Golf Mk1

|

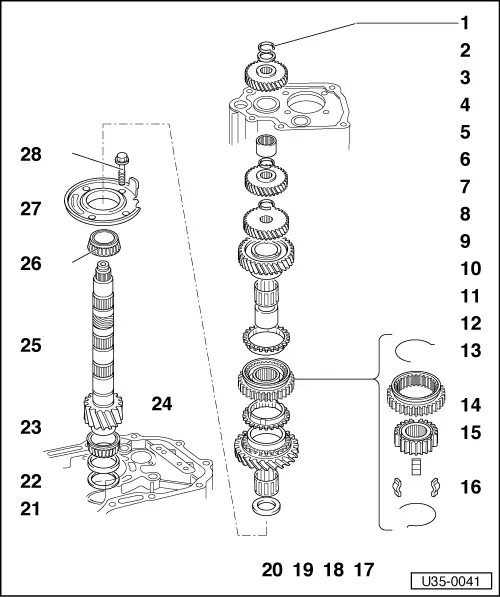

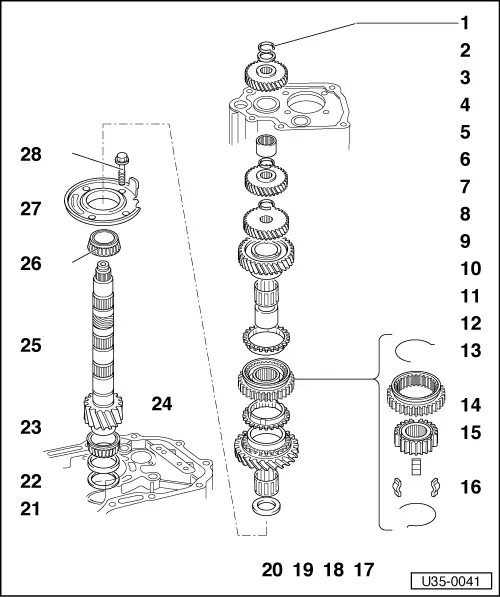

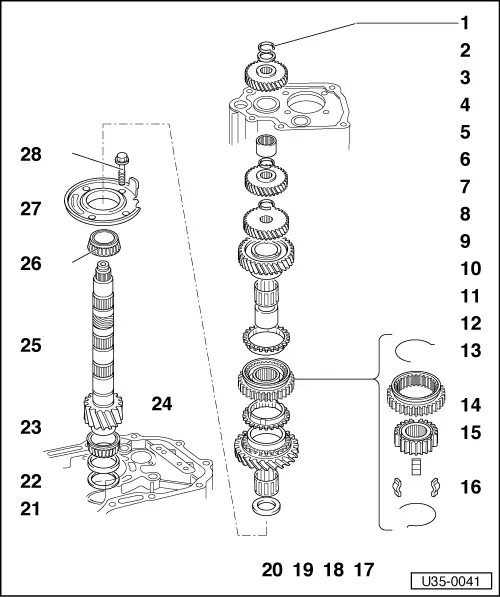

Gears, Shafts

Dismantling and assembling output shaft

|

|

|

|

Note:

Additional bearing for output shaft

Pinion shaft |

|

|

|

|

|

|

|

|

|

|||||||

|

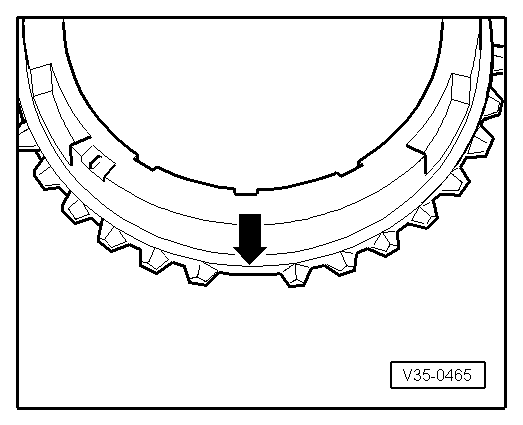

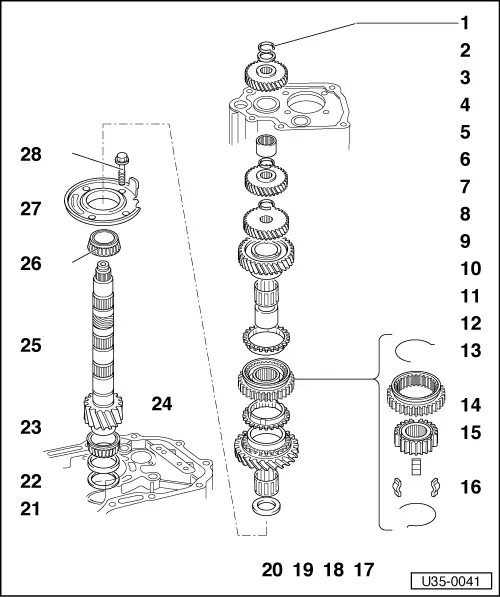

→ Fig.1 Checking synchronizer rings Press synchro rings on to gear cones and measure gap "a" with feelers.

