|

Main Shaft, Disassemble and Assemble (R 25/R 28/R

30)

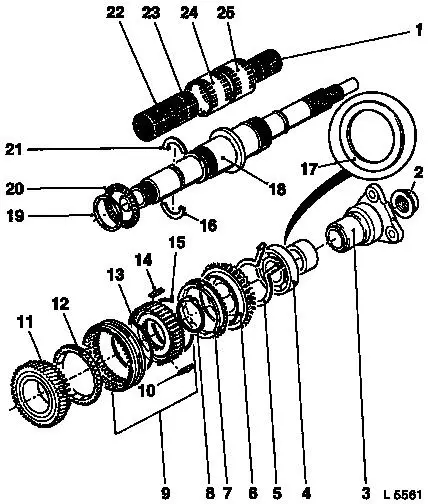

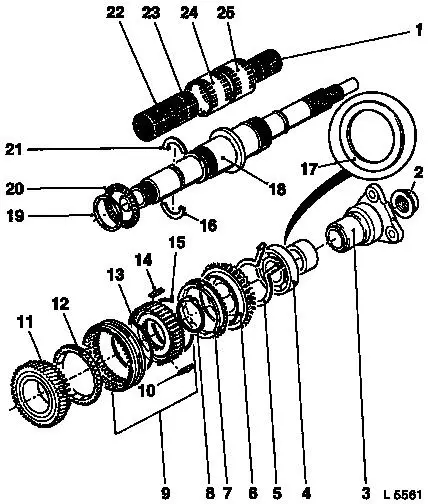

Illustration

|

1

|

Needle bearing, 5th gear

|

|

2

|

Main shaft fastening nut

|

|

3

|

Main drive clutch assembly

|

|

4

|

Main shaft ball bearing

|

|

5

|

Retaining ring

|

|

6

|

Gear wheel, 5th gear

|

|

7

|

Synchroniser ring

|

|

8

|

Retaining ring

|

|

9

|

5th gear synchromesh body assembly

|

|

10

|

Sliding block

|

|

11

|

Gear wheel, reverse gear

|

|

12

|

Synchroniser ring

|

|

13

|

Spring

|

|

14

|

Sliding block

|

|

15

|

Spring

|

|

16

|

Thrust washer

|

|

17

|

Supporting disk (all R 30 and R 25 / R 28 as of MY 2001)

