Golf Mk1

|

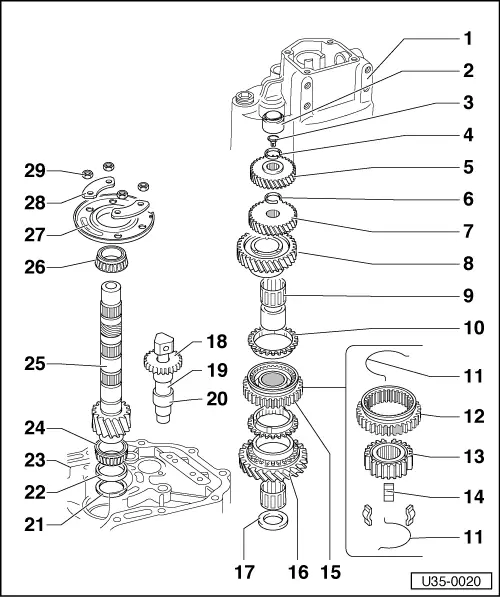

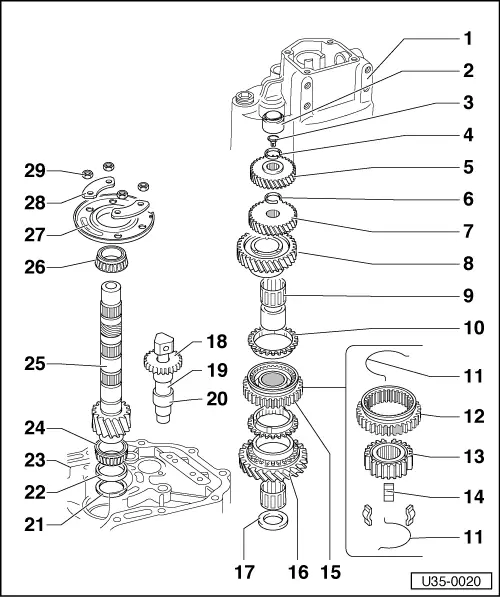

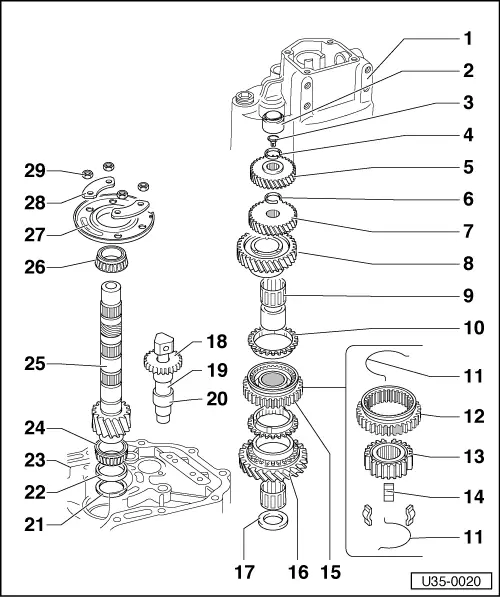

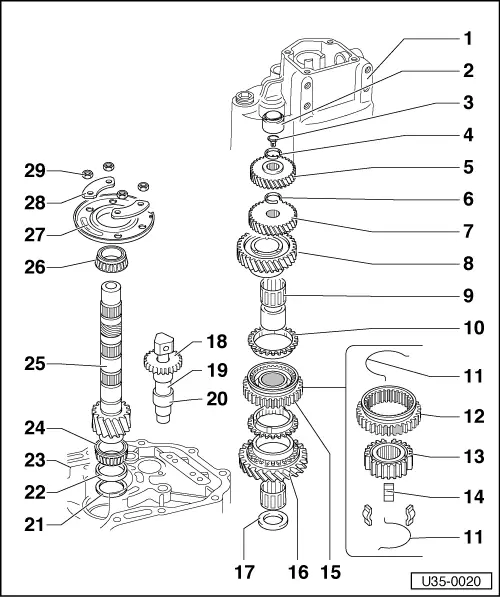

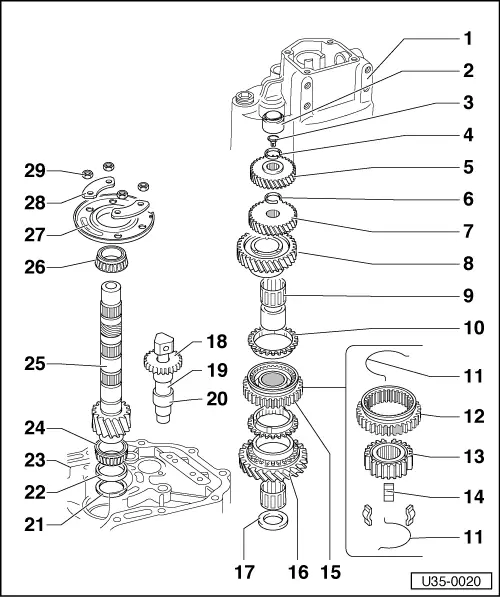

Dismantling and assembling input shaft

Dismantling and assembling output shaft

|

|

|

|

Note: Always renew both bearings and then adjust output shaft, When installing new gears, note Technical Data, => page 00-3 Securing the output shaft needle roller bearing, => page 35-50 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

