|

End Shield, Disassemble and Assemble (F 17)

Note: Transmission

remains installed.

Remove Remove

|

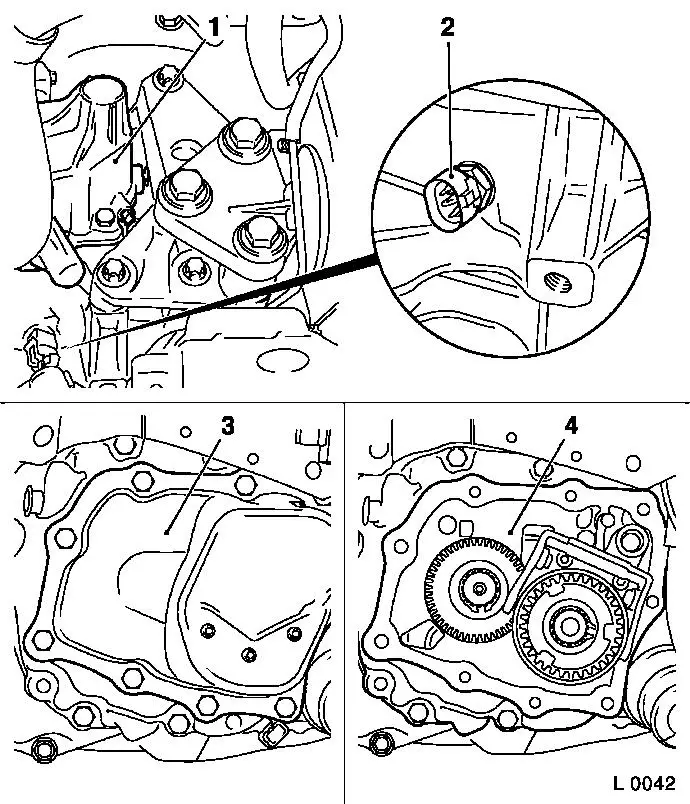

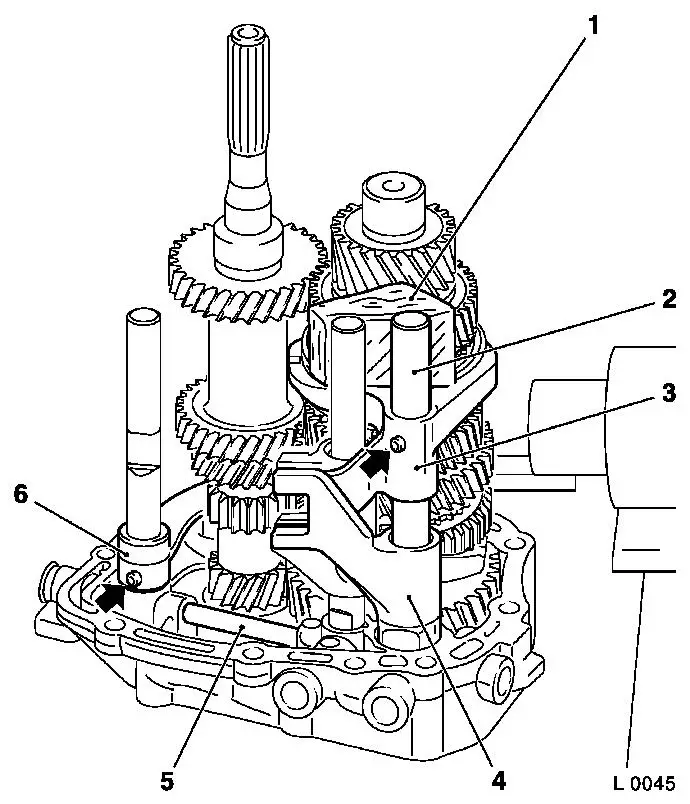

