|

Electric Fuel Pump, Remove and Install (all

Engines)

Note: Operation also

includes the removal and installation of the pre-fuel feed pump in

the 25 DT, X 25 DT.

Caution

Observe safety precautions and national regulations.

Use draining equipment to drain the fuel tank. Draining

equipment – refer to Opel/Vauxhall Workshop Equipment

Catalogue. Store drained fuel in a suitable sealable container.

Remove Remove

Open bonnet and disconnect battery

Remove panelling from luggage compartment floor, remove assembly

aperture cover from floor panel.

Detach fuel pump wiring harness plug, mark fuel hoses. Close off

fuel hoses with spring clamps. Detach fuel supply line and fuel

return line.

|

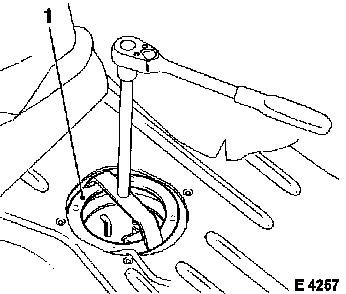

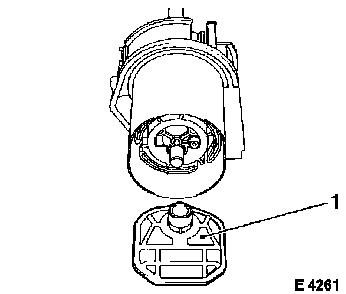

Remove fuel tank cover union nut with KM-673 (1).

|

|

|

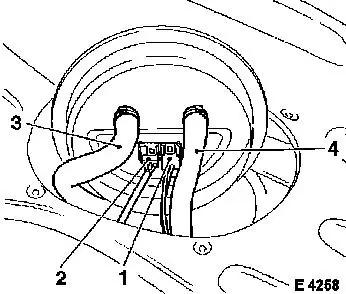

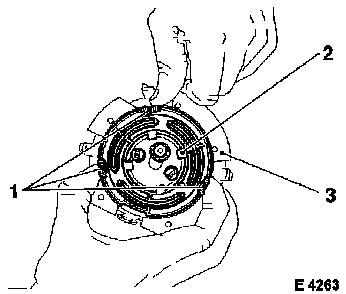

Raise fuel tank cover and detach wiring harness plugs (1) and

(2).

Detach fuel supply line (3) and fuel return line (4) from fuel

tank cover.

|

|

|

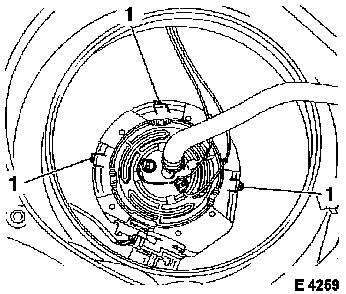

Press lock tabs (1) inwards and hold compressed.

|

|

|

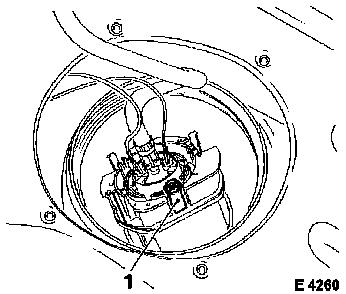

Remove fuel pump housing with lug (1) from storage pot using

suitable hook.

Keep suitable basin at hand and place fuel pump housing in

it.

|

|

|

Mark installation position of fuel screen (1) and remove from

fuel pump.

Detach wiring harness plug and fuel hose from fuel pump.

|

|

|

Press catches (1) inward and simultaneously slide lock ring (2)

out of fuel pump housing (3).

Remove locking ring and fuel pump from fuel pump housing.

|

|

|

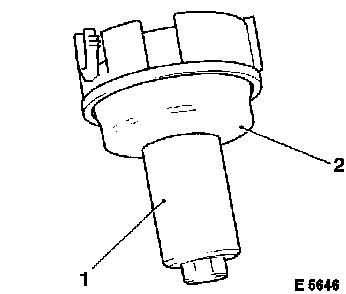

In 25 DT and X 25 DT: Pull fuel pump (1) from sealing sleeve

(2).

|

|

Install

Install

In 25 DT and X 25 DT: Insert fuel pump in sealing sleeve. New

seal ring at fuel pump housing.

All engines: insert fuel pump – fuel pump intake pipe

engages in recess in floor of fuel pump housing.

Insert locking ring in fuel pump housing – catches must

engage in lugs. Connect wiring harness plug to fuel pump –

note polarity of connections!

Fasten fuel hose to fuel pump. Fuel screen to fuel pump –

note installation position. Insert fuel pump housing in storage pot

– catches must engage audibly in storage pot.

New rubber seal ring to fuel tank cover. Connect wiring harness

plug and fasten fuel feed and return lines. Install fuel tank cover

union nut with KM-673 – 50 Nm / 37 lbf. ft. Attach fuel feed

and return lines to fuel tank cover – note installation

position. Remove spring clamps. Connect fuel pump wiring harness

plug.

Note: For Y 25 DT:

Hose clamp for supply hose has a green marking, hose clamp for

return hose has a black marking.

Attach assembly aperture cover to floor panel. Install panelling

in luggage compartment floor.

Refill with drained fuel. Observe safety rules and national

regulations!

For X 20 DTH, Y 22 DTH: Bleed fuel system – see operation

"Fuel System, Bleed (X 20 DTH, Y 22 DTH)".

In 25 DT and X 25 DT: Bleed fuel system – see operation

"Fuel System, Bleed (25 DT, X 25 DT)".

Connect battery, program volatile memories - see operation

"Volatile Memories, Program"

Close bonnet

|