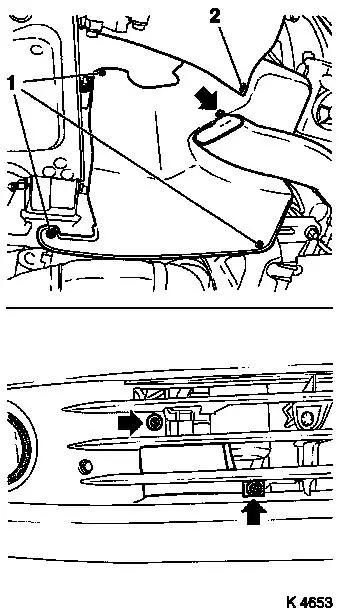

Remove right-hand air duct

| • |

Unscrew 3 bolts (arrows)

|

|

| 7. |

Remove ribbed V-belt cover

|

|

|

| 9. |

Detach front right wheel

|

| 11. |

Remove right front wheel.

|

| 13. |

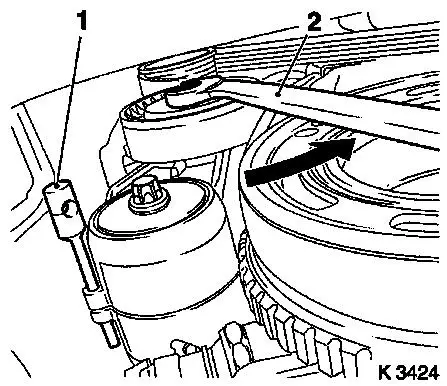

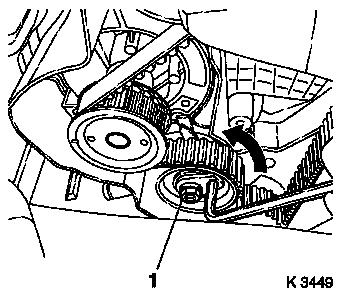

Remove ribbed V-belt

| • |

Tension ribbed V-belt tensioner in direction of arrow with

KM-913-A (2)

|

|

|

|

| 14. |

Remove ribbed V-belt tensioner

| • |

Tension ribbed V-belt tensioner.