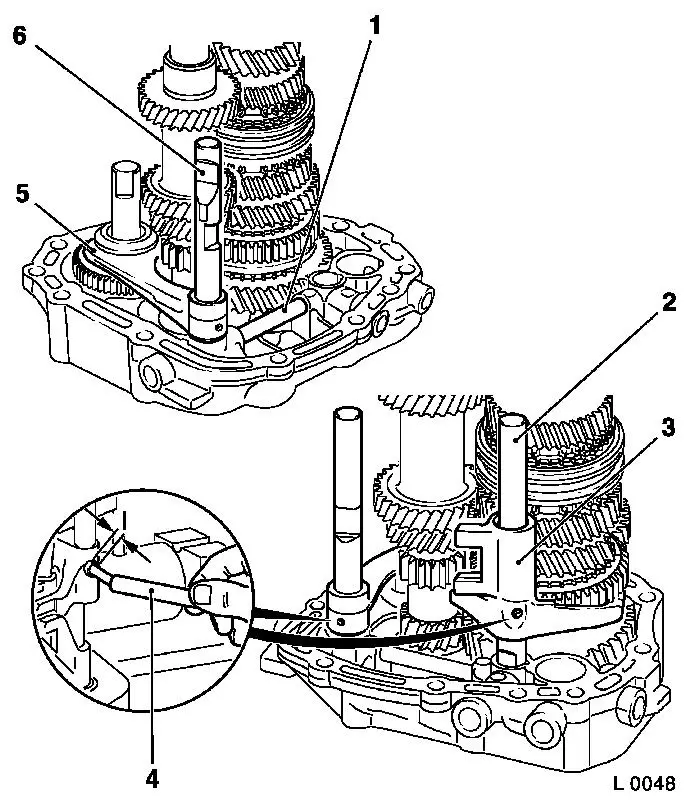

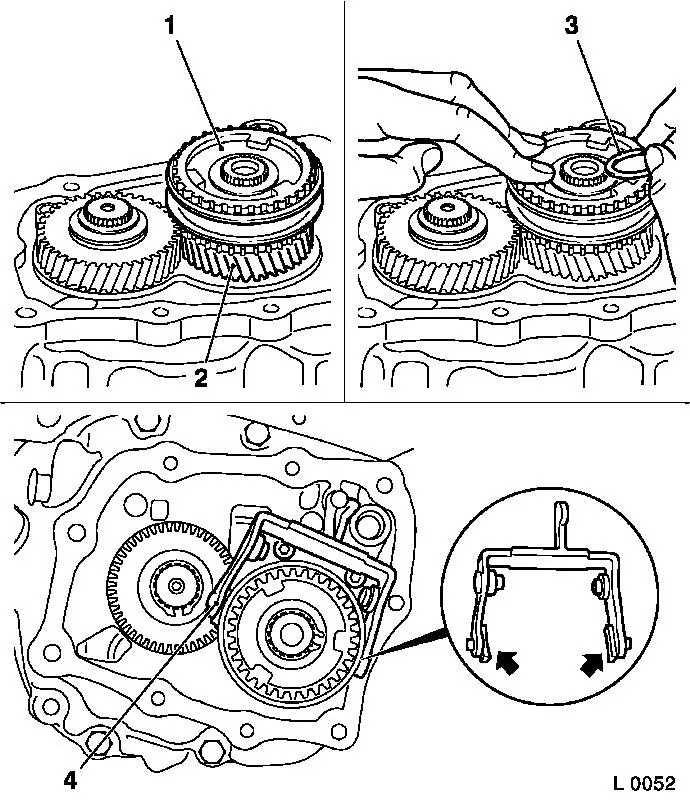

| 1. |

Remove shift mechanism cover (1)

|

| 2. |

Remove reversing lamps switch (2).

|

| 3. |

Remove end shield cover (3)

