Golf Mk2

| Repairing drive shaft |

Note

Note| t | Grease filling high-temperature grease -G 052 133 A2-: Outer CV joint: 90 g, inner CV joint: 120 g |

| t | Greasing outer joint: press half of the grease into the joint and the other half evenly into the bellows. |

| t | Greasing inner joint: Press half of the grease into the joint from both sides, the other half evenly into the bellows. |

| t | Regrease joint if required when renewing boot. |

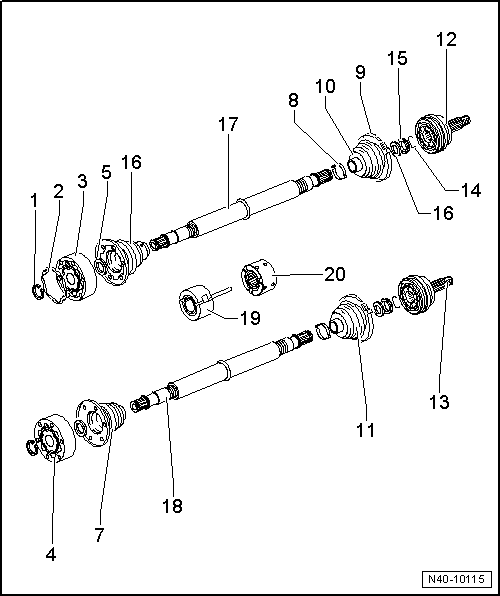

| 1 - | Retaining ring |

| q | Renew. |

| q | Expand and compress with circlip pliers -VW 161 A-. |

| 2 - | Gasket |

| q | Renewing. Pull off protective foil and stick into joint. |

| q | Only on 100 mm Ø constant velocity joints. |

| 3 - | Inner constant velocity joint Ø 100 mm |

| q | For vehicles with output of 66 kW and above. |

| q | Different material for 16V vehicles. |

| q | Renew only complete. |

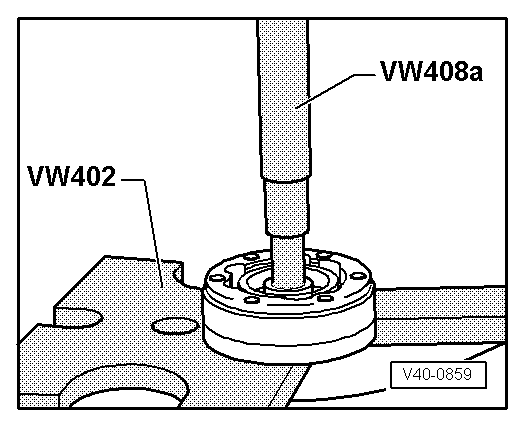

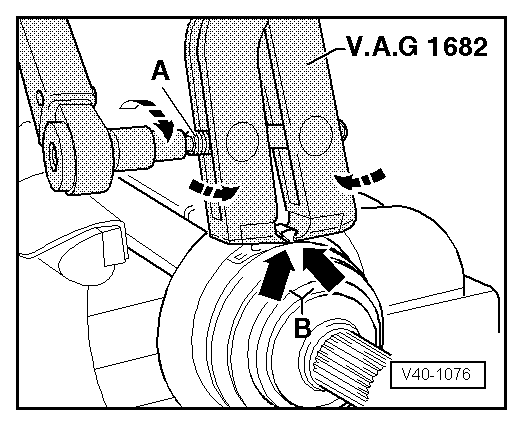

| q | Pressing off → Fig.. |

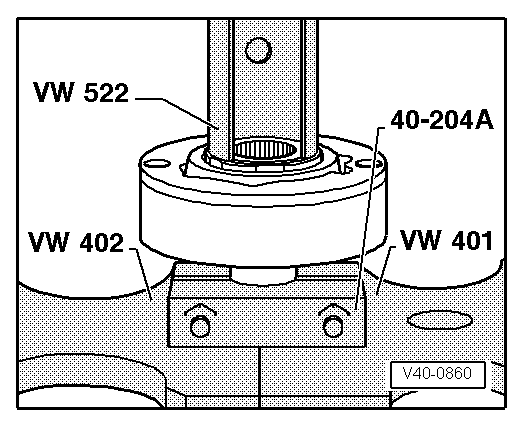

| q | Pressing on → Fig.. |

| q | Greasing → Chapter |

| q | Checking → Chapter |

| q | As of 08.89 also for vehicles over 62 kW. |

| 4 - | Inner constant velocity joint Ø 94 mm |

| q | For vehicles with output up to 65 kW. |

| q | Renew only complete. |

| q | Pressing off → Fig.. |

| q | Pressing on → Fig.. |

| q | Greasing → Chapter |

| q | Checking → Chapter |

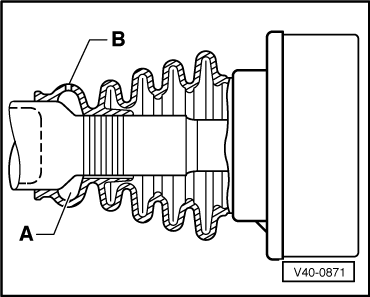

| 5 - | Dished spring |

| q | Toothed in inner Ø |

| q | Installation position: larger Ø (concave side) contacts constant velocity joint. |