|

|

|

|

18

|

Main shaft

|

|

19

|

Retaining ring

|

|

20

|

Axial bearing, 1st gear

|

|

21

|

Thrust washer

|

|

22

|

3rd gear needle bearing

|

|

23

|

2nd gear needle bearing

|

|

24

|

1st gear needle bearing

|

|

25

|

Reverse gear needle bearing

|

|

|

|

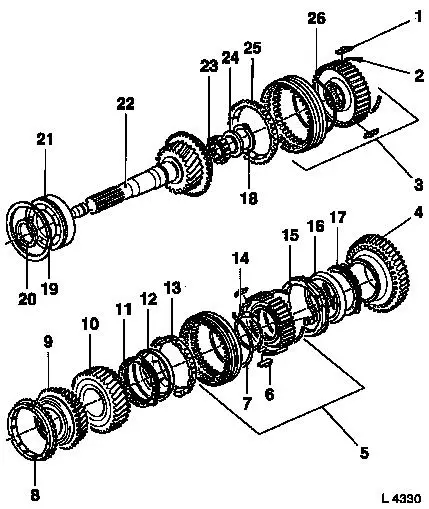

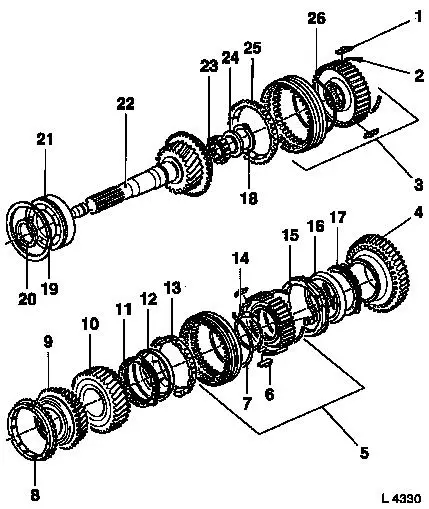

1

|

Sliding block

|

|

2

|

Spring

|

|

3

|

3rd/4th gear synchromesh body assembly

|

|

4

|

1st speed gear

|

|

5

|

1st/2nd gear synchromesh body assembly

|

|

6

|

Sliding block

|

|

7

|

Spring

|

|

8

|

Synchroniser ring

|

|

9

|

3rd speed gear

|

|

10

|

Gear wheel, 5th gear

|

|

11

|

Inner synchroniser ring

|

|

12

|

Intermediate ring

|

|

13

|

Outer synchroniser ring

|

|

14

|

Retaining ring

|

|

15

|

Inner synchroniser ring

|

|

16

|

Intermediate ring

|

|

17

|

Outer synchroniser ring

|

|

18

|

Retaining ring

|

|

|

|

19

|

Retaining ring (large)

|

|

20

|

Retaining ring (small)

|

|

21

|

Ball bearing

|

|

22

|

Drive shaft

|

|

23

|

Needle bearing

|

|

24

|

Gasket

|

|

25

|

Synchroniser ring

|

|

26

|

Spring

|

|

|

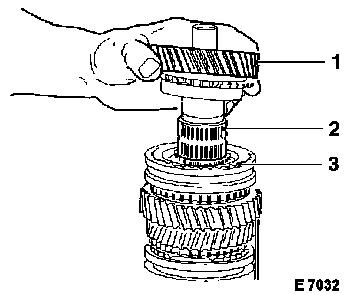

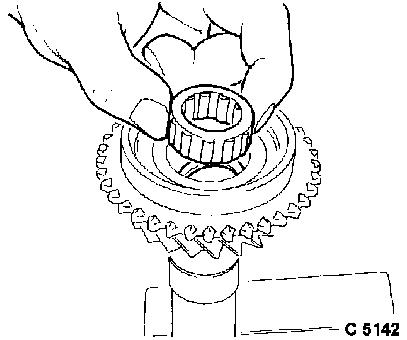

Remove Remove

|

Disassemble transmission – see operation "Transmission,

Disassemble and Assemble".

Auxiliary shaft gear cluster from main shaft.

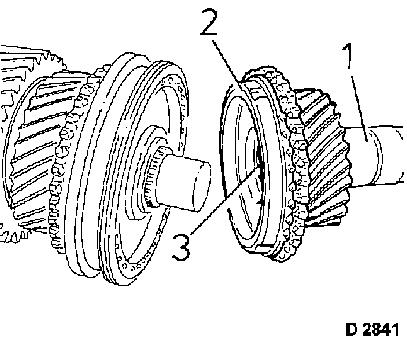

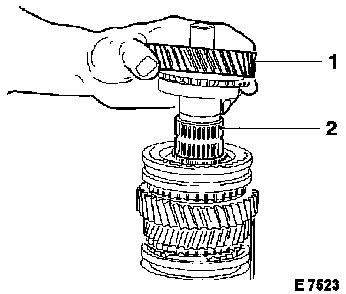

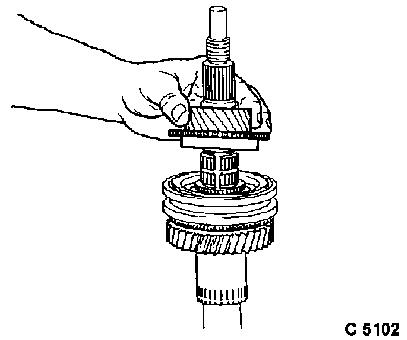

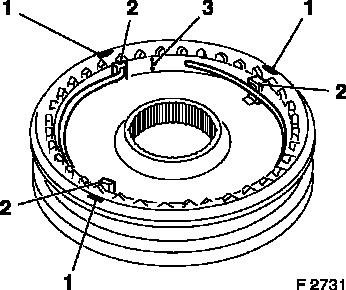

Main drive gear (1) with synchroniser ring of 4th gear (2) and

needle roller bearing (3) from main shaft.