|

| 4. |

Remove end shield (4) from transmission

|

|

|

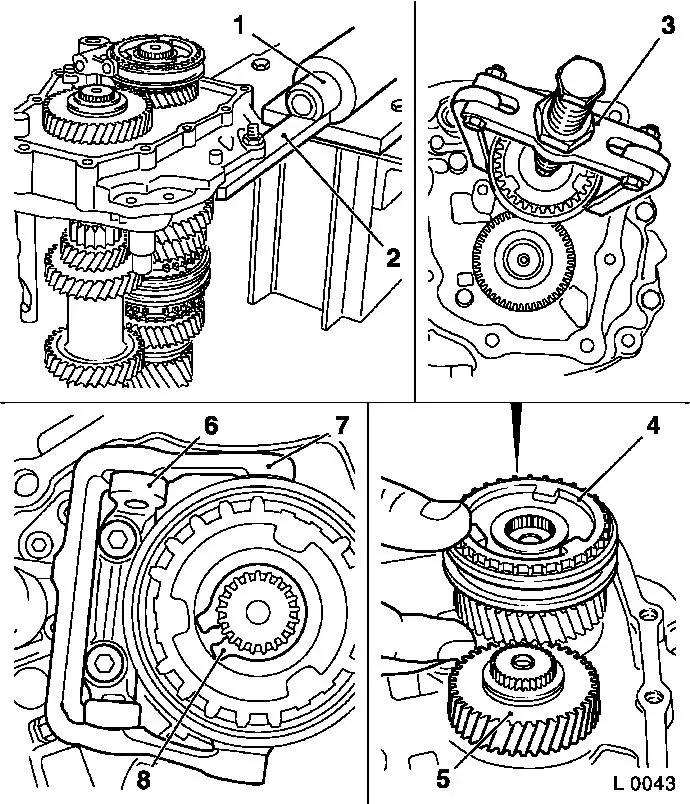

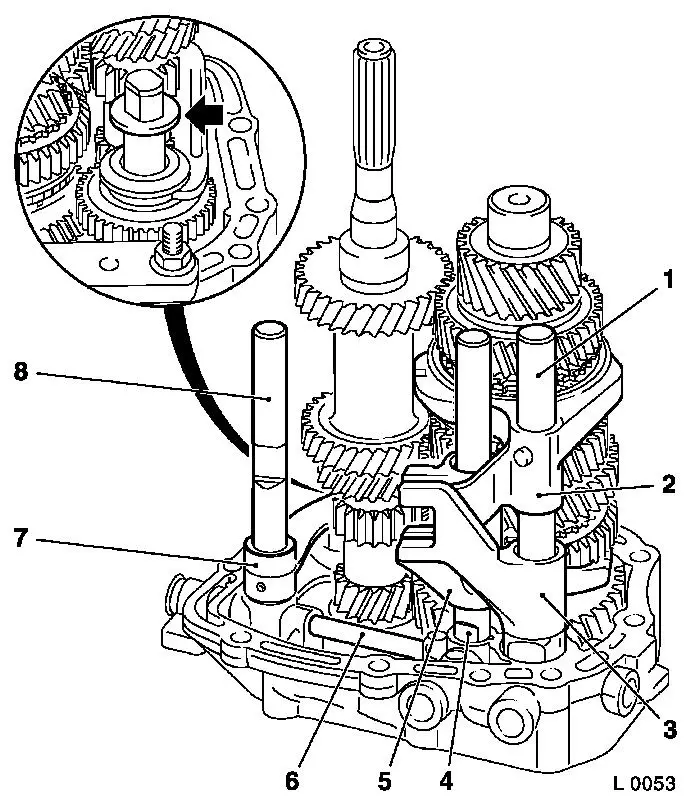

| 5. |

Attach end shield to KM-552 (2)

| • |

Attach KM-552 to KM-113-2 (1)

|

|

| 6. |

Remove bearing block (6) with pivoting lever (7) from end

shield

| • |

Unscrew 2x bolt

Note: Microencapsulated

bolts. If the bolts are difficult to move, heat the end shield to

approx. 80°C with an industrial hot-air blower.

|

|

| 7. |

Remove both needle cages for 5th gearwheel

| • |

Detach retaining ring (8) from synchro body

|

| • |

Remove 5th gear synchro body (4) with 5th gear gearwheel (5)

from main shaft

Note: If it is

difficult to move, use KM-161-B (3).