|

| • |

Release ribbed V-belt tensioner

|

|

|

|

| 15. |

Detach crankshaft ribbed V-belt pulley

| • |

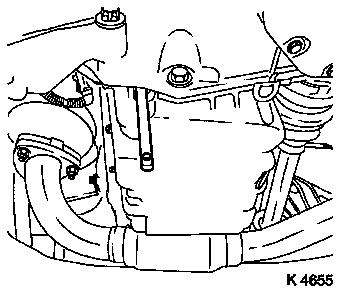

Prise front closure plug out of oil pan

|

|

|

|

| 16. |

Release lower part of toothed belt cover

| • |

Unclip from rear toothed belt cover

|

|

|

|

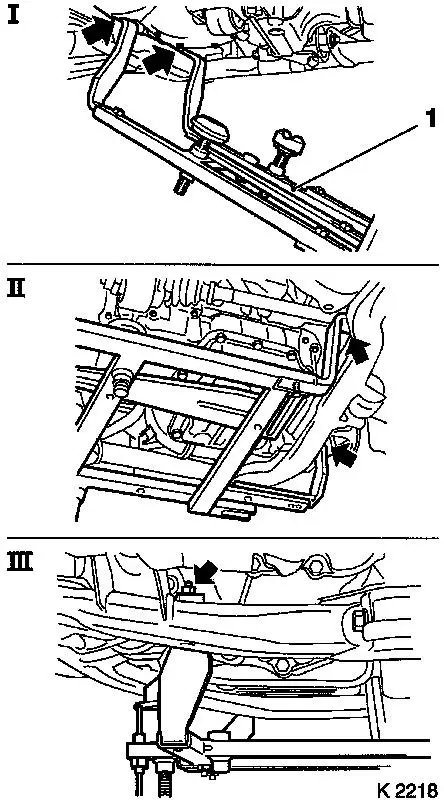

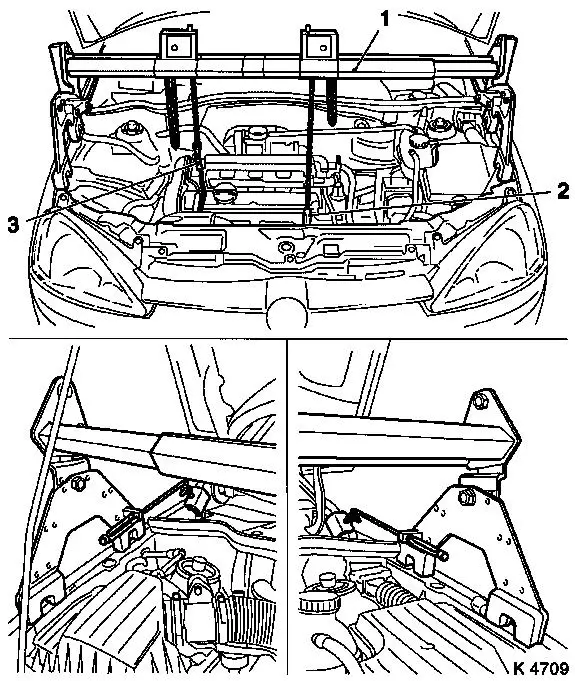

| 18. |

Attach KM-6169 (1)

| • |

Attach KM-6169 to left of front axle

body (arrows, illus. I)

| – |

Guide pin must be seated in bore in front axle body

|

|

| • |

Attach both right holders on the front axle body (arrows,

Illus. II).

| – |

Guide pin must be seated in bore in front axle body (arrow,

Fig. III)

|

|

|

|

|

|

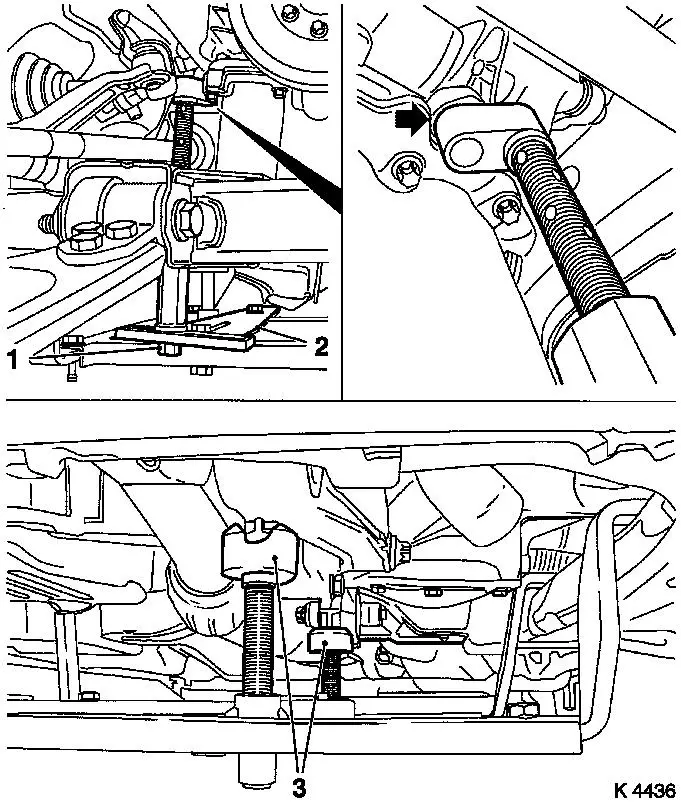

| 19. |

Install support

| • |

An KM-6169

| – |

Adjust bracket (2) for support

|

|

|

| 20. |

Adjust supports

| • |

Transmission side

| – |

Turn spindles until mounts (3) are positioned at guide journals

free of play

|

|

| • |

Engine timing side

| – |

Insert journal of the support in the bore of the cylinder block

without play (arrow)

|

|

|

|

| 22. |

Remove right engine damping block

| • |

Loosen engine bracket adapter

|

| • |

Loosen engine damping block

|

|

| 23. |

Remove upper part of toothed belt cover

| • |

Unscrew 3 bolts (arrows)