|

|

|

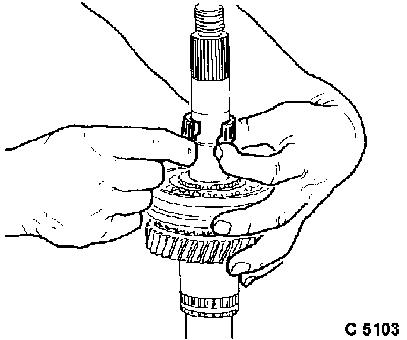

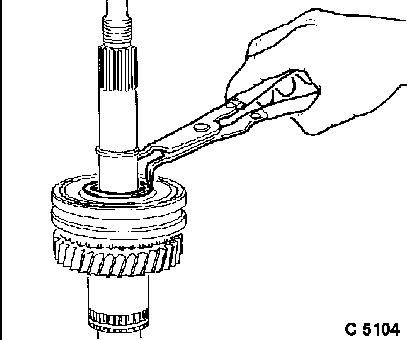

Clamp main shaft in vice – use protective jaws, drive side

of main shaft (without thread attachment) faces upwards.

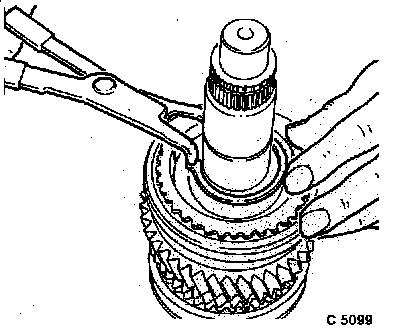

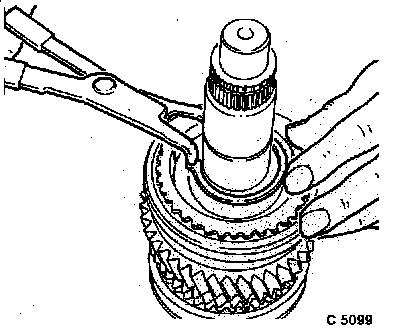

Retaining ring from main shaft, retaining ring pliers.

