|

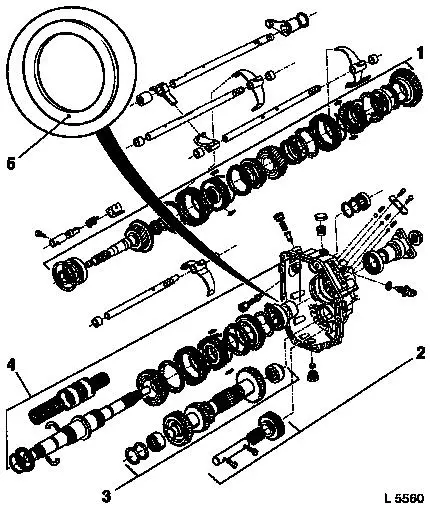

Dismantling and assembling transmission (R 25/R

28/R 30)

|

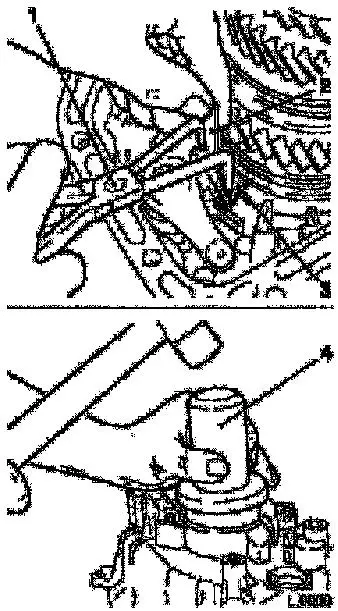

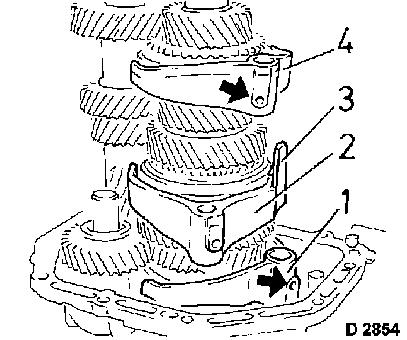

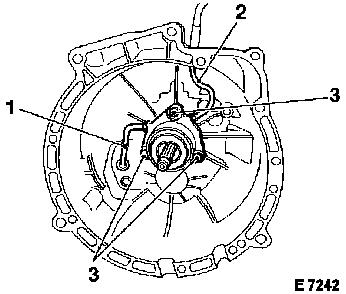

Illustration – Assemblies

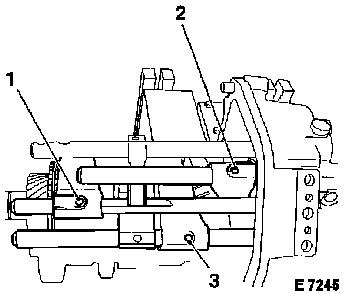

| 1. |

Drive shaft assembly |

| 2. |

Reverse idler gear shaft assembly |

| 3. |

Auxiliary shaft gear cluster assembly |

| 4. |

Main shaft assembly |

| 5. |

Supporting disk (additional for all R 30 and for R

25 / R 28 transmissions as of MY 2001) |

|

|

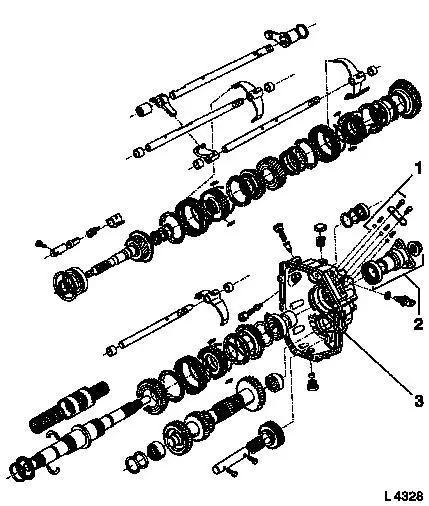

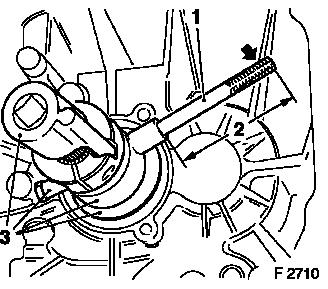

| 1. |

Lock ball assembly |

| 2. |

Drive shaft flange assembly |

| 3. |

Transmission extension assembly |

|

|

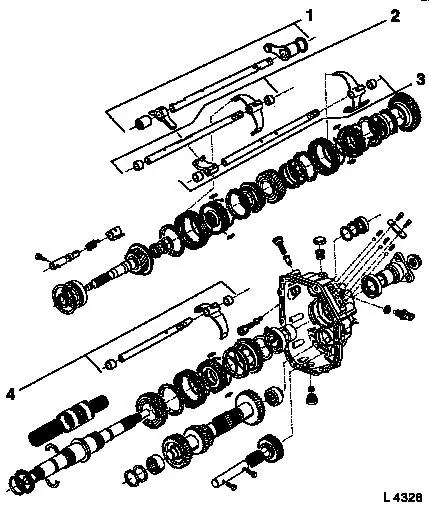

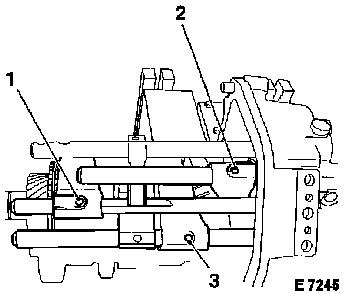

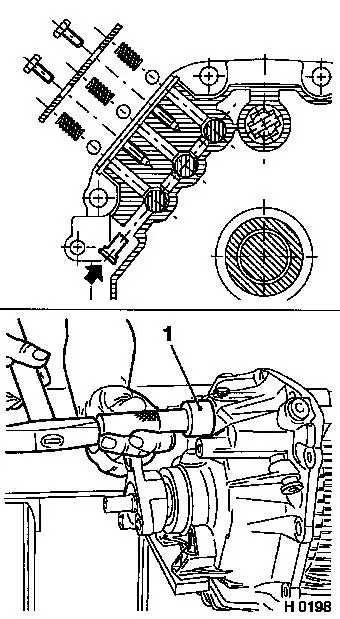

| 1. |

Shift lever shaft assembly |