|

| • |

Unclip from rear toothed belt cover

|

|

|

|

| 24. |

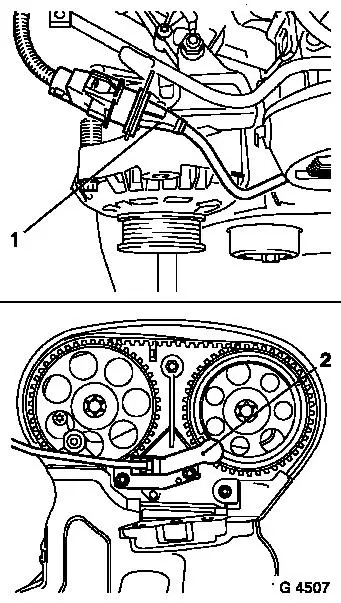

Remove camshaft sensor (2)

| • |

Disconnect wiring harness plug (1)

|

|

| 25. |

Remove lower part of toothed belt cover

| • |

Unclip from rear toothed belt cover

|

|

|

|

|

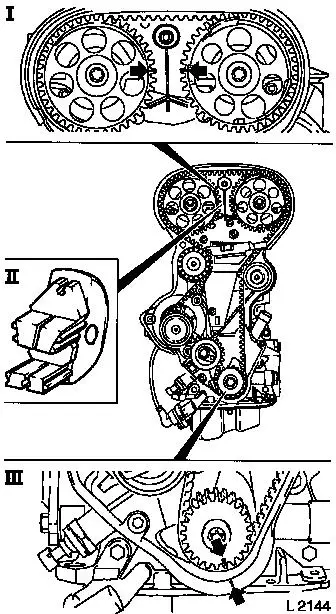

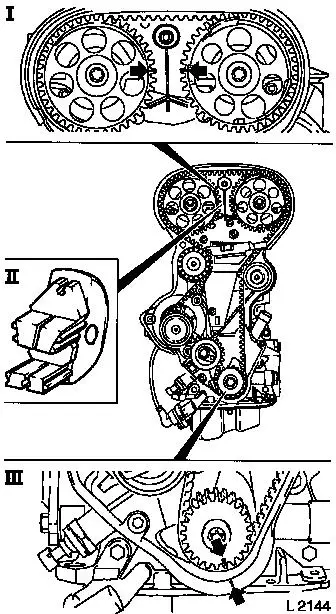

| 26. |

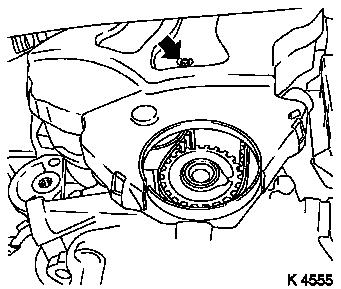

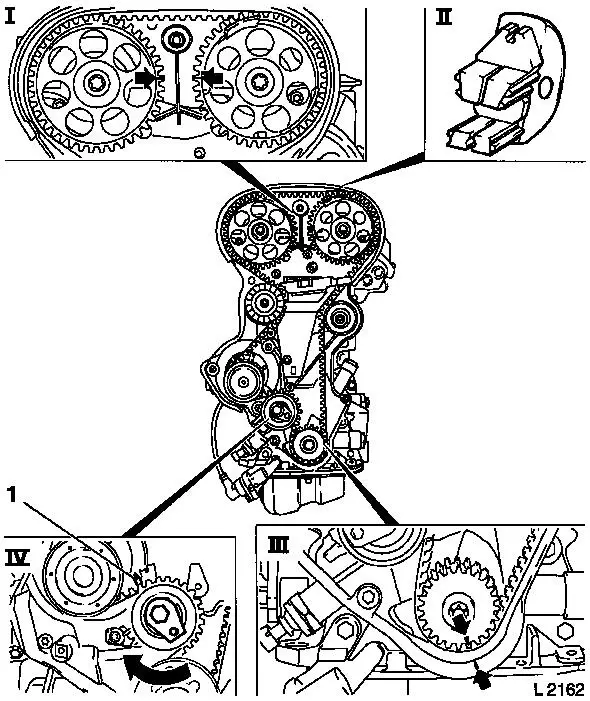

Set 1st cylinder to TDC of combustion stroke

| • |

Install crankshaft V-belt pulley bolt

|

| • |

Set crankshaft to mark.

| – |

Marks on drive gear toothed belt and rear toothed belt cover

must align (III).

