|

Pressure Loss, Check

|

Engine must be at operating temperature (oil temperature >=

80 °C).

Remove Remove

Remove injection lines – see operation "Injection Lines,

Remove and Install".

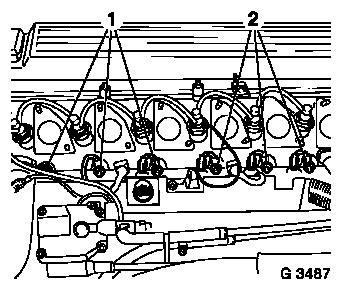

Remove sheathed glow plugs (1 and 2) – see operation

"Sheathed glow plugs, remove and install".

Version with AC: Remove visco-fan – see operation

"Visco-fan, Remove and Install".

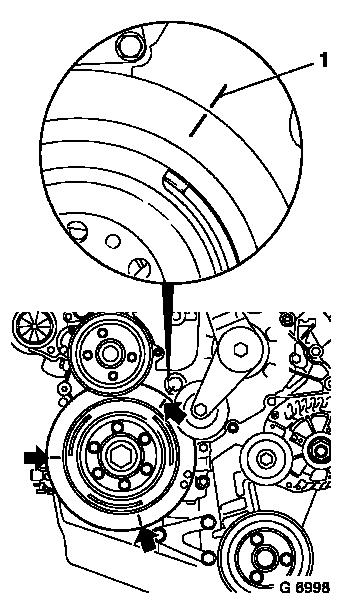

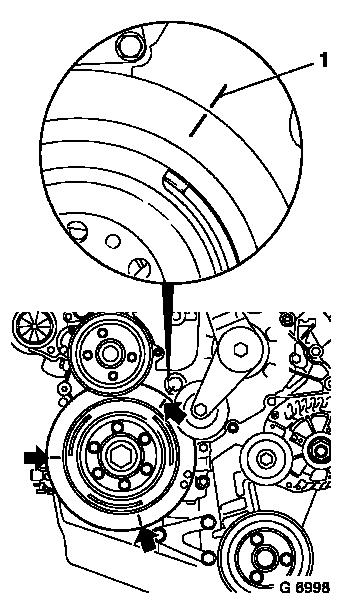

1. Adjust cylinder to "TDC" – see operation "Timing,

Check".

|

|

Inspect

Inspect

|

Position guide mark (1) at suitable point on timing case. Guide

mark "1st Cylinder TDC" on torsional vibration damper and guide

mark on timing case must align.

Make guide markings (arrows) every 120° on torsional

vibration damper.

Remove Remove

Remove oil filler opening cap, coolant compensation tank cap and

dipstick.

Caution

The crankshaft is not permitted to rotate during the test

procedure. In order to avoid this, engage 1st gear or selector

lever position "P" and apply parking brake.

|

|

Install

Install

|

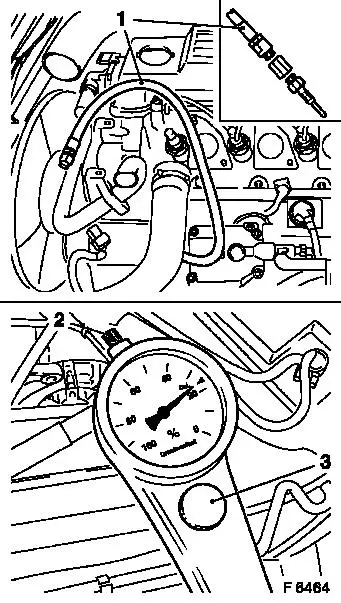

Screw Adapter KM-488 with Connection Piece KM-533-B and

connection hose (1) in threaded bore of sheathed glow plugs –

tightening torque 22 Nm / 16 lbf. ft.

Connect pressure loss tester to a compressed air system and

connect test nozzle (2). Calibrate the compressed air tester by

turning the knurled thumb screw (3). Connect test hose to

connecting piece.

Inspect

Inspect

Max. pressure difference between individual cylinders 10%. Max.

cylinder pressure loss should not exceed 25%

For the following components, note any escaping air in order to

localise damage: intake ducts, exhaust, coolant compensation tank,

dipstick guide tube and sheathed glow plug threaded bores.

|

|

Inspect

Inspect

|

Check pressure loss at cylinders 2. to 6. accordingly. Turn

crank shaft in accordance with guide markings (arrows) on torsion

vibration damper. Guide markings must correspond with guide marking

(1) on timing case. Injection order: 1-5-3-6-2-4.

Remove Remove

Remove Adapter KM-488 and Connection Piece KM-533-B. Uncouple

pressure loss tester from compressed air system.

|

|

Install

Install

Install oil filler opening closure cap, coolant compensation

tank closure cap and oil dipstick.

Install sheathed glow plugs – see operation "Sheathed glow

plugs, remove and install".

Install injection lines – see operation "Injection Lines,

Remove and Install".

Version with AC: Install visco-fan – see operation

"Visco-fan, Remove and Install".

|