| 2. |

3rd/4th gear shift rod assembly |

| 3. |

1st/2nd gear shift rod assembly |

| 4. |

5th/reverse gear shift rod assembly |

|

|

Remove Remove

|

Removing transmission - see operation "Removing and installing

manual transmission (vehicles with 4-cylinder petrol engine)",

"Removing and installing manual transmission (X 20 DTH, Y 22 DTH)",

"Removing and installing manual transmission (25 DT, X 25 DT)",

"Removing and installing manual transmission (Y 25 DT) or "Removing

and installing manual transmission (vehicles with V6 engine)".

Install

Install

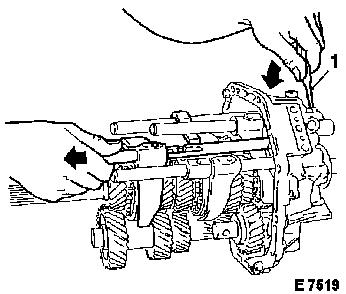

KM-622 to transmission nose piece, transmission to KM-113-2.

|

|

|

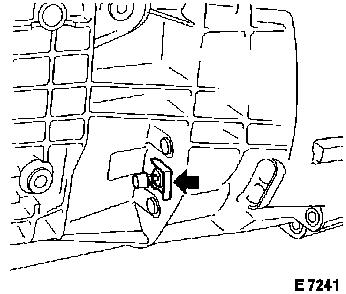

Remove Remove

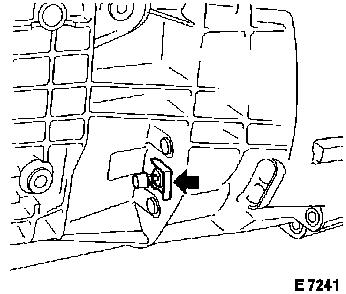

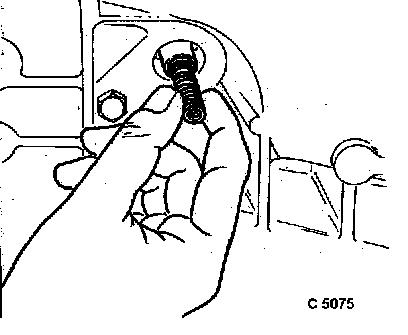

Remove retaining plate (arrow) for vent line –

commercially available pliers.