|

|

|

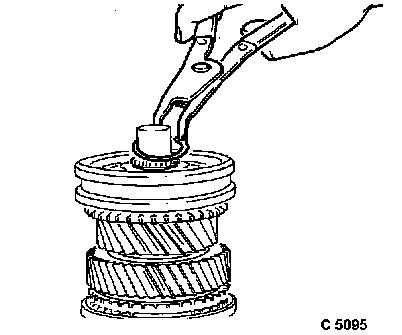

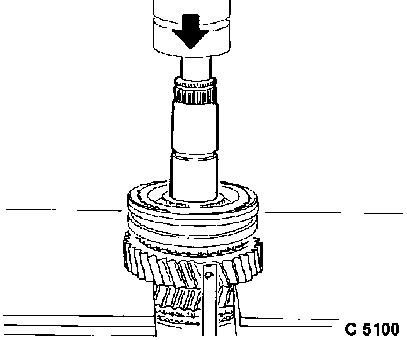

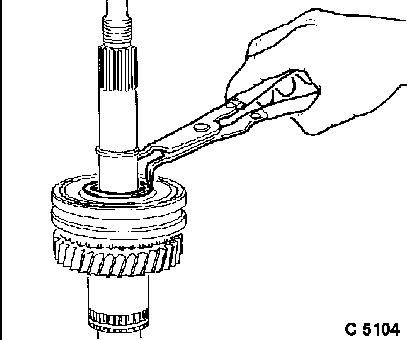

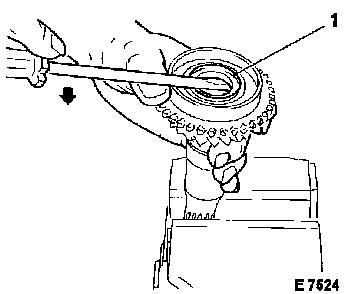

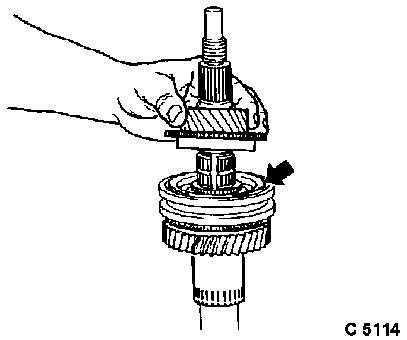

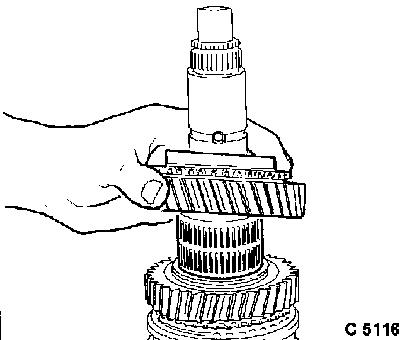

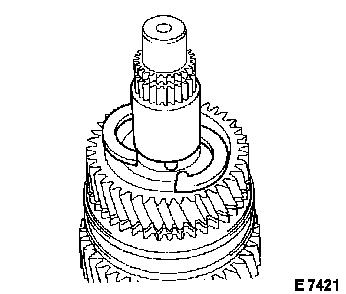

Press 3rd/4th synchromesh body (1), synchroniser ring, 3rd gear

(2) and needle roller bearing from main shaft, KM-307-B. Push

KM-307-B under 3rd gear.

Press off main shaft.

|

|

|

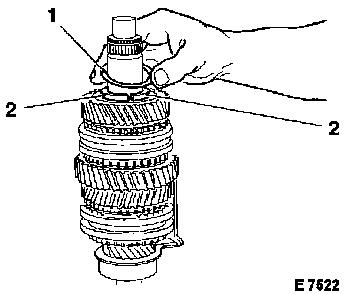

Clamp main shaft in vice with drive side upwards.

Retaining ring (1) and both thrust washer halves (2) from main

shaft.

|

|

|

2nd gear (1) with 3 cone synchromesh unit from main shaft,

needle roller bearing (2) from main shaft.

|

|

|

Retaining ring for 1st/2nd synchromesh body from main shaft

using retaining ring pliers.

|

|

|

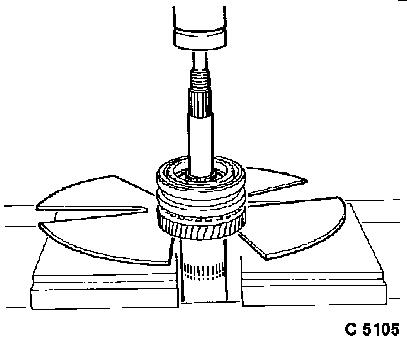

Press off synchromesh body, 3 cone synchromesh unit, 1st gear by

placing 1st gear on 2 flat irons.

|

|

|

Ball bearing of main shaft – KM-307-B. Push KM-307-B under

bearing as far as possible and press main shaft off bearing.

Caution

Align retaining ring to bearing outer ring and attach while

pressing off.

|

|

Remove Remove

|

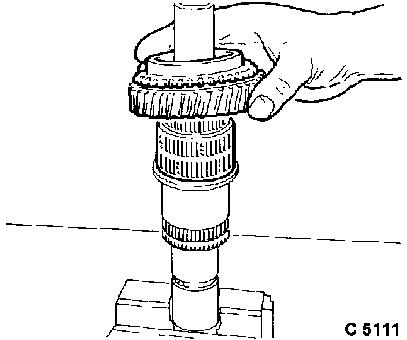

Clamp main shaft in vice with drive side upwards.

5th gear from main shaft.

|

|

|

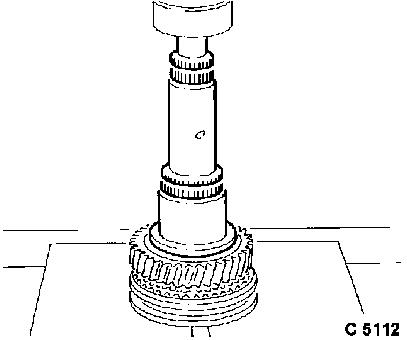

Slotted needle roller bearing for 5th gear from main shaft,

unhook needle roller bearing and spread carefully.

|

|

|

Retaining ring for 5th/reverse synchromesh body from main

shaft.

Press off 5th/reverse synchromesh body, synchroniser ring and

reverse gear from main shaft using KM-307-B.

Caution

Do not use recess of main shaft behind synchromesh body as

support.

|

|

|

Remove Remove

Slotted needle roller bearing for reverse gear from main shaft,

unhook needle roller bearing and spread carefully.

|

|

|

Lever seal ring (1) out of from main drive gear.

Needle roller bearing and, if present, spacer from main drive

gear.

Inspect

Inspect

Removed parts for damage and wear.

Caution

If auxiliary shaft gear cluster or the gears are damaged,

replacement of the whole gear cluster is recommended to avoid

running noises.

|

|

Assemble

Assemble

|

Before assembling the main shaft, complete synchromesh bodies.