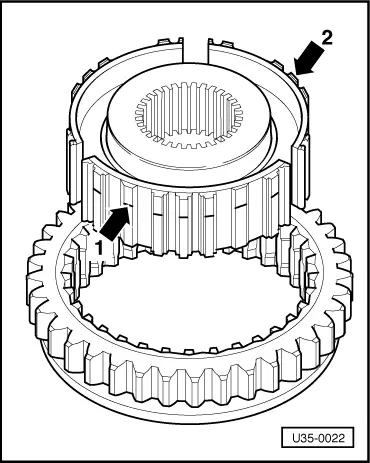

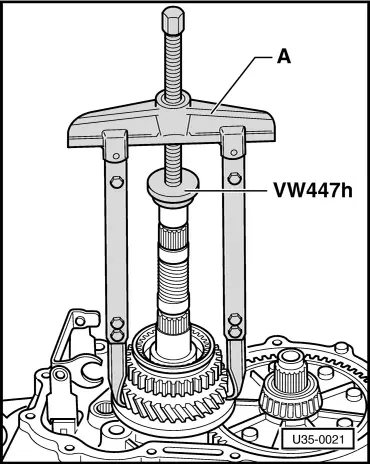

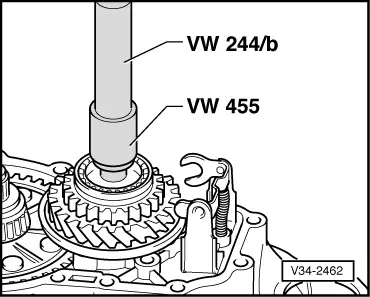

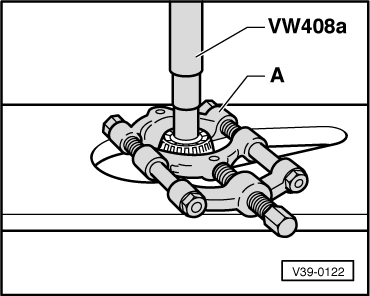

→ Fig.1 Pulling off hub/sleeve and 1st speed gear

|

|

||||||

|

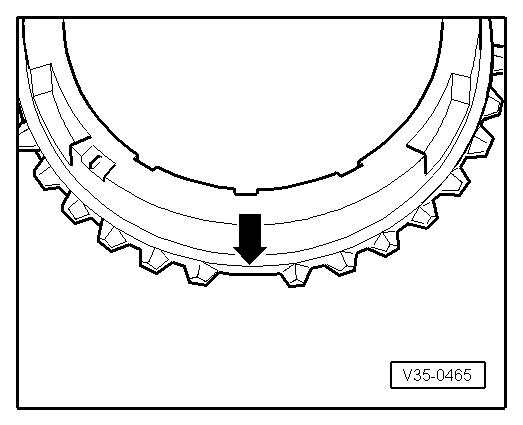

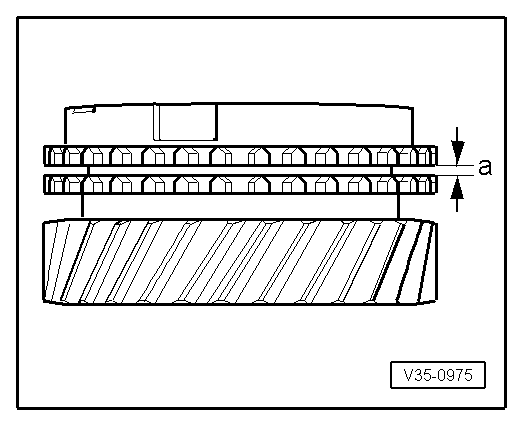

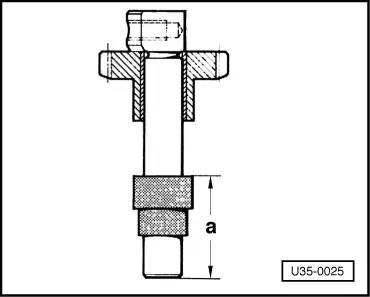

→ Fig.2 Checking synchronizer rings Press synchro rings on to gear cones and measure gap "a" with feelers.

Mod: |

|

|

|

→ Fig.6 Heat the needle bearing inner race to about 120° C, place it on shaft and drive it fully home Fitting direction:

|

|

|

|

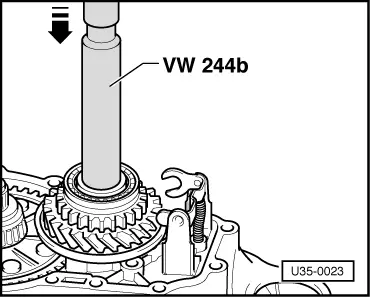

→ Fig.7 Drive needle bearing inner race fully home |

|

|

|

→ Fig.9 Installing stop bush Heat bush before installing -a- = 41 mm |

|

|

|

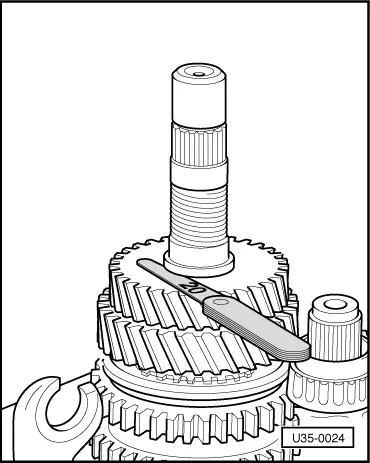

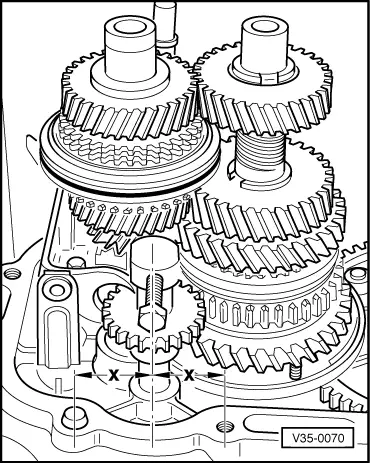

→ Fig.10 Aligning reverse gear shaft Dimensions x should be the same. |

|

|

|

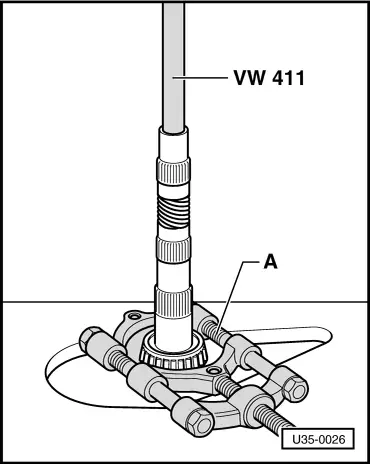

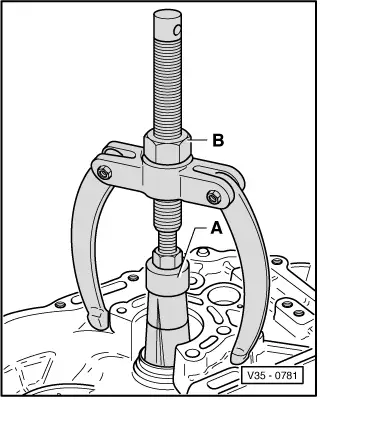

→ Fig.11 Pressing off inner race of large bearing A - Parting appliance such as Kukko 17/2 - 22 to 115 mm. Bearing is destroyed in the process. |

|

|

|

→ Fig.12 Pressing off inner race of small bearing A - Parting appliance such as Kukko 17/2 - 22 to 115 mm. Bearing is destroyed in the process. |