|

|

| • |

Fix camshaft sprockets in position.

| – |

Marks must be opposite one another and aligned with the top

edge of the cylinder head (I)

|

|

|

| 27. |

Remove toothed belt

| • |

Release toothed belt tension roller (IV)

| – |

Turn adjusting eccentric in direction of arrow (clockwise)

until pointer (1) of the toothed belt tension roller is located

just before left stop.

|

|

|

|

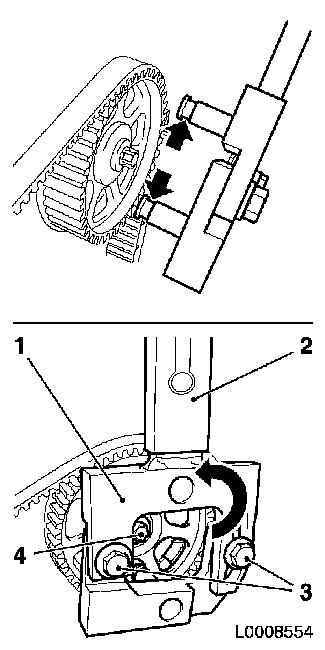

| 28. |

Remove camshaft sprocket on exhaust side

| • |

Use KM-6347 (1), KM-956-1 (2)

|

| • |

Attach KM-6347 , KM-956-1

| – |

Release fixing bolts (3) from KM-6347

|

| – |

Insert KM-6347 together with KM-956-1 into camshaft sprocket

Note: Grooves of KM-6347 must engage in camshaft sprocket

(arrows). Ensure correct seating.

|

|

| • |

Turn KM-6347 together with KM-956-1 in the direction of the arrow

| – |

Tighten 2 clamping screws

|

|

| • |

Loosen camshaft sprocket bolt (4)

|

| • |

Remove KM-6347 , KM-956-1

|

| • |

Unscrew camshaft sprocket bolt

|

|

|

|

| 29. |

Remove camshaft sprocket on intake side

| • |

Use KM-6347 (1), KM-956-1 (2)

|

| • |

Attach KM-6347 , KM-956-1

| – |

Release fixing bolts (3) from KM-6347

|

| – |

Insert KM-6347 together with KM-956-1 into camshaft sprocket

Note: Grooves of KM-6347 must engage in camshaft sprocket

(arrows). Ensure correct seating.

|

|

| • |

Turn KM-6347 together with KM-956-1 in the direction of the arrow

| – |

Tighten 2 clamping screws

|

|

| • |

Loosen camshaft sprocket bolt (4)

|

| • |

Remove KM-6347 , KM-956-1

|

| • |

Unscrew camshaft sprocket bolt

|

|

| 30. |

Remove intake side toothed belt guide roller

|

| 31. |

Remove exhaust side toothed belt guide roller

|

| 32. |

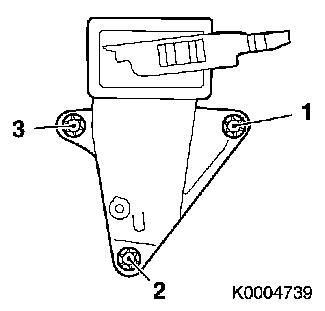

Remove right engine bracket (3)

|

| 33. |

Remove toothed belt tension roller

|

|

|

|

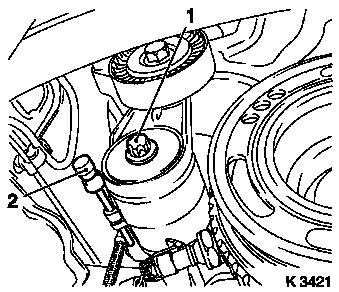

| 34. |

Use MKM-883-1 (1)

Note: Second person

required

|

| 35. |

Fasten MKM-883-1

Note: Observe

manufacturer's instructions

|

| 36. |

Attach engine

| • |

To right engine transport shackle (3)

|

| • |

To front left engine transport shackle (2)