Only one version is described on the following pages since this

operation is the same for all synchromesh bodies. Identification

and special installation position of the respective synchromesh

bodies are indicated in the assembly of the main shaft.

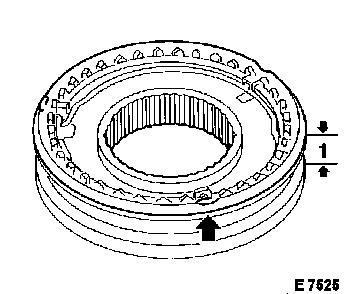

1st/2nd synchromesh body, identification: 1 groove (arrow) on

shift sleeve, overall width (1) is 24.0 mm/0.94 in.

|

|

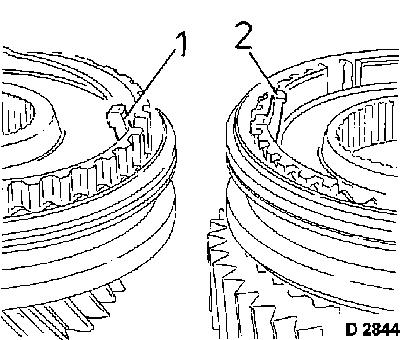

Caution

|

Do not mix up sliding blocks.

Different sliding blocks are used for the 3rd/4th synchromesh

body and 5th/reverse (1, ball-type version) than for the 1st/2nd

synchromesh body (2, narrow version).

|

|

Caution

|

3rd/4th gear synchromesh body:

Identification: 2 grooves (1) on shift sleeve, small diameter at

inner teeth of synchromesh bodies.

|

|

|

The 4th gear synchroniser spring is interlaced by 10 mm/0.4 in.

(3). Interlacing points away from contact surface. The sliding

blocks (2) are opposite the counterbore (1).

|

|

Caution

|

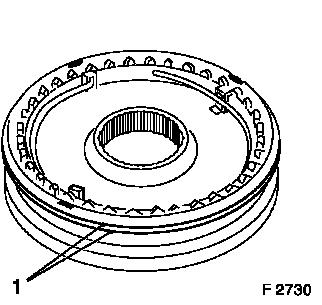

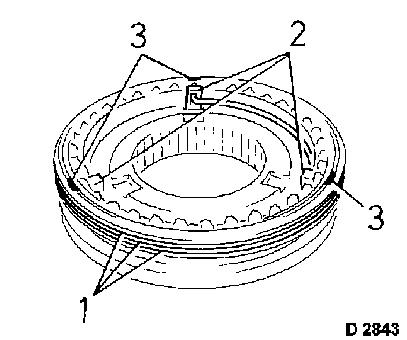

5th/reverse synchromesh body:

Identification: 3 grooves (1) on shift sleeve, the sliding

blocks (2) are opposite the counterbore (3).

|

|

Assemble

Assemble

|

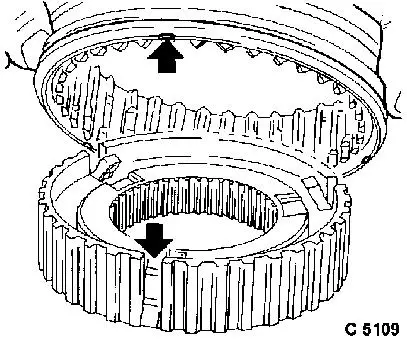

Synchromesh body

Push shift sleeve onto synchromesh body, insert sliding blocks

in slots in synchromesh body (arrow, bottom).

Caution

Notches on shift sleeve (arrow, top) and raised collar of

synchromesh bodies point in one direction.

|

|

Install

Install

|

Install synchroniser springs.

Both springs of one synchromesh body are seated in the same

sliding block, but face opposite directions.

Caution

Synchroniser spring of 4th gear is interlaced. Interlacing is 10

mm. The loose end of the spring points away from contact

surface.

|

|

Install

Install

|

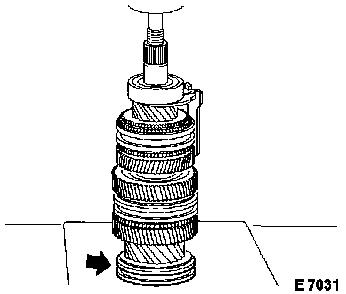

Clamp main shaft in vice using soft jaws (output side

upwards).

