Golf Mk3

| 1 - | Differential cage with riveted gear for final drive |

| q | Final drive gear is riveted onto differential housing and then machined |

| q | If the differential or final drive gear is damaged, replace the differential housing together with the riveted final drive gear |

| q | Number of teeth on final drive gear → Chapter |

| 2 - | Output shaft for drive flange |

| q | Removing and installing → Chapter |

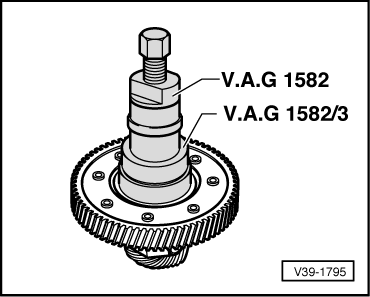

| 3 - | Tapered roller bearing inner race |

| q | Pulling off → Fig. |

| q | Press on as → Fig. |

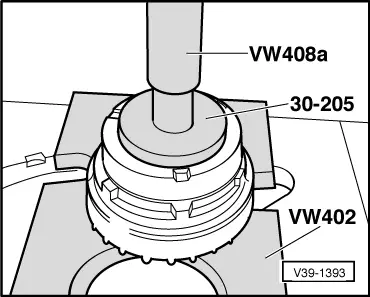

| 4 - | Tapered roller bearing outer race |

| q | Remove and install only with adjusting ring heated |

| q | Drive out with a drift |

| q | Pressing in → Fig. |

| 5 - | Bearing body for tapered roller bearing |

| q | Removing and installing differential → Chapter |

| 6 - | O-ring |

| q | Always renew |

| 7 - | O-ring |

| q | Always renew |

| 8 - | Adjusting ring for tapered roller bearing |

| q | Removing and installing differential → Chapter |

| 9 - | Output shaft for drive flange |

| q | Removing and installing differential → Chapter |

| 10 - | Tapered roller bearing outer race |

| q | Remove and install only with adjusting ring heated |

| q | Drive out with a drift |

| q | Pressing in → Fig. |

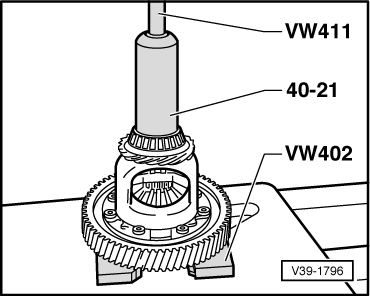

| 11 - | Tapered roller bearing inner race |

| q | Pulling off → Fig. |

| q | Pressing on → Fig. |

| 12 - | Drive bush |

| q | Drive off together with speedometer drive gear - → Item- |

| q | Drive on with drift |

| 13 - | Speedometer drive wheel |

| q | Drive out with a drift |

| q | Fit on together with drive bush - → Item- |

| 14 - | One-piece thrust washer |

| q | Place into differential housing before inserting bevel gears |

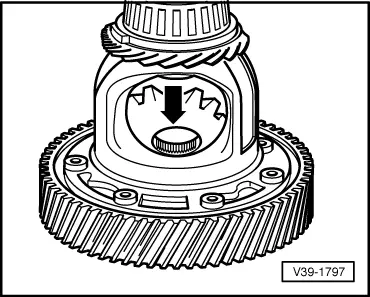

| 15 - | Planet pinions |

| q | Installing → Fig. |

| 16 - | Sun wheels |

| q | Installing → Fig. |

| 17 - | Retaining ring |

WARNING

WARNING

|

| 18 - | Differential pinion pin |

| q | Drive out with a drift |

| q | When driving in, do not damage one-piece thrust washer |

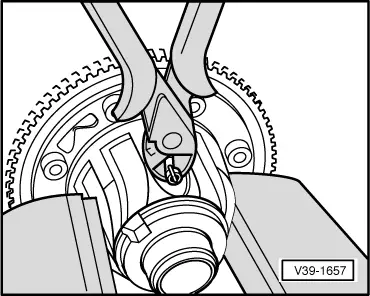

| 19 - | Spring pin |

| q | For securing differential pinion pin |

| q | Removing and installing spring pin with circumferential groove → Fig. |

|

|

|

|

|

|

|

|

|

|

Note

Note