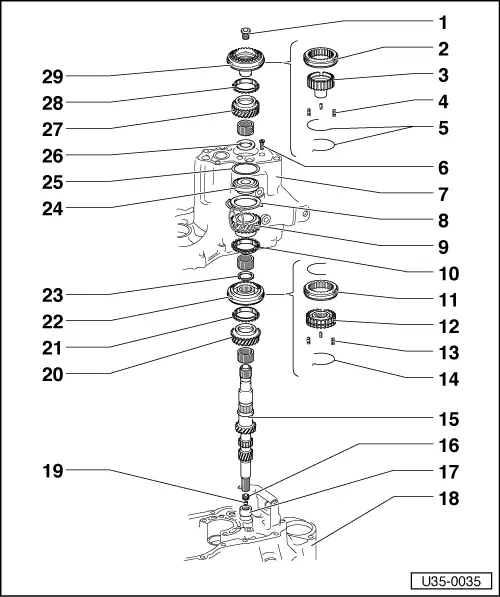

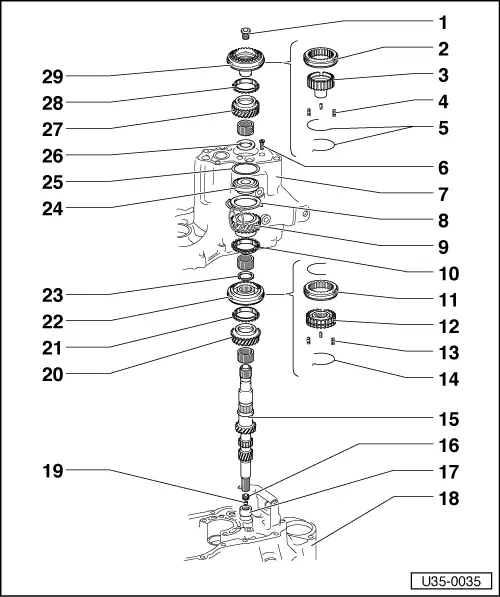

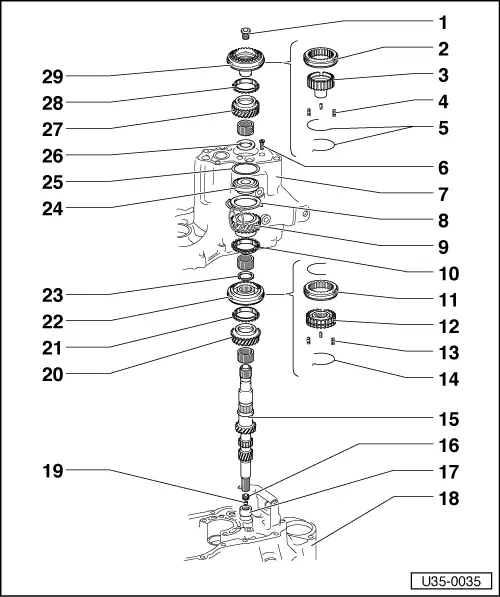

Golf Mk1 Transmission: Dismantling and assembling input shaft

|

Gears, Shafts

Dismantling and assembling input shaft

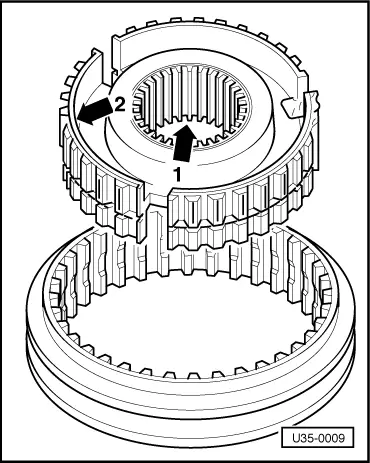

Synchronizer hub for 5th gear with retaining ring for locking keys =>page 35-36 Note: When installing new gears, see Technical Data