Note: Fastening to

front left engine transport shackle serves only to stabilise the

engine

|

|

|

| 38. |

Remove toothed belt drive pulley

| • |

Unscrew crankshaft ribbed V-belt pulley bolt

|

|

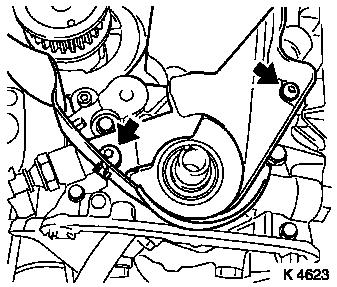

| 39. |

Release rear toothed belt cover

| • |

Unscrew 2 bolts (arrows)

|

|

|

|

| 42. |

Loosen exhaust system

Note: Bends in the flex

pipe with an angle as little as 5 – 10 degrees from the

intended installation position may result in damage with subsequent

total failure of the flex pipe.

| • |

When removing the centre muffler, a catalytic converter, an

exhaust manifold or an exhaust manifold with catalytic converter,

the exhaust system piece remaining in the vehicle must be prevented

from swinging uncontrollably.

Note: The exhaust

system piece with the flex pipe inside can be secured for this

purpose using suitable means, such as a wire on the vehicle

underbody.

|

| • |

Remove wiring harness plug for catalytic converter control

oxygen sensor

|

| • |

Suspend front exhaust pipe from left front axle body

|

|

| 43. |

Remove front reaction member

|

|

|

| 44. |

Release shift guide (3)

| • |

Remove retaining clip (2)

|

|

| 45. |

Release rear reaction member (4)

|

|

|

| 47. |

Remove rear of toothed belt cover

|

| 48. |

Lift engine

Note: Observe

manufacturer's instructions

| • |

Carefully raise the engine approx. 40 mm on the timing side

with MKM-883-1

|

|

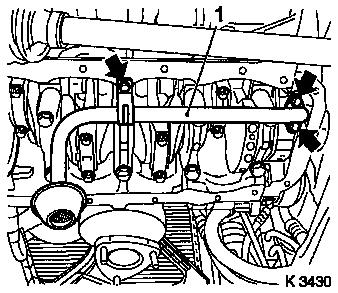

| 50. |

Remove oil pan

| • |

Prise out 2x closure plugs (1)

|

| • |

Oil pump

| – |

Unscrew 3 bolts (arrows)

|

|

|

|

|

| 51. |

Remove oil intake pipe (1)

| • |

Unscrew 3 bolts (arrows)

|

|

|

|

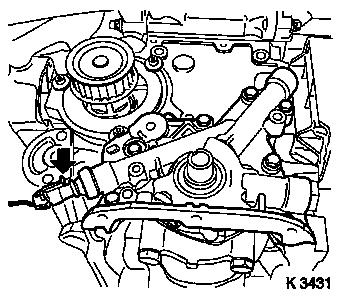

| 52. |

Remove oil pump

| • |

Disconnect oil pressure switch wiring harness plug (arrow)

|

|

| 53. |

Remove crankshaft front seal ring

| • |

Lever out seal ring

Note: Do not damage

sealing surface

|

|

|

|

Install

Install

| 54. |

Clean sealing surfaces

| • |

Oil pump, cylinder block, oil pan, oil suction pipe, cylinder

head, cylinder head cover

|

|

| 55. |

Inspect components

| • |

Ribbed V-belt, ribbed V-belt tensioner, ribbed V-belt pulley,

toothed belt drive, camshafts, oil pump, oil suction pipe

|

|

| 57. |

Install oil pump

| • |

Insert bolts with locking compound

|

| • |

Connect oil pressure switch wiring harness plug

|

|

| 58. |

Install crankshaft front seal ring

| • |

Coat seal lip with grease

|

| • |

Attach KM-6010 to crankshaft journal

(1)

|

| • |

Slide seal ring over KM-6010

|

| • |

Pull in crankshaft front seal ring with KM-6010 (4), bolt (2) and crankshaft ribbed V-belt

pulley washer (3)

|

|

| 59. |

Install oil intake pipe

| • |

Insert bolts with locking compound

|

|

|

|

| 60. |

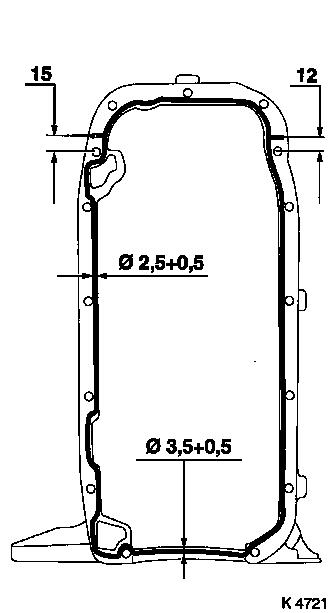

Install oil pan

| • |

Apply sealant

| – |

Complete assembly operations within 10 minutes

|

|

| • |

Screw in bolts

Note: Note tightening

sequence.

