Golf Mk2

| Golf Country - removing and installing spacer frame |

Note

Note| t | All threads of bolts, nuts, washers and contact surfaces of spacer frame must be free of underbody sealant, wax or contamination. |

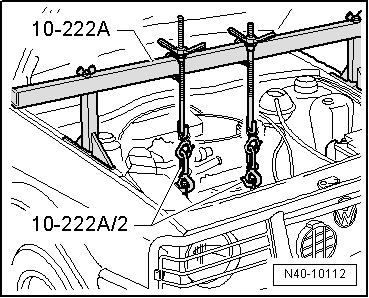

| t | To remove, first support engine/gearbox assembly → Fig.. |

| t | Removing and installing exhaust system → 4-cylinder injection engine (2-valve), mechanical system; Rep. Gr.26. |

| t | Renew self-locking nuts. |

| 1 - | Twelve point bolt, 45 Nm |

| 2 - | Bolt, 40 Nm |

| 3 - | Hexagon bolt, 25 Nm |

| q | Intermediate bearing to spacer frame. |

| 4 - | Propshaft |

| q | When removing and installing propshaft, ensure that centring sleeve in flange is not damaged → 5-speed manual gearbox 009, four-wheel drive; Rep. Gr.39. |

| q | Push rear propshaft tube forwards as far as possible in direction of travel. |

| q | Unbolt front and rear intermediate bearings; when lowering propshaft, ensure it is not kinked; use a second mechanic if necessary. |

| 5 - | Hexagon bolt M12×1.5 x 30 |

| 6 - | Washer, reinforced |

| 7 - | Self-locking nut, 75 Nm |

| q | With captive washer |

| 8 - | Strut - towing attachment |

| 9 - | Underride guard for final drive |

| 10 - | Strut - underride guard |

| 11 - | Hexagon bolt, M12×45 |

| 12 - | Hexagon bolt M8x16 |

| 13 - | Rear right cover |

| 14 - | Rear left cover |

| 15 - | Hexagon bolt M12×1.5 x 180 |

| q | Renew bolt |

| q | Tightening sequence: |

| q | Tighten bolt to 60 Nm. |

| q | Continue turning bolt 240° without stopping (if necessary, use ratchet with attached pipe, approx. 600 mm long or correspondingly long torque wrench, e.g. -V.A.G 1576-). |

Note

Note| Use of a socket insert with hexagon flats is recommended (increased protection against slipping). |

| 16 - | Hexagon bolt M12×1.5 x 188 |

| q | Renew bolt |

| q | Tightening sequence: |

| q | Tighten bolt to 60 Nm. |

| q | Continue turning bolt 180° without stopping (if necessary, use ratchet with attached pipe, approx. 600 mm long or correspondingly long torque wrench, e.g. -V.A.G 1576-). |

Note

Note| Use of a socket insert with hexagon flats is recommended (increased protection against slipping). |

| 17 - | Hexagon bolt M10 x 135, 50 Nm |

| 18 - | Hexagon bolt M12×1.5 x 192, 170 Nm |

| 19 - | Spacers |

| 20 - | Spacer frame |

| q | To remove, support engine/gearbox assembly → Fig.. |

| 21 - | Rear axle and differential |

| q | Removing and installing → Chapter |

| 22 - | Hexagon bolt, 45 Nm |

| 23 - | Hexagon bolt, 65 Nm |

| 24 - | Spring washer |

| q | Renew. |

| 25 - | Gearbox carrier |

| q | Renewing bonded rubber bush → Fig. |

| 26 - | Hexagon bolt, 85 Nm |

| 27 - | Mounting bracket |

| q | 120 mm longer than in Golf syncro. |

| 28 - | Hexagon bolt, 85 Nm |

| 29 - | Mounting bracket |

| q | Mark installation position before removing, otherwise rear axle must be aligned on a wheel alignment unit. |

| 30 - | Self-locking nut, 30 Nm |

| q | Renew. |

| 31 - | Heat shield |

| 32 - | Sealing boot |

| q | Extended approx. 120 mm. |

| q | Universal joint shaft has also been extended by 120 mm. |

|

|