Golf Mk3

Note

Note

|

| 1 - | Gearbox housing |

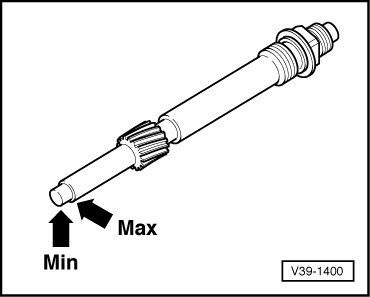

| 2 - | Speedometer drive |

| q | With marking for indicating oil level → Fig. |

| 3 - | Output shaft for drive flange |

| q | Install with thread facing drive flange |

| q | Remove before removing differential |

| q | Install only after adjusting differential |

| 4 - | O-ring |

| q | Always renew |

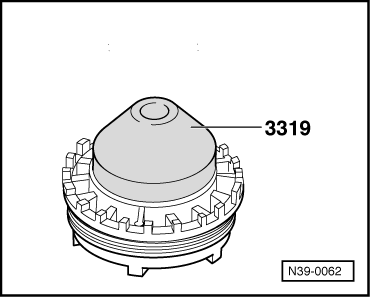

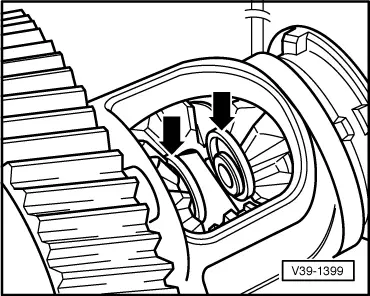

| 5 - | Adjusting ring |

| q | Removing → Fig. |

| q | If used bearings are to be refitted, mark installation position before removal and reinstall in marked position → Fig. |

| q | When installing new bearings, pay attention to adjustment instructions ⇒ Adjusting differential, → Chapter |

| 6 - | Drive flange oil seal |

| q | Before installing, pack space between sealing lips with multi-purpose grease |

| q | Can be renewed with gearbox installed → Chapter |

| q | Remove with oil seal extractor lever -VW 681- |

| q | Driving in → Fig. |

| 7 - | Tapered ring |

| q | Shoulder faces thrust washer |

| 8 - | Thrust washer |

| q | Place over compression spring |

| 9 - | Compression spring |

| 10 - | Drive flange |

| q | Insert with tapered ring, thrust washer and compression spring |

| q | Remove before removing inner retaining ring on differential bevel gear |

| q | Removing and installing → Fig. |

| 11 - | Dished washer |

| 12 - | Retaining ring |

| 13 - | Sealing cover |

| 14 - | Locking element |

| 15 - | Bolt, 12 Nm |

| 16 - | Sealing cover |

| 17 - | Retaining ring |

| 18 - | Dished washer |

| 19 - | Drive flange |

| q | Insert with tapered ring, thrust washer and compression spring |

| q | Remove before removing inner retaining ring on differential bevel gear |

| q | Removing and installing → Fig. |

| 20 - | Compression spring |

| 21 - | Thrust washer |

| q | Place over compression spring |

| 22 - | Tapered ring |

| q | Shoulder faces thrust washer |

| 23 - | Drive flange oil seal |

| q | Before installing, pack space between sealing lips with sealing grease -G 052 128- |

| q | Can be renewed with gearbox installed → Chapter |

| q | Remove with oil seal extractor lever -VW 681- |

| q | Driving in → Fig. |

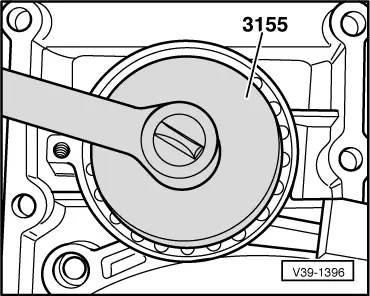

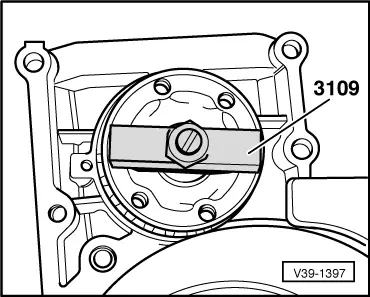

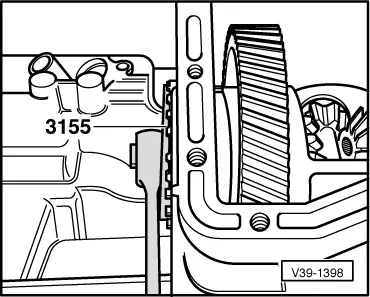

| 24 - | Bearing body, 150 Nm |

| q | When installing new bearings, pay attention to adjustment instructions ⇒ Adjusting differential, → Chapter |

| q | Remove using slotted nut wrench -3155- |

| q | Installing → Fig. |

| 25 - | O-ring |

| q | Always renew |

| 26 - | Output shaft for drive flange |

| q | Install with thread facing drive flange |

| q | Remove before removing differential |

| q | Install only after adjusting differential |

| 27 - | Differential |

| q | Dismantling and assembling → Chapter |

| q | Before removing differential, take out bearing body, adjusting ring and output shafts |

| 28 - | Bolt, 12 Nm |

| 29 - | Locking element |

| 30 - | Retaining ring |

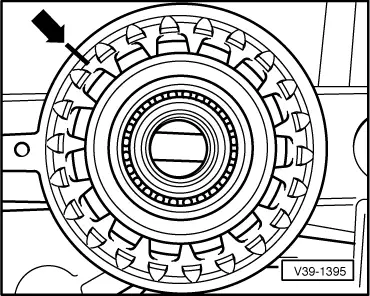

| q | First remove drive flange before removing retaining ring |

| q | Removing and installing → Fig. |

| 31 - | Retaining ring |

| q | First remove drive flange before removing retaining ring |

| q | Removing and installing → Fig. |

| 32 - | Seal |

| q | Always renew |

| 33 - | Cover |

| q | For differential |

| 34 - | Bolt, 28 Nm |

| q | Insert with locking fluid -AMV 185 101 A1- |

Note

Note| After adjusting tapered roller bearings, secure bearing body and adjusting ring. |

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|