| 6 - | CV joint boot for 100 mm Ø CV joint |

| q | With vent hole |

| q | Check for splits and chafing. |

| q | Installation position for left shaft → Fig. |

| q | Installation position for right shaft → Fig.. |

| q | Coat cap sealing surface with sealant -D 454 300 A2-. |

| q | Drive off with drift. |

| 7 - | CV joint boot for 94 mm Ø CV joint |

| q | Check for splits and chafing. |

| q | Drive off with drift. |

| 8 - | Clamp |

| q | Renew. |

| q | Tensioning → Fig. and → Fig.. |

| 9 - | Hose clip |

| q | Renew, separate closed metal rings with metal saw. |

| q | Tensioning → Fig. and → Fig.. |

| q | Modified as of 01.90 → Fig.. |

| 10 - | CV joint boot for 90 mm Ø CV joint |

| q | Check for splits and chafing. |

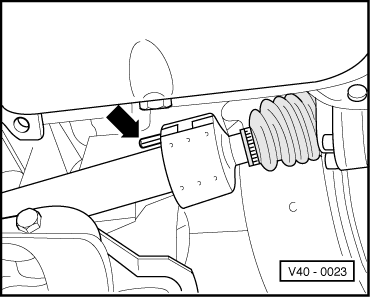

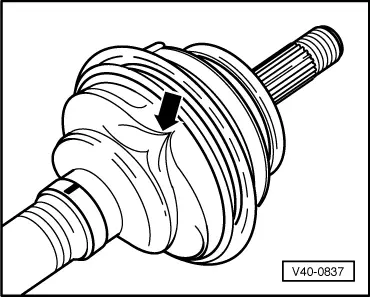

| q | Allow air to enter joint protective boot briefly to balance pressure before tightening small clamp in place → Fig.. |

| 11 - | CV joint boot for 81 mm Ø CV joint |

| q | Check for splits and chafing. |

| q | Allow air to enter joint protective boot briefly to balance pressure before tightening small clamp in place → Fig.. |

| q | Modified as of 01.90 → Fig.. |

| 12 - | Outer constant velocity joint Ø 90 mm |

| q | For vehicles with output of 66 kW and above. |

| q | Different material for 16V vehicles. |

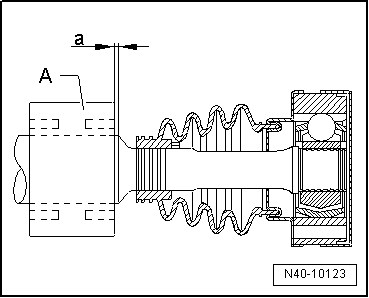

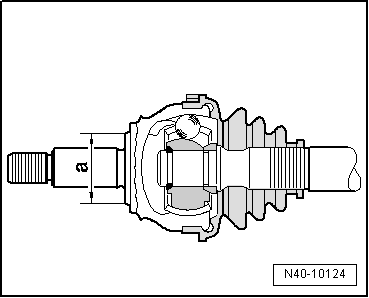

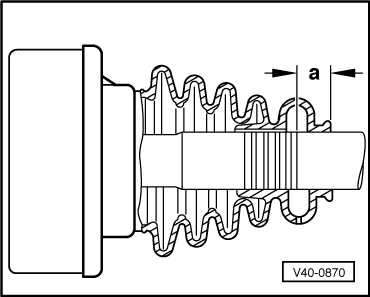

| q | Modification: As of 08.87 contact shoulder for wheel bearing modified → Fig.. |