Needle roller bearing (slotted version), reverse gear and

molybdenum-coated synchroniser ring to main shaft.

|

|

|

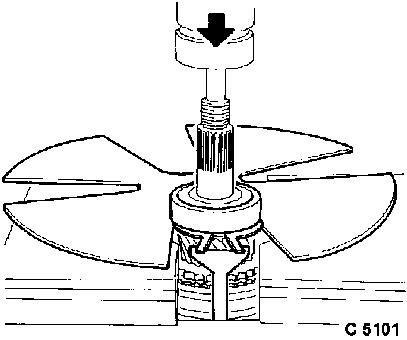

Heat pre-installed synchromesh body reverse gear/5th gear to

approx. 100 °C – use thermocolour pencils or suitable

temperature gauge. Press synchromesh body onto main shaft –

identification grooves point to the previously installed reverse

gear wheel (raised belt of the synchromesh body points upwards).

Only install 5th gear synchroniser ring after pressing on, so that

this is not damaged when pressing the synchromesh body in.

|

|

Caution

|

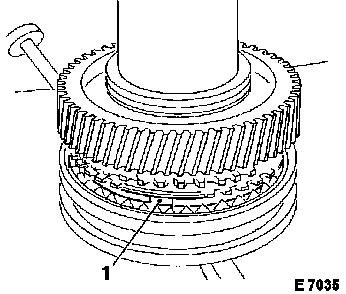

When pressing into position, ensure that sliding blocks are

inserted into recesses (1) of synchroniser ring. If necessary,

lever up synchroniser rings slightly using screwdriver, so that

they are seated freely on cone of gear (do not jam). If necessary,

align sliding blocks and recesses by turning on the reverse

gear.

|

|

Install

Install

|

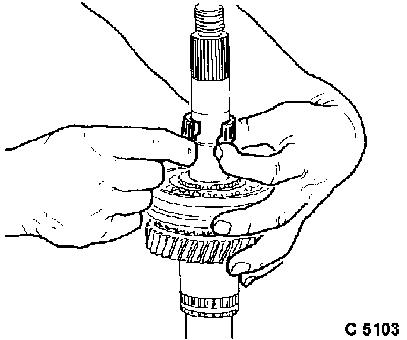

Retaining ring for synchromesh body to main shaft, retaining

ring pliers. Ensure it is correctly seated in groove.

|

|

|

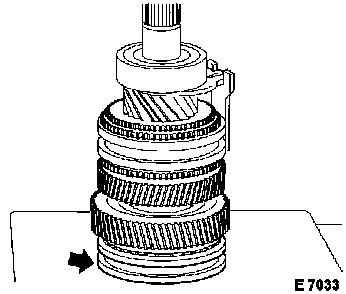

Needle roller bearing for 5th gear to main shaft – spread

slightly and mount over shoulder on main shaft.

|

|

|

5th synchroniser ring (arrow) to main shaft, 5th gear to main

shaft.

|

|

|

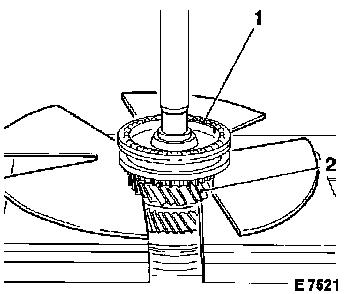

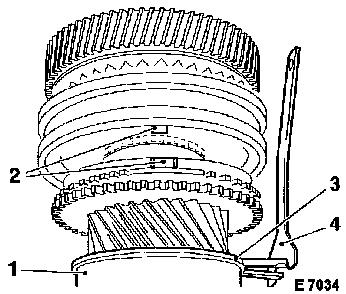

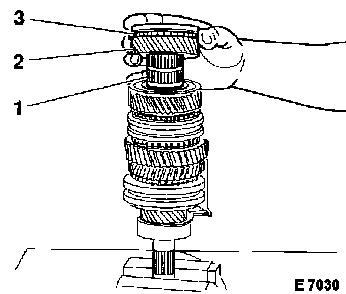

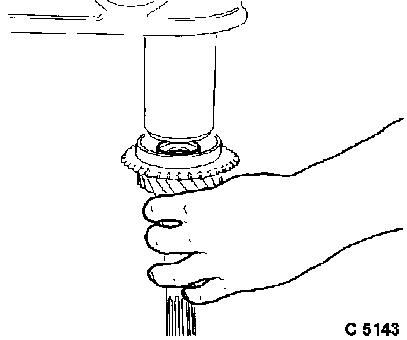

Put on retaining ring (3) for rear main shaft bearing (1),

tension using KM-627-1-A (4) and put on behind 5th gear. Push main

shaft bearing (1) onto main shaft and press main shaft into

bearing.