|

|

|

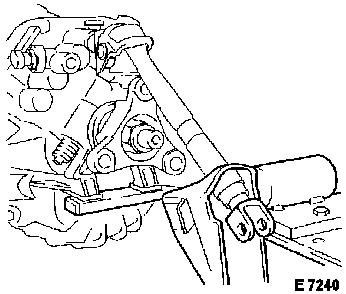

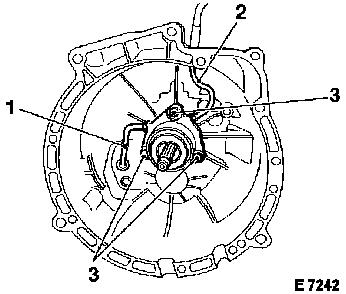

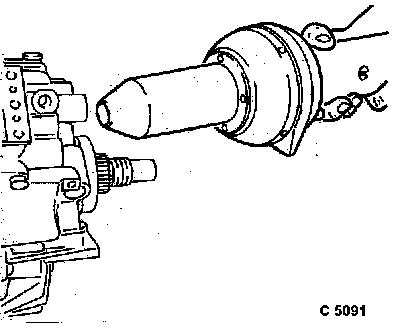

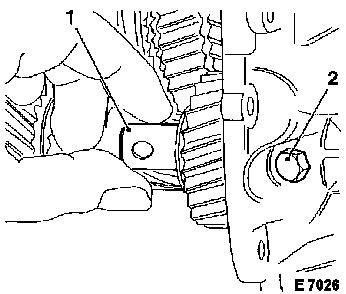

Unscrew pressure line (2) from central release.

Loosen vent line (1) at central release.

Release central release from transmission, 3 bolts (3).

Remove entire central release with vent line (1). Unscrew vent

line from central release.

Pull pressure line (2) out of transmission housing with rubber

sleeve.

|

|

|

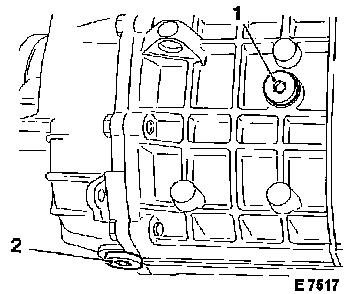

Fluid filler plug (1) from right transmission side, fluid drain

plug (2) from transmission nose piece.

Drain transmission fluid.

|

|

|

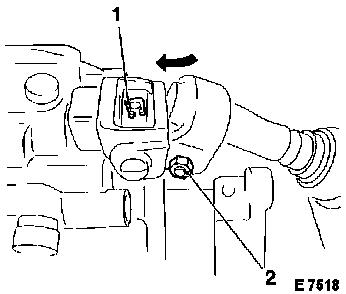

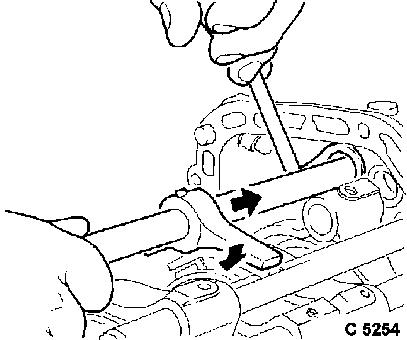

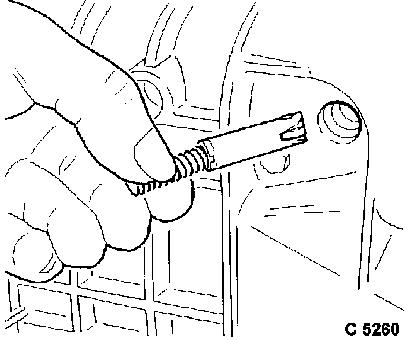

Connecting piece with shift rod from shift lever shaft.

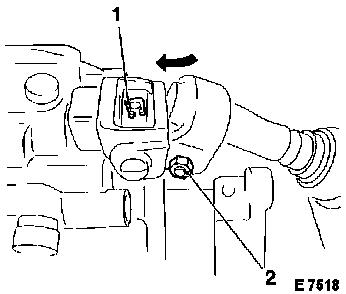

Fold folding cover forwards (arrow), detach retaining clip (1),

drive out pin with suitable drift and hammer.

Caution

Outer shift rod (2) remains attached.