|

|

|

|

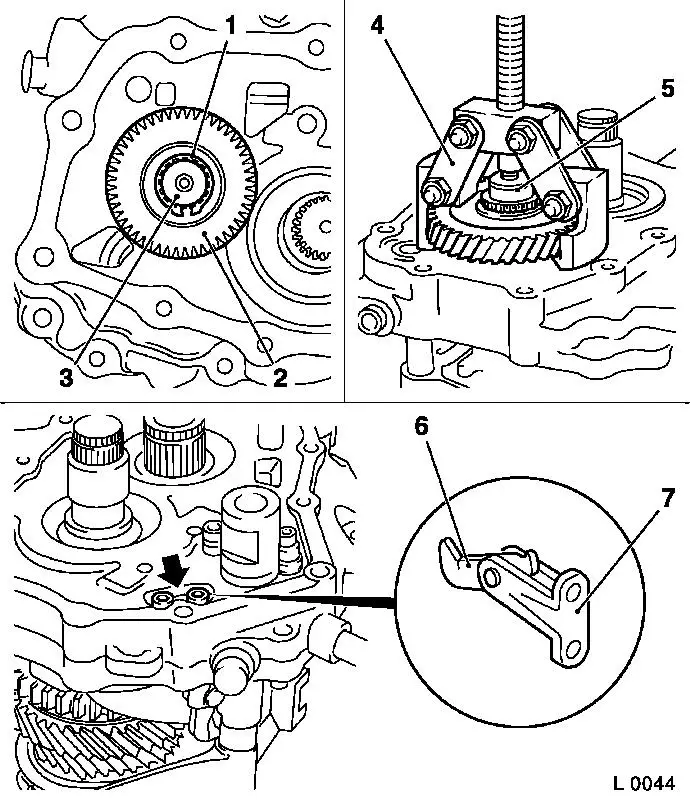

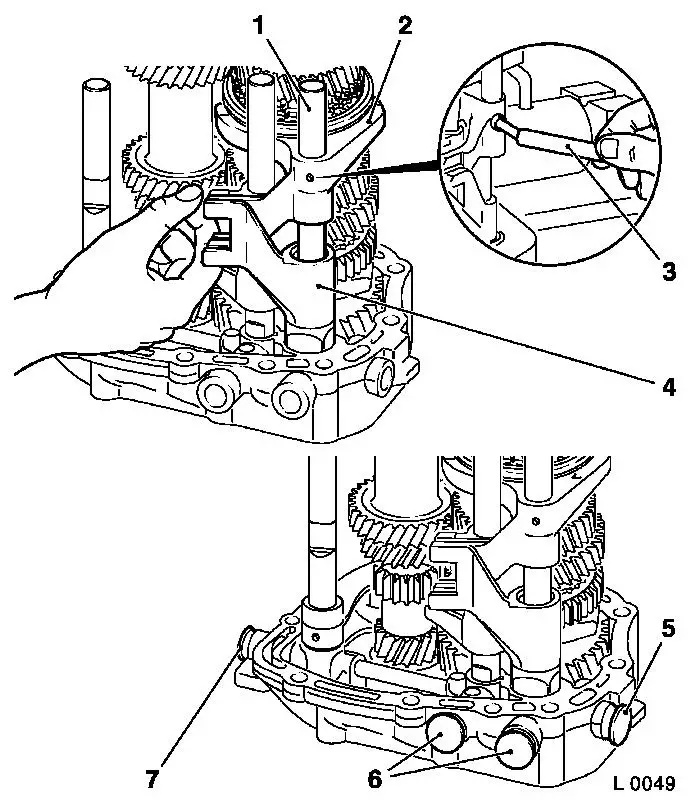

| 8. |

Remove retaining ring (1) of 5th speed gear (driving) (2) from

drive shaft (3)

|

| 9. |

Pull 5th gear gearwheel (driving) from drive shaft with KM-553-A

| • |

Place thrust piece (5) from KM-553-A

(6) onto drive shaft

Note: Ensure KM-553-A is correctly seated on the gear wheel,

5th gear (driving)

|

|

| 10. |

Remove bearing block (7) with latch (6) from end shield

| • |

Unscrew 2x bolt (arrow)

Note: Microencapsulated

bolts. If the bolts are difficult to move, heat the end shield to

approx. 80°C with an industrial hot-air blower.