Caution

When pressing bearing on, ensure that recesses of synchroniser

ring (2) are pressed exactly over sliding blocks of synchromesh

body. If necessary, turn 5th gear.

|

|

Install

Install

|

Clamp main shaft in vice with output side downwards.

Axial needle roller bearing (1) and radial needle roller bearing

(2) to main shaft.

|

|

|

1st gear to main shaft.

|

|

|

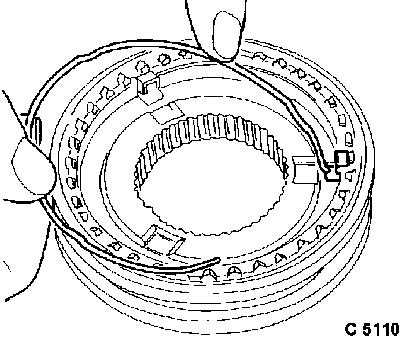

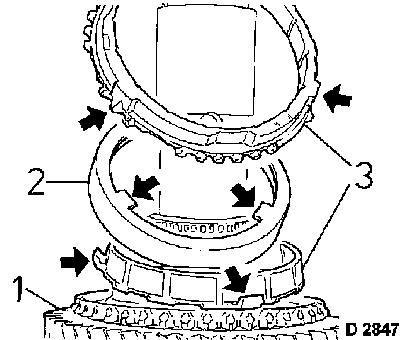

Attach 3 cone synchromesh unit to 1st gear (1).

Align lugs with the appropriate recesses. Note that these are

sometimes on the inside (2) and sometimes on the outside of the

synchroniser rings (3).

|

|

|

Heat pre-installed 1st/2nd synchromesh body to approx. 100

°C/212 °F, use thermocolour pencils or suitable temperature

gauge. Press synchromesh body onto main shaft, identification

groove of shift sleeve (arrow) points to input side of main

shaft.

Caution

The sliding blocks must be seated in respective recesses of

synchroniser ring. If necessary, align by turning 1st gear.

|

|

Install

Install

|

Retaining ring for synchromesh body to main shaft, retaining

ring pliers. Ensure it is correctly seated in groove.

|

|

|

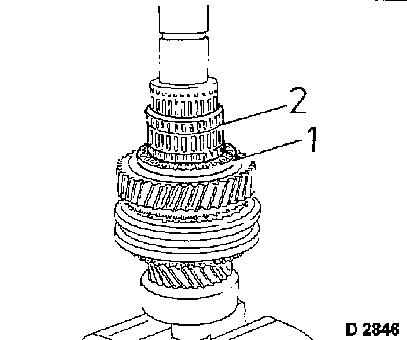

Needle bearing (2), synchromesh body cone (3) and 2nd gear (1)

on main shaft.

See also Illustration D 2847 when completing 1st gear.

|

|

|

Insert 2 thrust washer halves with lugs into main shaft. Secure

thrust washer halves with retaining ring.

|

|

|

Needle bearing (1), synchroniser ring (3) and 3rd gear (2) on

main shaft.

|

|

|

Heat pre-installed 3rd/4th gear synchromesh body to approx. 100

°C/212 °F – use thermocolour pencils or suitable

temperature gauge. Press synchromesh body onto main shaft –

identification groove (arrow) of shift sleeve points to drive side

of main shaft.

Caution

Press 3rd gear upwards using screwdriver, so that 3rd

synchroniser ring is not jammed during pressing on.

|

|

Install

Install

|

Retaining ring for 3rd gear to main shaft. Install 4th

synchroniser ring only after pressing on.

Grease new needle bearing and if available, place in main drive

gear with spacer washer.

|

|

|

Press seal ring in flush to main drive gear using suitable

sleeve.

Closed side of seal ring faces towards needle roller

bearing.

Assemble transmission, see operation "Transmission, Disassemble

and Assemble".

|

|

|