|

|

Remove Remove

|

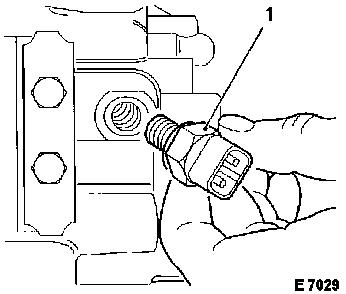

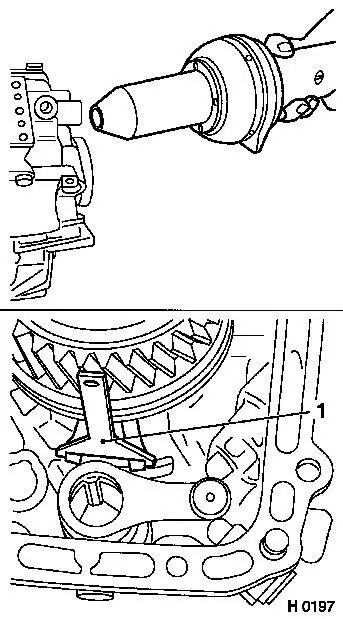

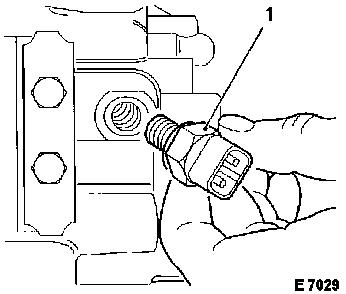

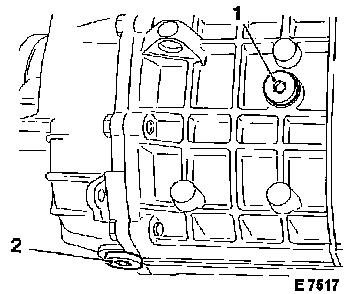

Unbolt reversing lamp switch (1) from transmission. Note spacer

ring.

|

|

|

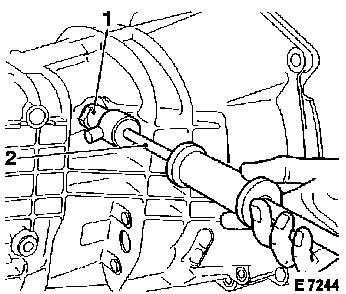

Knock 1 closure plug (1) for locking bolt out of transmission

housing, KM-630-1 (1) and KM-328-B (2) (right transmission

side).

|

|

|

Remove locking bolt with pressure spring from front section of

transmission housing.

|

|

|

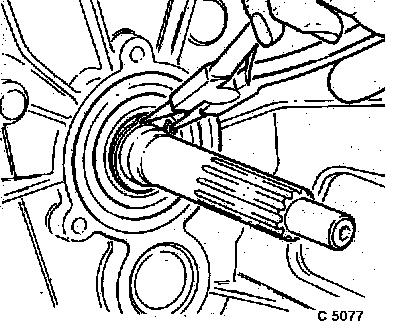

Remove retaining ring from bearing of main drive gear.

|

|

|

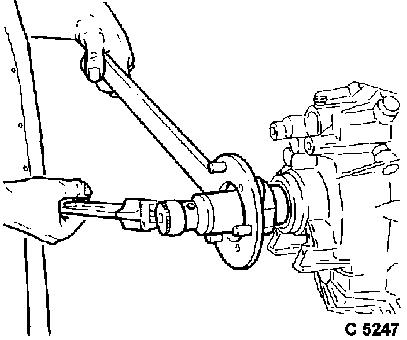

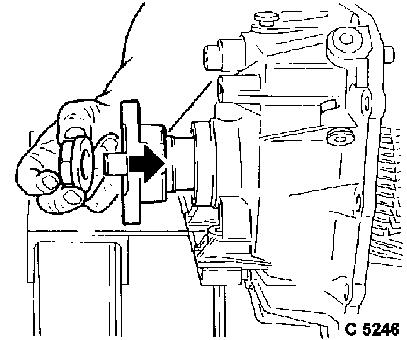

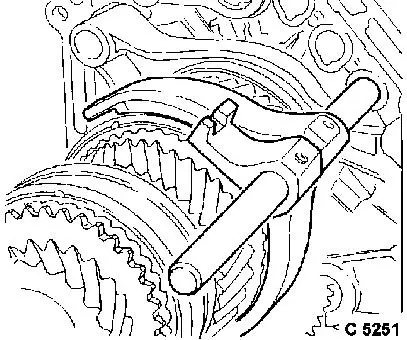

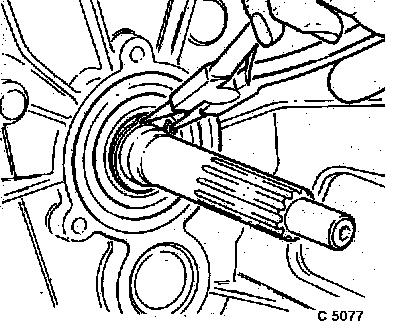

Output shaft flange from transmission, counterhold with KM-623

and unscrew using hex socket (size 30, extra long).

|

|

|

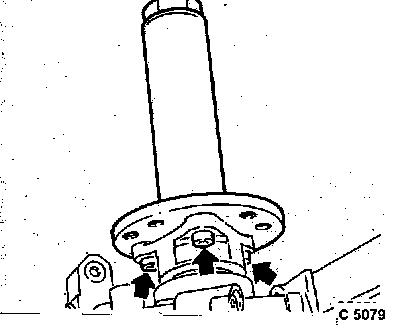

Turn transmission vertically downwards. Install KM-628-A with 3

screws to output shaft flange (arrows).