|

|

|

|

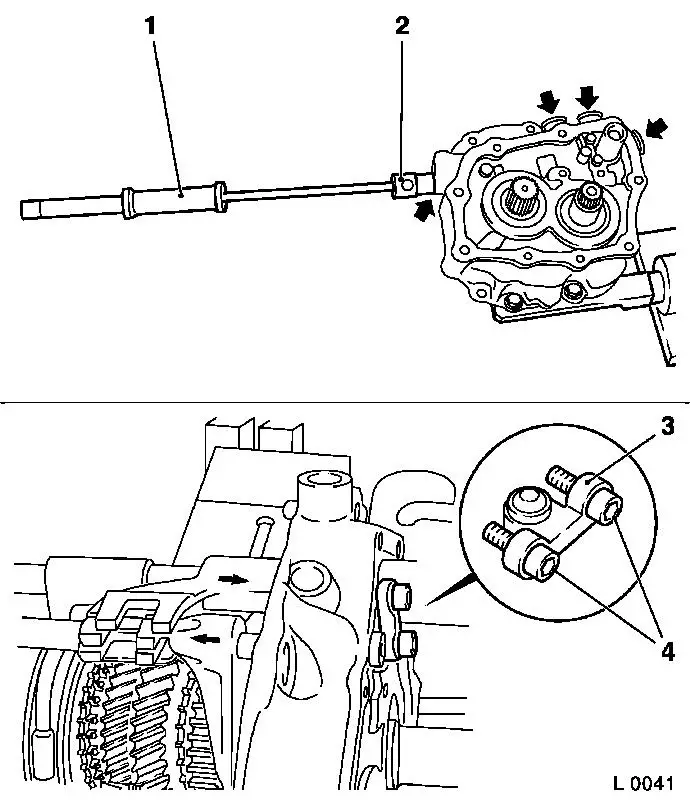

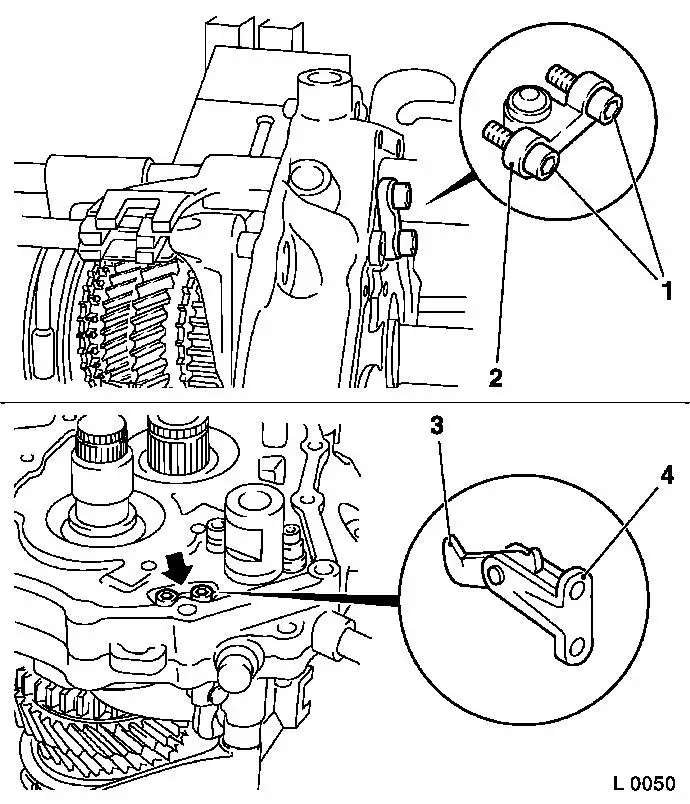

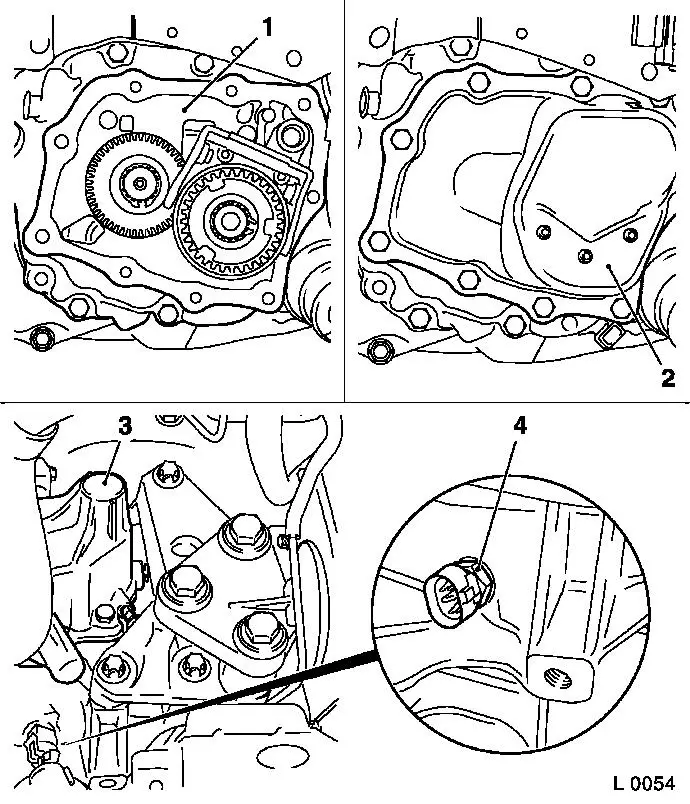

| 11. |

Remove locking plug (arrows) from end shield with KM-727 (2) and KM-328-B

(1)