|

| • |

At cylinder block

| – |

Tighten 12x bolts 10 Nm

|

|

| • |

Insert 2x closure plugs

|

|

| 62. |

Lower engine

Note: When lowering pay

attention to the shift guide and rear reaction member

|

| 64. |

Fasten rear reaction member

|

| 65. |

Install front reaction member

| • |

Tighten bolted connection 60 Nm

|

|

|

|

| 66. |

Attach KM-6169

| • |

Position KM-6169 on left on front axle body

| – |

Guide pin must be seated in bore in front axle body

|

|

| • |

Attach both right holders on the front axle body

| – |

Guide pin must be seated in bore in front axle body

|

|

|

| 67. |

Install support

| • |

An KM-6169

| – |

Adjust mount for support

|

|

|

| 68. |

Adjust supports

| • |

Transmission side

| – |

Turn spindles until mounts are positioned at guide journals

free of play

|

|

| • |

Engine timing side

| – |

Insert journal of the support in the bore of the cylinder block

free of play

|

|

|

| 69. |

Attach exhaust system

| • |

Connect oxygen sensor (catalytic converter control) cable

harness plug.

|

|

| 70. |

Install rear toothed belt cover

|

| 71. |

Install toothed belt drive gear

| • |

Install crankshaft V-belt pulley bolt

|

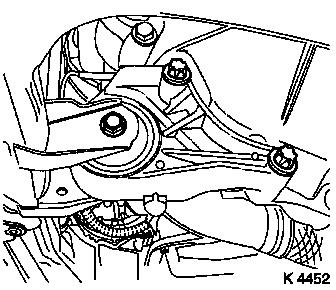

|

| 72. |

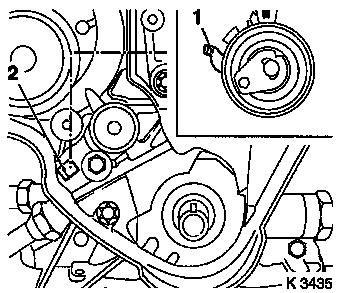

Install toothed belt tension roller

| • |

Detent lever (1) of toothed belt tension roller must engage in

guide web (2) of oil pump.

|

| • |

Bolt in bolt

Note: Adjust toothed

belt tension before tightening bolt.

|

|

|

|

| 73. |

Install right engine bracket

| • |

Insert bolts with locking compound (red)

|

| • |

Tighten 3x bolts 65 Nm + 45° -

60°

|

|

|

|

| 74. |

Install intake side toothed belt guide roller

Note: The toothed belt

guide roller with the greater diameter is installed at the intake

side.

|

| 75. |

Install exhaust side toothed belt guide roller

|

| 76. |

Install camshaft sprocket on exhaust side

Note: Attach camshaft

sprocket with cylinder recognition to exhaust camshaft.

| • |

Attach KM-6347 , KM-956-1

|

| • |

Tighten bolt 50 Nm + 60° +

15°

Note: 2nd fitter

required

|

| • |

Remove KM-6347 , KM-956-1

|

|

| 77. |

Install camshaft sprocket on the intake side

Note: Attach camshaft

sprocket with cylinder recognition to exhaust camshaft.

| • |

Attach KM-6347 , KM-956-1

|

| • |

Tighten bolt 50 Nm + 60° +

15°

Note: 2nd fitter

required

|

| • |

Remove KM-6347 , KM-956-1

|

|

| 78. |

Fix camshaft sprockets in position.

| • |

Marks must be opposite one another and aligned with the top

edge of the cylinder head (I)

|

| • |

Use KM-852 (II)

| – |

Turn the camshafts at hexagonal section

|

|

|

| 79. |

Lock crankshaft

| • |

Set crankshaft to mark.