|

|

|

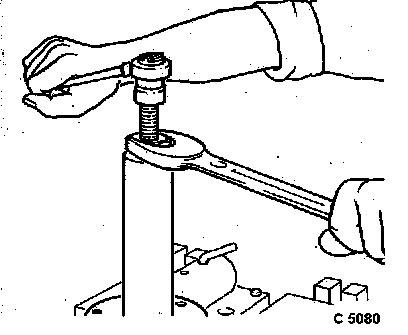

Screw KM-628-A in flush – counterhold at hex and remove

output shaft flange.

|

|

|

Turn transmission to horizontal position.

Unscrew fastening bolt for reverse idler gear shaft.

|

|

|

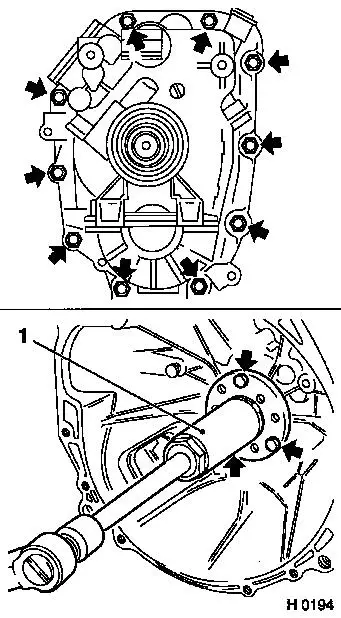

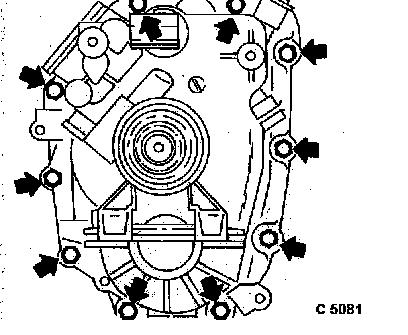

10 fastening bolts for transmission nose piece (arrows).

Install

Install

Fasten KM-628-A (1) to transmission housing with central release

fastening bolts.

Remove Remove

Remove transmission housing from transmission nose piece using

KM-628-A, bearing for main drive gear remains in housing.

|

|

|

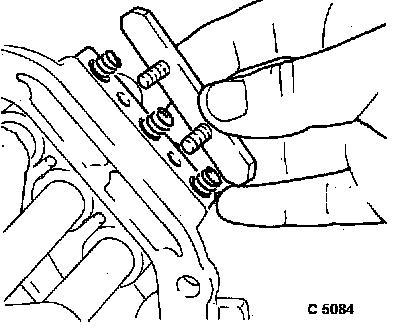

Cover for stop balls from transmission.

Caution

Cover under spring pressure.

Remove Remove

Pressure springs from transmission.

|

|

|

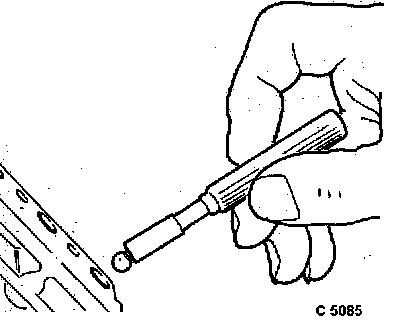

3 stop balls from transmission using bar magnet.

|

|

|

Grooved pins for shift forks using

drift.

|

Shift fork, 1st/2nd gear (1),

|

|

Shift fork, 3rd/4th gear (2),

|

|

Shift fork, 5th/reverse gear (3).

|

|

|

|

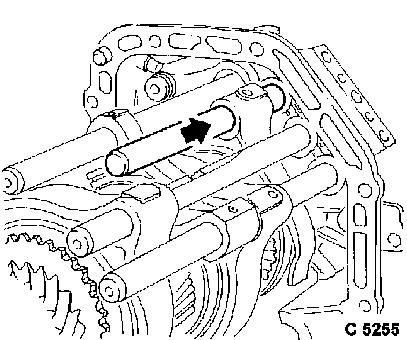

Pull shift rods out of shift forks, remove shift rods from

transmission nose piece.