|

| 12. |

Detach 2 bolts (4) from bridge (3) for locking bolt from end

shield

Note: Microencapsulated

bolts. If the bolts are difficult to move, heat the end shield to

approx. 80°C with an industrial hot-air blower.

|

| 13. |

Engage 2nd gear and 5th gear (with shift driver)

Note: The bridge will

push itself out when 3rd gear is subsequently engaged.

|

|

|

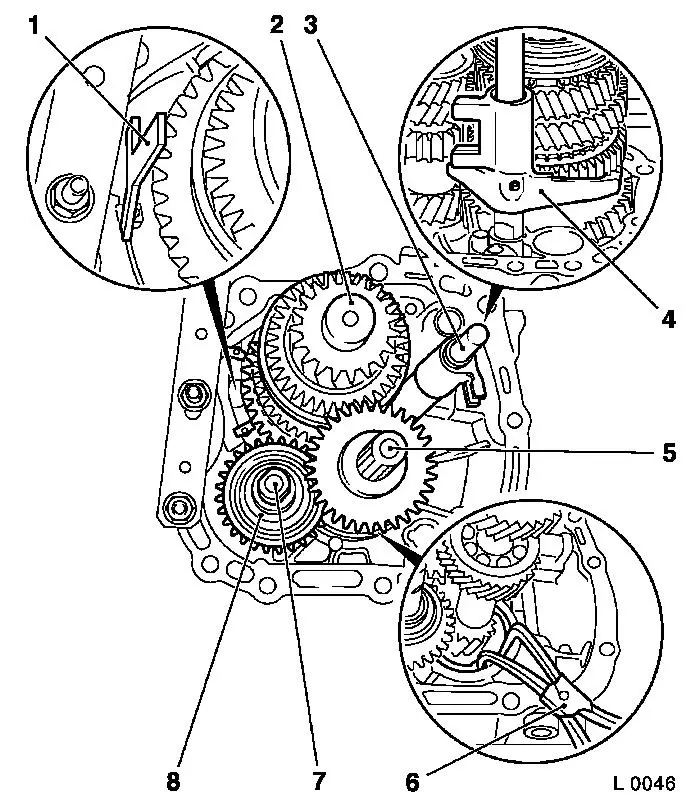

| 14. |

Remove roll pins (arrows) with KM-308

Note: Relieve pressure

on shifter rod guides – for this, support shifter rods above

with wood (1).

| • |

Drive out of 3rd/4th gear shift fork (3)

|

| • |

Drive out of reverse gear shift fork (6)

