Golf Mk1

|

Dismantling and assembling input shaft

Adjusting output shaft

|

|

|

|

(Finding thickness of "S3" shim) The output shaft must be adjusted if See also "Adjustment list" =>page 39-20

|

|

||||||||||||||||

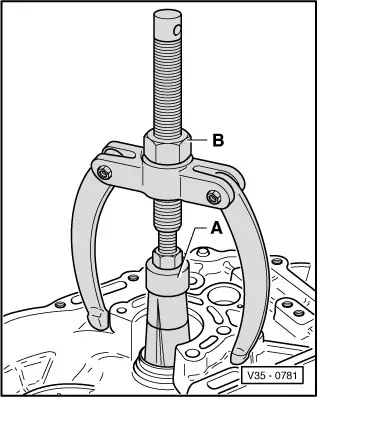

A - Shim 0.65 mm thick.

Caution

Do not turn the shaft when measuring because the bearings will then settle and give an incorrect reading. Finding thickness of S3 shim The specified bearing preload is obtained by adding a constant figure (0.20 mm) to the measured reading (0.30 mm) and the shim thickness (0.65 mm) for S3.

| ||||||||||||||||

|

||||||||||||||||||||||||||||||||||

The following shims are available:

Different tolerances make it possible to select exactly the required shim thickness. |

|

|

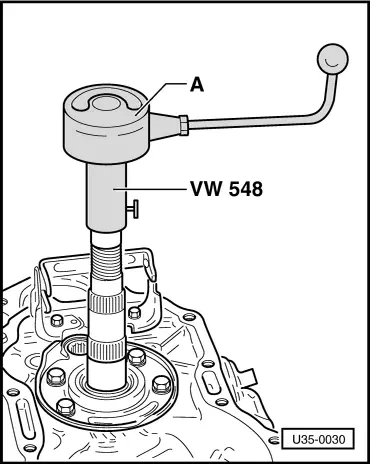

→ A = Torque gauge 0-600 Ncm Checking turning torque This should be 50 - 150 Ncm for new bearings. The turning torque on bearings which have been in use should be at last 30 Ncm. Lubricate bearings beforehand with hypoid gear oil. |