If necessary, twist shift shaft (1) so that shift finger does

not handicap removal of shift rods.

|

|

|

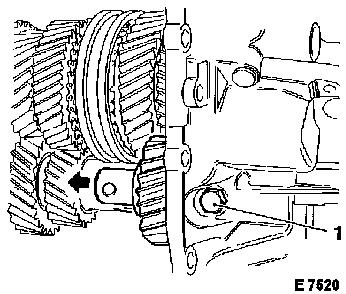

Fastening screw for reverse idler shaft (1) from transmission

nose piece, pull out reverse idler shaft slightly and remove with

reverse gear in direction of arrow.

|

|

|

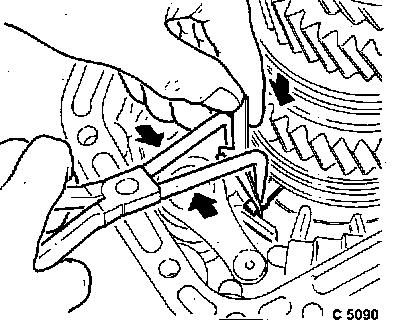

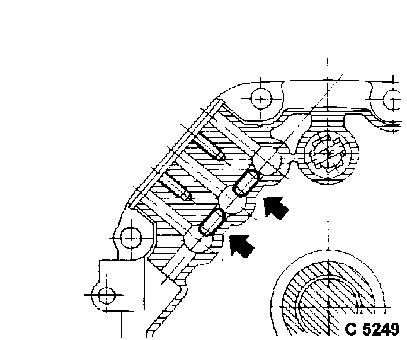

Compress retaining ring for main shaft bearing with KM-627. Hold

retaining ring tensioned – apply KM-627-1-A from above.

|

|

|

Heat transmission nose piece in area of main shaft bearing seat

to approx. 100 °C/212 °F using industrial hot air

blower.

Check temperature with thermocolour pencils or suitable

temperature gauge.

|

|

|

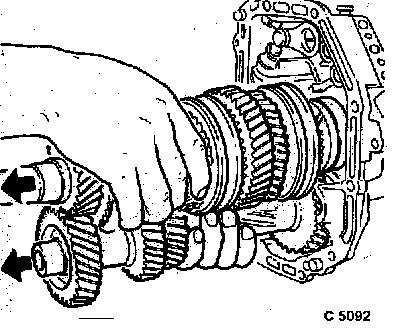

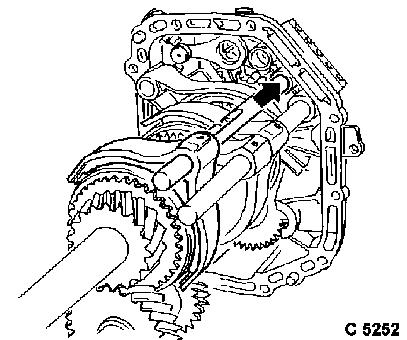

Remove main shaft and auxiliary shaft gear cluster from

transmission nose piece.

|

|

Install

Install

|

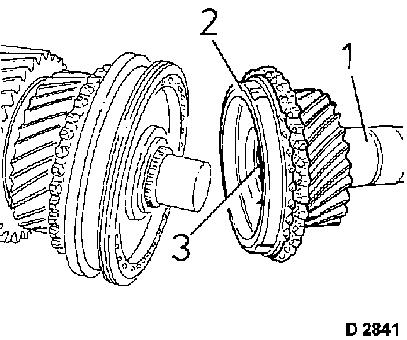

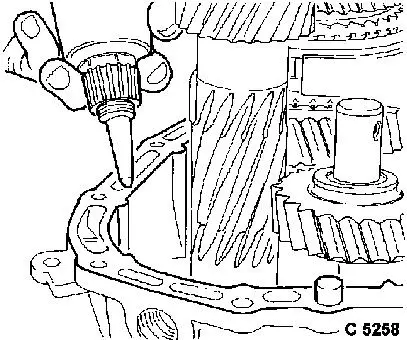

Install main drive gear (1) with synchroniser ring (2) and

bearing cage (3) onto main shaft.

|

|

|

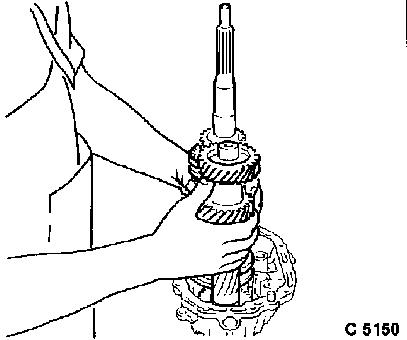

Assemble auxiliary shaft gear cluster and main shaft.

Assembled main shaft with auxiliary shaft gear cluster in

transmission nose piece.

|

|

|

Heat transmission housing nose piece in area of bearing seat to

approx. 100 °C/212 °F, industrial hot air blower,

thermocolour pencils or suitable temperature gauge.