|

|

| 15. |

Remove 3rd, 4th (3) and reverse gear (6) shifter rods (2) and

shift forks from end shield

|

| 16. |

Remove 5th gear shift driver (4) from end shield

|

| 17. |

Remove locking pin (5) for catch from end shield hole

|

|

|

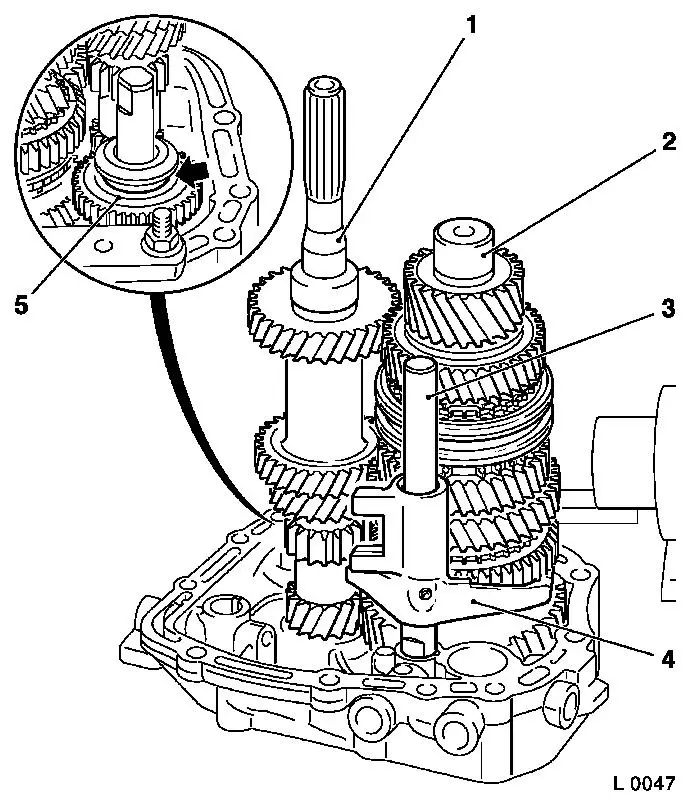

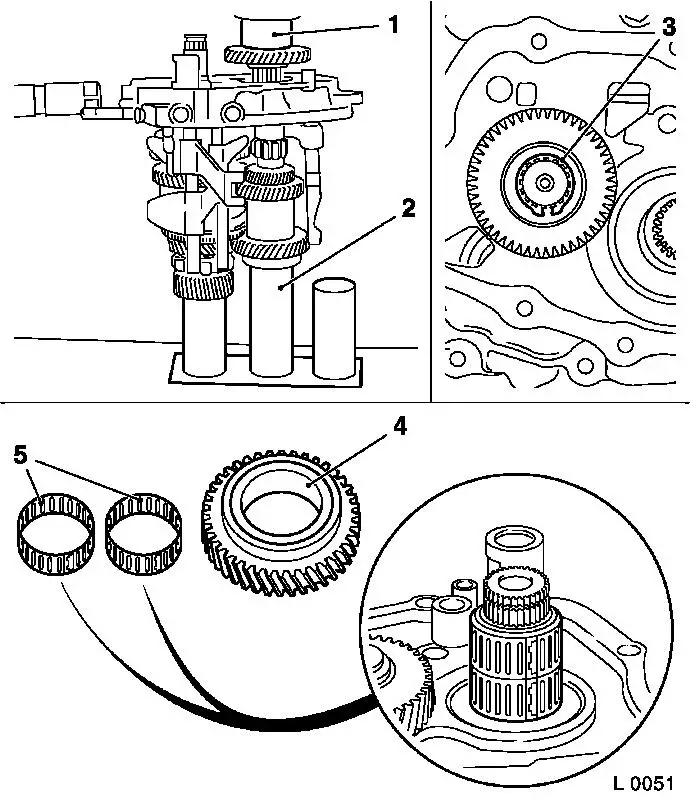

| 18. |

Remove retaining springs for main shaft (2) and drive shaft (5)

from grooves of end shield with KM-443-B

(6)

Note: To assist when

dismantling, keep the retaining ring for the main shaft under

tension with fitting plate (1).

|

| 19. |

Remove main shaft (2) from end shield

|

| 20. |

Remove drive shaft (5) from end shield

|

| 21. |

Remove reverse idler (8) from end shield.

|

| 22. |

Remove shift fork (4) and gearshift rod 1st/2nd (3) gear from

end shield.

|

| 23. |

Remove reverse gear wheel (7)

| • |

Clamp in vice with protective jaws

|

| • |

Carefully knock out end shield with brass drift

Note: Note that

retaining ball is released.

|

|

|

Install

Install

| 24. |

Clean all parts and sealing surfaces

|

| 25. |

Check all parts for wear, scoring, damage and replace if

necessary

|

| 26. |

Lubricate rotating parts on their bearing, running, seating,

and pressure surfaces using transmission fluid.

|

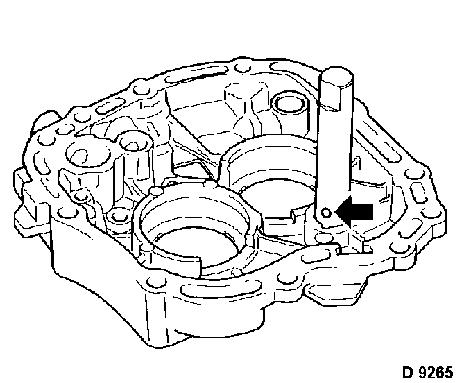

| 27. |

Push reverse gearwheel axis into end shield as far as it will

go

| • |

Insert retaining ball (arrow)