| – |

Marks on drive gear toothed belt and rear toothed belt cover

must align (III).

|

|

|

|

|

| 80. |

Inspect components

| • |

Ribbed V-belt, ribbed V-belt tensioner, ribbed V-belt pulleys,

toothed belt drive

|

|

| 81. |

Install toothed belt

Note: Pay attention to

direction of travel and timing marks.

| • |

Position toothed belt

| – |

Tensioned side must be taut.

|

|

|

| 82. |

Tension toothed belt

| • |

Tension toothed belt tension roller

| – |

Turn adjusting eccentric in direction of arrow (anticlockwise)

until pointer of the toothed belt tension roller is located just

before left stop

|

|

| • |

Fasten toothed belt tension roller bolt (1)

|

|

|

|

| 84. |

Timing, Check

| • |

Turn crankshaft in direction of engine rotation at the

crankshaft ribbed V-belt pulley bolt (720°)

|

| • |

Set crankshaft to mark.

| – |

Marks on drive gear toothed belt and rear toothed belt cover

must align (III).

|

|

| • |

Use KM-852 (II)

| – |

Marks must be opposite one another and aligned with the top

edge of the cylinder head (I)

|

|

|

|

|

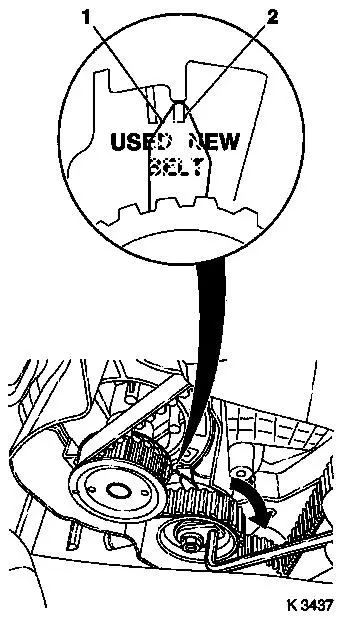

| 86. |

Adjust toothed belt tension

| • |

Release toothed belt tension roller

|

| • |

Turn adjustment eccentric in the direction of the arrow

(clockwise) until pointer (1) of toothed belt tension roller is

aligned with the notch mark NEW (2).

|

| • |

Tighten toothed belt tension roller bolt 20 Nm

|

|

| 87. |

Check toothed belt tension

| • |

Pointer on the toothed belt tension roller and notch mark NEW

must align

|

|

|

|

| 88. |

Install lower part of toothed belt cover

| • |

Clip to rear of toothed belt cover

|

|

| 89. |

Install upper part of toothed belt cover

| • |

Clip to rear toothed belt cover

|

|

| 90. |

Connect camshaft sensor wiring harness plug

| • |

Connect wiring harness plug

|

|

| 91. |

Install right engine damping block

| • |

Fasten engine bracket adapter

| – |

Tighten 2x bolts 60 Nm + 30° -

45°

|

|

| • |

Fasten engine damping block

|

|

| 95. |

Install ribbed V-belt tensioner

| • |

Tension ribbed V-belt tensioner with KM-913-A

|

|

| 96. |

Attach crankshaft ribbed V-belt pulley

| • |

Tighten bolt 95 Nm + 30° +

15°

|

| • |

Insert front closure plug

|

|

| 97. |

Install ribbed V-belt

Note: Observe running

direction and installation position

| • |

Slacken ribbed V-belt tensioner with KM-913-A

|

|

| 98. |

Install ribbed V-belt cover

|

| 99. |

Install right-hand air duct

|

| 101. |

Attach front right wheel

|

| 103. |

Fasten right front wheel.

|

| 104. |

Install air cleaner housing

| • |

Attach engine vent hose

|

| • |

Clip in tank vent valve

|

| • |

Connect 2 wiring harness plugs

|

|

| 105. |

Install engine cover.

| • |

Unscrew oil filler pipe cap

|

| • |

Screw on oil filler pipe cap

|

|

| 107. |

Calibrate steering angle sensor

| • |

Rotate the steering wheel one time from its right-hand to its

left-hand stop

|

|

| 108. |

Program volatile memories

|

|