|

|

|

|

|

|

|

|

|

|

|

|

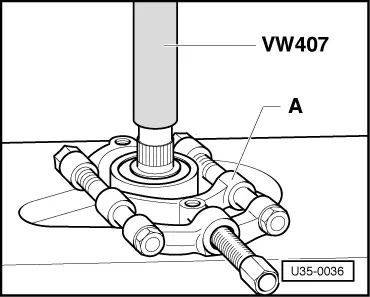

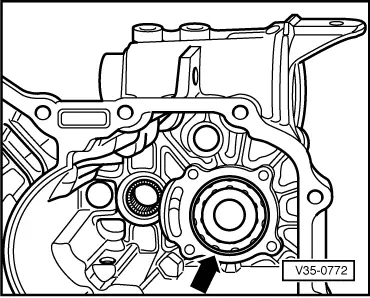

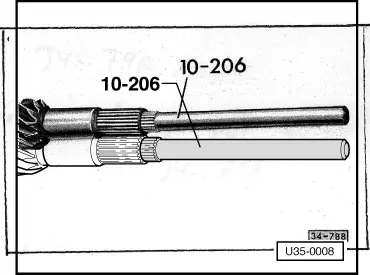

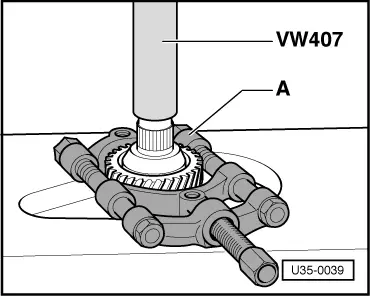

→ Fig.1 Pressing ball bearing off A - Separating appliance 12 - 75 mm - e.g. Kukko 17/1. |

|

|

|

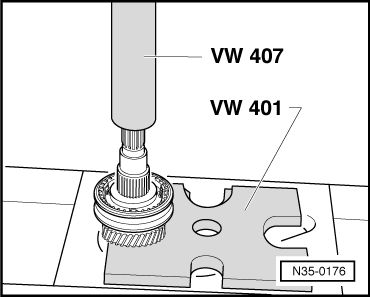

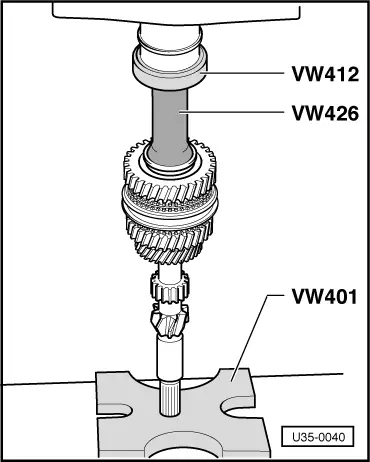

→ Fig.2 Pressing off sleeve/hub with 3rd speed gear |

|

||||||||||

|

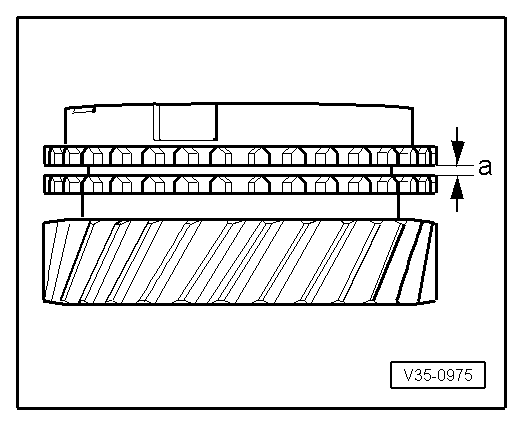

→ Fig.3 Checking synchronizer rings Press synchro ring on to gear cone and measure gap "a" with feelers

|

|

|

|

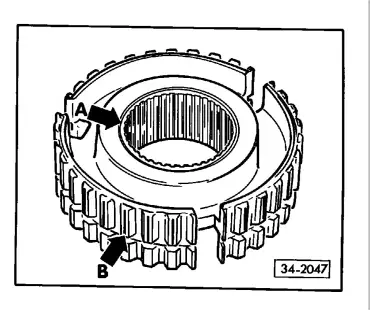

→ Fig.5 Identification of hub for 3rd/4th gear Either a groove -withe arrow- on hub (4th gear side) or axial grooves or the splines -black arrow-. |

|

|

|

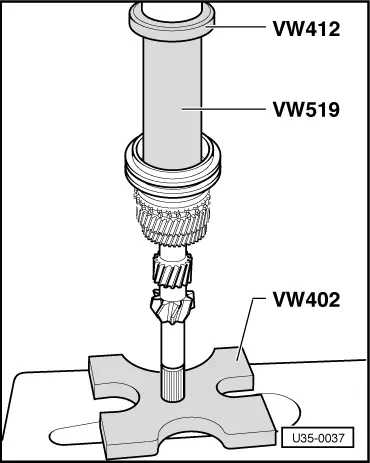

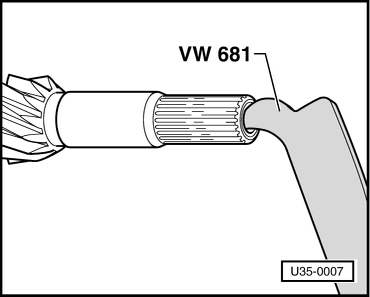

→ Fig.7 Pressing hub and sleeve on Fitting direction: Turn synchronizer ring so that grooves align with keys. |