Caution

Position of retaining ring. Do not jam retaining ring at

transmission nose piece. Insert KM-627-1 (1) opposite rocker on

retaining ring.

|

|

Remove Remove

|

Remove KM-627-1 (2) from retaining ring (3) – remove

tensioner, adjust with retaining ring pliers (1) so that retaining

ring engages in groove.

Install

Install

Drive new seal ring for output shaft flange into transmission

nose piece with KM-629-1 (4).

|

|

|

Drive shaft flange onto teeth of main shaft, insert new

fastening nut with locking compound.

|

|

Torque

|

Counterhold drive shaft flange with KM-623 – hexagon

wrench (A/F 30, extra long) – 150 Nm / 111 lbf. ft.

|

|

Install

Install

|

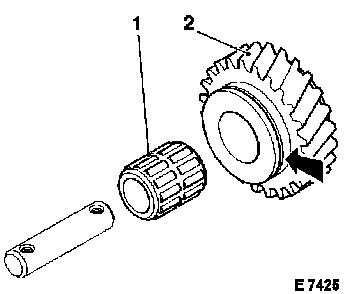

Install double-row needle roller bearing (1) in reverse idler

gear (2). Insert reverse idler gear in transmission. Identification

groove (arrow) points to driving direction.

|

|

|

Push reverse idler gear shaft (1) through until rear screw (2)

can be inserted into nose piece.

Torque

Reverse idler gear shaft to transmission – 22 Nm / 16 lbf.

ft.

|

|

Install

Install

|

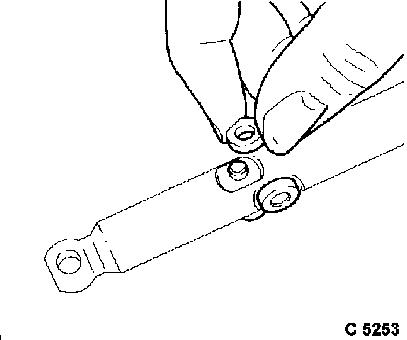

Coat 2 locking pins for gearshift rods with lubricating grease

and insert with bar magnet into transmission nose piece.

|

|

|

All shift forks onto respective sliding sleeve:

5th/reverse shift fork (1): Recognisable by offset, the rounded

heel (arrow) points to the drive side.

1st/2nd shift fork (2): Lubricating duct (3) points to the drive

side.

3rd/4th shift fork (4): Shift fork has no offset, the rounded

heel (arrow) points to the output side.

|

|

|

Push 1st/2nd shift rod with shift driver through shift fork and

place in transmission nose piece. Align bore holes for grooved

pin.

Caution

All sliding sleeves are in idle position.

|

|

Install

Install

|

Install 3rd/4th shift rod in shift fork, so that recesses point

away from 1st/2nd shift rod. Insert 3rd/4th shift rod in centre

bore hole in transmission nose piece, so that bore holes for

grooved pins align.

|

|

|

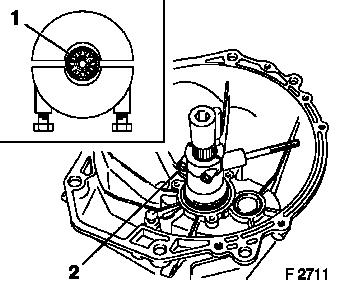

Place 4 rollers on shift lever shaft and adhere by inserting

with lubricating grease.

|

|

Caution

|

Install shift lever shaft with shift finger into selector rocker

in transmission nose piece.

Position of shift finger, turn selector rocker slightly if

necessary.

|

|

Install

Install

|

5th/reverse shift rod into shift fork and transmission nose

piece, so that bore holes for grooved pin are aligned.

|

|

|

Drive 3 grooved pins (1, 2, 3) into shift forks and shift rods

using KM-308.

Caution

Support shift rod ends (e.g. using wooden block). Drive in

grooved pins, so that they protrude approx. 1 mm/0.04 in.

|

|

Install

Install

|

Insert 3 locking balls and 3 pressure springs into transmission

nose piece.

Torque

Cover – install with sealing compound at transmission nose

piece (2 bolts) – 10 Nm / 7.5 lbf. ft.

Install

Install

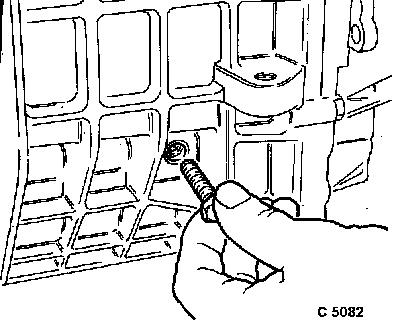

Closure plugs (arrow) for locking pins at transmission nose

piece – drive in fluid-tight with plastic hammer.