|

|

|

|

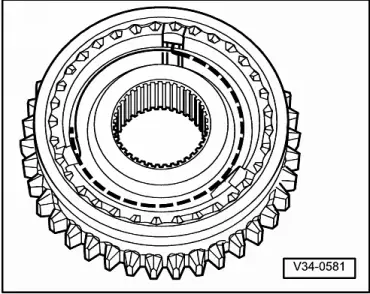

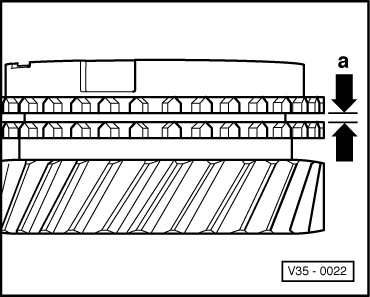

→ Fig.3 Assembling hub and sleeve for 1st and 2nd gear Fitting position: |

|

|

|

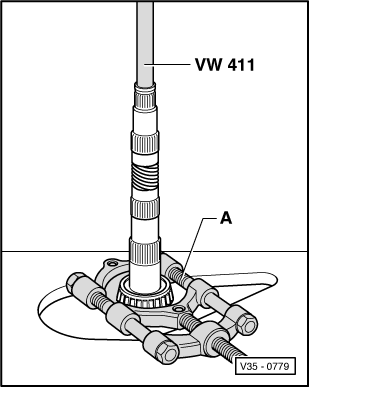

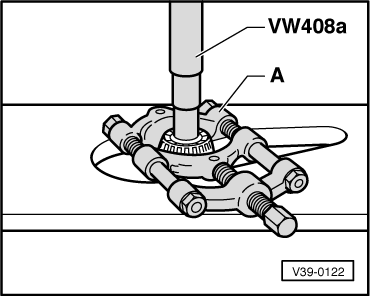

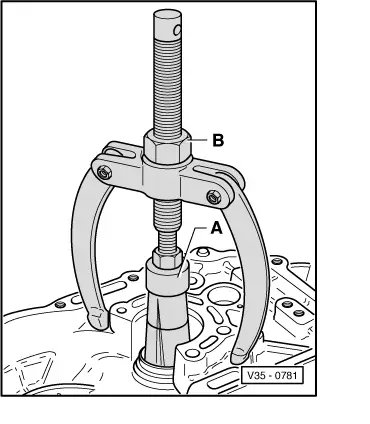

→ Fig.5 Pressing off inner race of large bearing A - Parting appliance such as kukko 17/2 - 22 to 115 mm. Bearing is destroyed in the process. |

|

|

|

→ Fig.6 Pressing off inner race of small bearing A - Parting appliance such as kukko 17/2 - 22 to 115 mm. Bearing is destroyed in the process. |

|

|

|

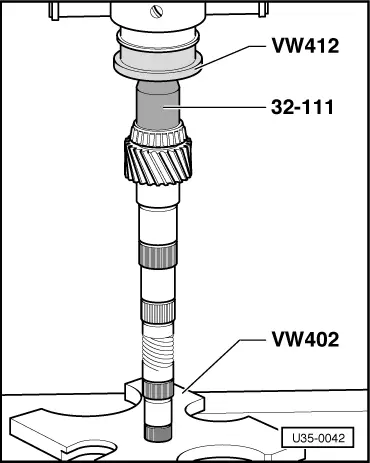

→ Fig.7 Heat inner race of small bearing to about 100° C, fit on shaft and press home |

|

|

|

→ Fig.8 Heat inner race of large bearing to about 100° C, fit on shaft and press home |

|

|

|

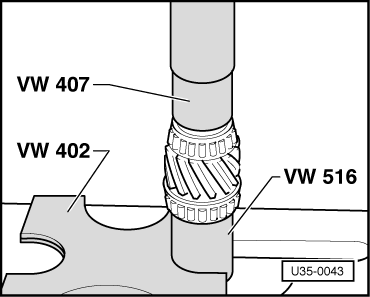

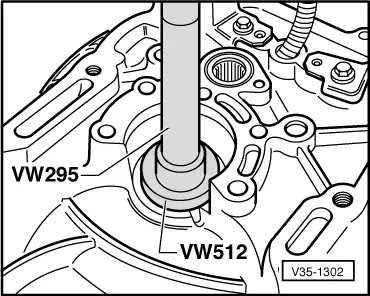

→ Fig.9 Pulling outer race of small bearing out of bearing housing

|

|

|

|

→ Fig.10 Knocking outer race of small bearing into bearing housing |

|

|

|

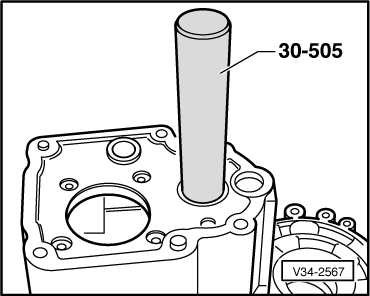

→ Fig.11 Knocking needle bearing out of gearbox housing |

|

|

|

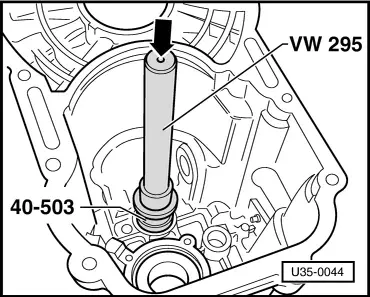

→ Fig.12 Knocking needle bearing into gearbox housing |