Note: Note installation

position.

|

|

|

|

|

| 28. |

Coat bearing and reverse bore hole with transmission fluid

|

| 29. |

Insert main shaft (2), drive shaft (1), reverse gear wheel (5)

and shift fork (4) with 1st/2nd gear shift rod (3) into end

shield

Note: Shift fork groove

(arrow) for reverse idler gear (5) points upwards.

| • |

Secure with new retaining rings

|

| • |

Insert retaining rings with KM-443-B

Note: Retaining rings

must engage correctly in grooves.

|

|

|

|

| 30. |

Insert 3rd/4th reverse gear locking pin (1)

|

| 31. |

Insert shift fork (5) and reverse gear shift rod (6)

Note: To relieve

pressure on shift rod guides in end shield, support shift rods with

wooden wedge when securing with pin.

|

| 32. |

Allow new locating pin to protrude by approx. 2 mm (Dimension

I).

|

| 33. |

Insert shift fork (3) and shift rod (2) for 1st/2nd gear

|

|

|

| 34. |

Insert 5th gear shift driver (4)

|

| 35. |

Insert gear shift fork (2) and shift rod (1) for 3rd/4th

gear

Note: To relieve

pressure on shift rod guides in end shield, support shift rods with

wooden wedge when securing with pin.

|

| 36. |

Fit locking plugs (5), (6) and (7)

| • |

Drive 4 locking plugs in as far as they will go with plastic

hammer or soft metal drift

|

|

| 37. |

Bring shift fork into neutral position.

|

|

| 38. |

Engage 2nd/3rd/5th gear

|

|

| 39. |

Coat 2 new bolts (1) with locking compound

|

| 40. |

Place bridge for locking bolt onto end shield (2)

| • |

Tighten 2 bolts slightly

|

| • |

Move gearshift fork 1st/2nd gear into neutral

|

|

| 41. |

Bring shift fork into neutral position.

|

| 42. |

Coat 2 new bolts (arrow) with locking compound

|

| 43. |

Fit bearing block (4) with latch (3) to end shield

|

|

| 44. |

Remove end shield with KM-552 from

KM-113-2 .

|

|

| 45. |

Insert end shield with main and drive shaft into KM-554 (2)

|

| 46. |

Press on gearwheel for 5th gear (driving) with KM-514 (1)

Note: Long gear hub

points to end shield.

|

| 47. |

Install new retaining ring (3)

|

| 48. |

Attach end shield with KM-552 to

KM-113-2

|

| 49. |

Place needle bearings (5) for 5th gear gearwheel (4) onto main

shaft

| • |

Coat 2x needle bearing with transmission fluid

Note: Ensure that the

slotted needle bearing is correctly seated

|

|

|

| 50. |

Coat seating surfaces of main shaft and synchro body with

transmission fluid.

|

|

| 51. |

Slide 5th gear gearwheel (2) and synchro body (1) onto main

shaft

Note: Secure with new

retaining ring (3)

|

| 52. |

Insert crosshead shoe (arrow) in 5th gear shift fork (4).

|

| 53. |

Coat new bolts with locking compound

|

| 54. |

Attach bearing bracket to end shield with pivoting lever

|

|

|

| 55. |

Fit friction washer (arrow) on reverse gear shaft

| • |

Stick on friction washer with grease

|

|

|

| 56. |

Before installation of transmission unit check following items

for position and seating:

| 1. |

3rd/4th gear shift fork |

| 2. |

3rd/4th gear shift rod |

| 3. |

5th gear shift driver |

| 4. |

1st/2nd gear shift rod |

| 5. |

1st/2nd gear shift fork |

| 6. |

Lock pin for gear stop |

| 7. |

Reverse gear shift fork |

| 8. |

Reverse gear shift rod |

|

|

| 57. |

Install end shield (1) in transmission

|

| 58. |

Install end shield cover (2) gasket

|

| 59. |

Install reversing lamp switch (4) with new seal ring

|

| 60. |

Install gearshift cover (3)

|

| 61. |

Check transmission fluid level

|

|

|