| q | Renew only complete. |

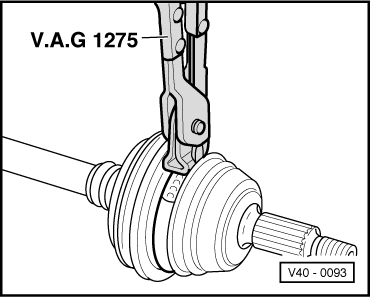

| q | Removing → Fig. |

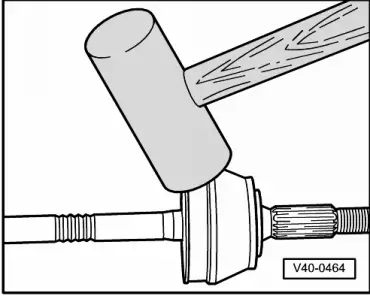

| q | Installing: drive onto shaft with plastic hammer until compressed circlip seats |

| q | Greasing → Chapter |

| q | Checking → Chapter |

| 13 - | Outer constant velocity joint Ø 81 mm |

| q | For vehicles with output up to 65 kW. |

| q | Modification: As of 08.87 contact shoulder for wheel bearing modified → Fig.. |

| q | Renew only complete. |

| q | Removing → Fig. |

| q | Installing: drive onto shaft with plastic hammer until compressed circlip seats |

| q | Greasing → Chapter |

| q | Checking → Chapter |

| 14 - | Retaining ring |

| q | Renew. |

| q | Insert in groove in shaft. |

| 15 - | Thrust washer |

| 16 - | Dished spring |

| q | Outer Ø (concave side) contacts thrust washer. |

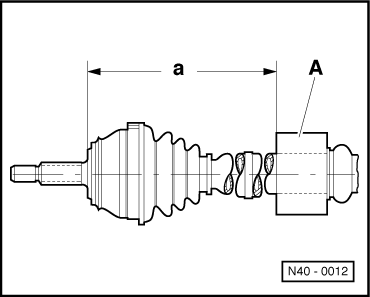

| 17 - | Drive shaft for vehicles with output of 66 kW and above |

| q | Constant velocity joint splines 4 mm longer than shafts for lower-output engines, measured from dished spring support to retaining ring groove. |

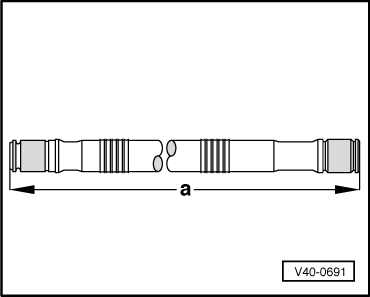

| q | Length of shaft → Fig.. |

| q | As of 08.89 also installed in vehicles over 62 kW. |

| 18 - | Drive shaft for vehicles with output up to 65 kW |

| q | Length of shaft → Fig.. |

| q | As of 08.89 also installed in vehicles up to 59 kW. |

| 19 - | Damper weight (two-piece) |

| q | Installed on right shaft in vehicles with 51 kW engines and vehicles with diesel engine. |

| q | Removing and installing → Fig. |

| q | Installation position → Fig.. |

| 20 - | Damper weight (one-piece) |

| q | Installed as of 04.88 (standard). |

| q | Use damper weight → Item as spare part. |

| q | Installation position → Fig.. |

Note

Note

|

|

Note

Note

|

|

|

|

| As of 08.87 | Dimension a = Ø 53 mm |

| Up to 08.87 | Dimension a = Ø 50 mm |

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

| Gearbox version | Length dimension -a- (mm) | Remarks | |||

| Left | Right | ||||

| Manual gearbox 020 → Note and 02A | 443 | 677.2 | Left full shaft right tubular shaft | ||

| Manual gearbox 084 and 085 | 465 | 677.2 | Left full shaft right tubular shaft | ||

| Automatic gearbox | 443 | 677.2 | Left full shaft right tubular shaft | ||

| Golf syncro manual gearbox 009 and 02C front axle, rear axle | 443 543.6 | 513.5 404.5 | Left/right full shaft left/right full shaft | ||

|