|

|

|

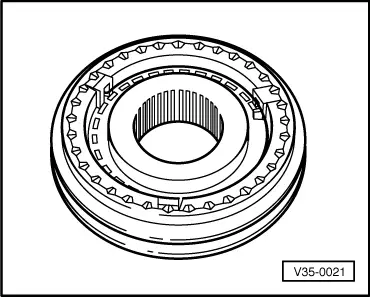

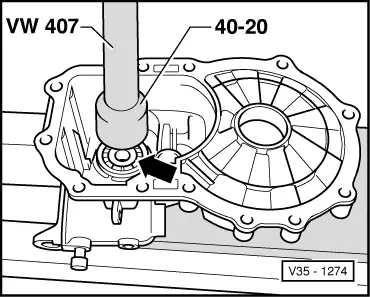

→ Fig.8 Pressing ball bearing and shim into the gearbox housing Fitting direction: Secure with clamping plate =>fig. 9 . |

|

|

|

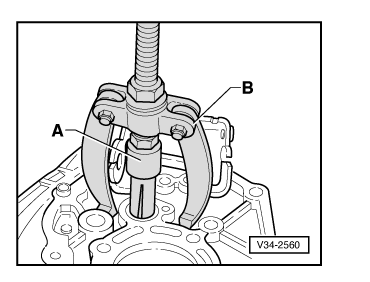

→ Fig.9 Securing clamping plate |

|

|

|

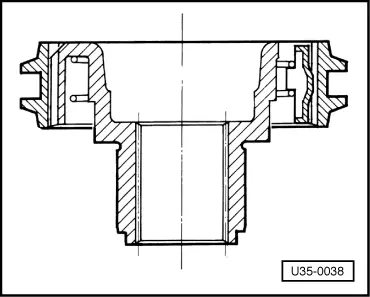

→ Fig.10 Position of seal and bush

|

|

|

|

→ Fig.11 Pulling seal for clutch push rod out Can be removed with gearbox out without dismantling box |

|

|

|

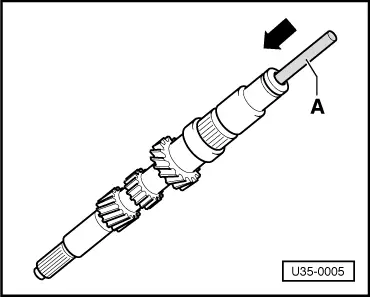

→ Fig.12 Knocking out bush for clutch push rod A = 10 mm rod such as an old pump shaft from automatic gearbox. |

|

|

|

→ Fig.13 Drive bush in fully |

|

|

|

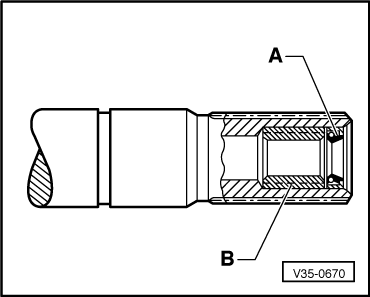

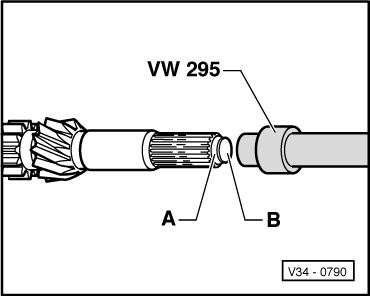

→ Fig.14 Installing seal Push seal -A- in with the fitting plug -B- supplied. Take plug out. The seal is then in the correct position. (0.8 - 1.3 mm deep). Oil lips of seal. |

|

|

|

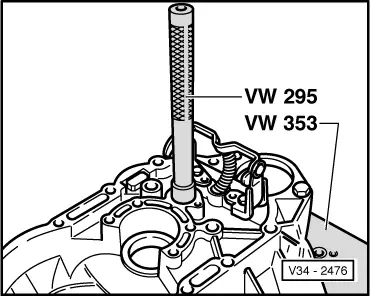

→ Fig.16 Pulling needle bearing out of bearing housing

|

|

|

|

→ Fig.17 Knocking needle bearing into bearing housing |

|

|

|

→ Fig.18 Pressing off 4th speed gear and ball bearing inner racer

Only up to assembly date 31 059 |

|

|

|

→ Fig.19 Pressing on ball bearing inner race Only up to assembly date 31 05 9. |