Golf Mk1

|

|

Switch ignition.

Should LED fail to light up:

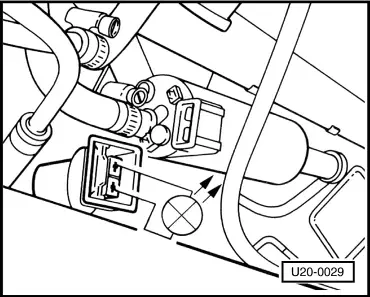

b) Fuel pump (Installation location: underside of vehicle just forward of right side rear axle mounting) |

|

|

Switch ignition.

Should LED fail to light up:

Testing fuel pump delivery capacity and check valve

A - Checking delivery capacity

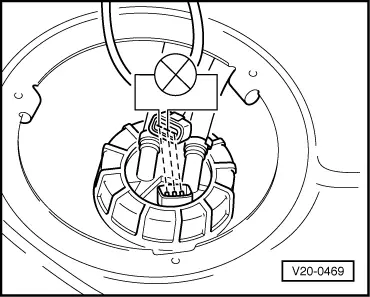

Lift pump

|

|

|

Fuel pump

|

|

|

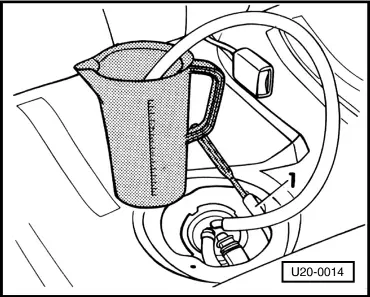

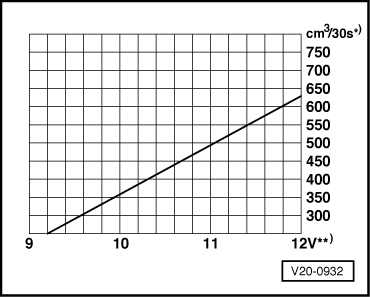

*) Minimum delivery cm3/30 seconds **) Voltage at fuel pump with engine stationary and pump running (approx. 2 volts less than battery voltage). Note: Should specified quantity not be achieved:

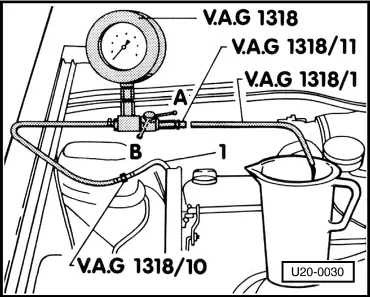

B- Testing check valve Note: In this test the fuel supply pipe connections between fuel pump and the connection of the pressure gauge V.A.G 1318 are also tested for leaks.

Important!

The valve of the pressure gauge must be closed for the pressure test (lever at right angle to direction of flow - Position B). Switch on ignition.

Important!

Danger of spray when valve is opened container should be held in front of free connection of pressure gauge.

Where indicated, check fuel system connections for leaks and/or renew fuel pump. |