Drive in seal ring for shift lever shaft flush with KM-629-3

(1). Turn transmission to vertical position. Engage 4th gear.

Caution

All synchroniser rings must be loosely seated. Loosen firmly

seated synchroniser rings from cone of gear.

|

|

Install

Install

|

Apply sealing compound to sealing surface of transmission nose

piece.

Front section of transmission housing to transmission nose

piece. Ensure that shift rods are inserted correctly into bore

holes in transmission.

Ball bearing with retaining ring to main drive gear.

|

|

|

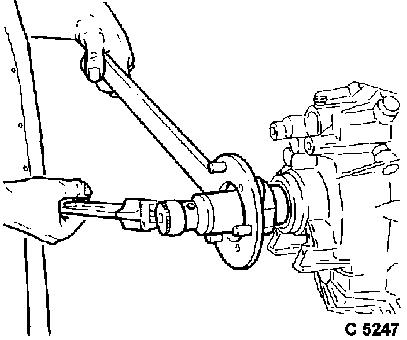

Place bushing KM-461-3 (1) on drive shaft, lubricate moving

parts of Tool KM-461-C. Screw holder rod into KM-461-C to stop.

Slide KM-461-C with holder rod over bushing KM-461-3 and tighten

bolts (2).

|

|

|

Length (2) of holder rod (1) can be varied by screwing into or

out of the thread.

Unscrew holder rod (1) from KM-461-C until end of holder rod

lies on a reinforcement rib (arrow).

Heat transmission housing in bearing seat area to approx. 100

°C. Use industrial hot air blower and thermocolour pencils or

suitable temperature gauge.

Press ball bearing flush to retaining ring in front section of

transmission housing using KM-461-C (3) by turning on square drive

shaft (1/2").

|

|

|

Retaining ring to main drive gear, retaining ring pliers.

Put transmission into idle position.

Inspect

Inspect

Ensure that output flange can be turned in all transmission

gears.

|

|

Torque

|

Install 10 screws (arrows) of transmission nose piece – 22

Nm / 16 lbf. ft.

|

|

|

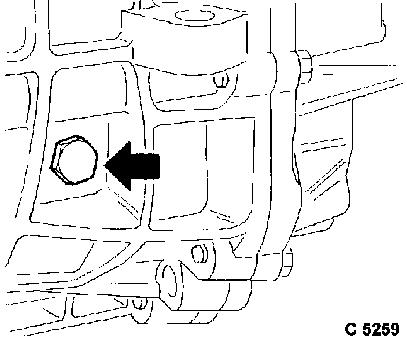

Front screw (arrow) of reverse idler gear shaft – 22 Nm /

16 lbf. ft.

|

|

Install

Install

|

Pre-install vent line (1) to central release.

Torque

Central release to transmission (3 screws, 3) – 22 Nm / 16

lbf. ft.

Attach pressure line (2) with grommet

and bolt to central release – 14 Nm / 10 lbf. ft.

|

Vent line (1) to central release – 14 Nm / 10.5 lbf.

ft.

|

|

Vent line to vent line – 9 Nm / 6 lbf. ft.

|

|

|

|

Install

Install

Retaining plate (arrow) for vent line.

|

|

|

Pressure spring (white marking) and pin (with roller in

horizontal position) into transmission.

Drive in cover using plastic mallet. For widened bore hole, an

oversized cap is available.

|

|

Torque

|

Switch for reversing lamps with spacer (1) – 20 Nm / 15

lbf. ft.

|

|

Install

Install

|

Install connecting piece (2) with outer shift rod, install pin

and retaining clamp (1). Folding cover.

Torque

Fluid drain bolt (2 in illus. E 7517) – 30 Nm / 22 lbf.

ft.

|

|

|

Top up transmission fluid up to 9 mm beneath the fluid filler

bore hole (1) – approx. 1.2 litres – see also operation

"Fluid Level, Check and Correct". Fluid quality – see

"Technical Data".

Torque

Fluid filler plug – 30 Nm / 22 lbf. ft.

Remove transmission from KM-113-2 and KM-622.

|

|

Install

Install

Installing transmission - see operation "Removing and installing

manual transmission (vehicles with 4-cylinder petrol engine)",

"Removing and installing manual transmission (X 20 DTH, Y 22 DTH)",

"Removing and installing manual transmission (25 DT, X 25 DT)",

"Removing and installing manual transmission (Y 25 DT) or "Removing

and installing manual transmission (vehicles with V6 engine)".

|