|

|

|

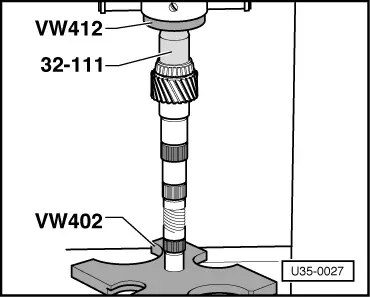

→ Fig.13 Heat inner race of small bearing to about 100 °C, fit on shaft and press home |

|

|

|

→ Fig.14 Heat inner race of large bearing to about 100° C, fit on shaft and press home |

|

|

|

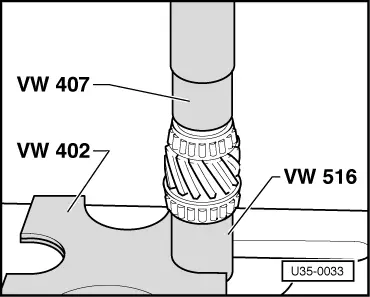

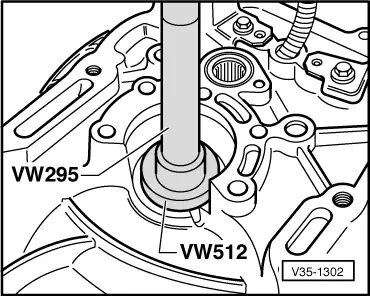

→ Fig.15 Pulling outer race of output shaft out

|

|

|

|

→ Fig.16 Knocking in outer race of small bearing |

|

|

|

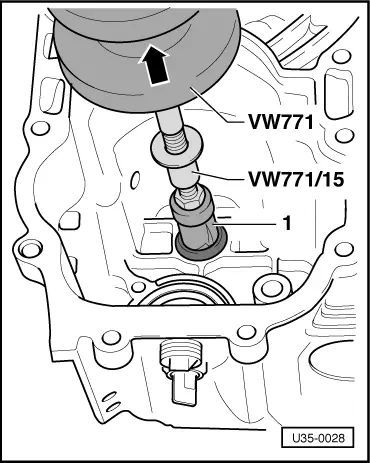

→ Fig.17 Removing output shaft needle bearing

|

|

|

|

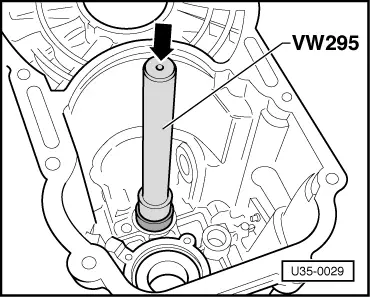

→ Fig.18 Knocking in output shaft needle bearing |