-

‒ When lowering the assembly, ensure that clearance exists between assembly and drive shafts.

-

‒ →

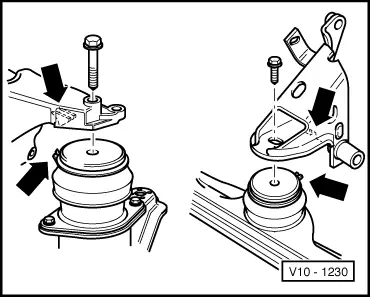

When installing the engine mounting ensure that the recess on the rear console and the recess on the front console locates on the lugs of the bonded rubber mounting -arrows-.

-

‒ Align engine mountings stress-free by rocking.

-

‒ Installing P.A.S. vane pump:

=> Running gear; Repair group 48; Assembly overview: vane pump, reservoir, hydraulic pipes; Removing and installing power assisted steering vane pump

-

‒ Install ribbed belt

.

-

‒ Install air conditioner compressor, vehicles with refrigerant R12:

=> Heating, air conditioning; Repair group 87; Refrigerant R12 air conditioning with manual control; Removing and installing compressor bracket - 4-cyl. petrol engine

-

‒ Install air conditioner compressor, vehicles with refrigerant R134a:

=> Heating, air conditioning; Repair group 87; Refrigerant R134a air conditioning with manual control; Removing and installing compressor bracket - 4-cyl. petrol engine

-

‒ Installing lock carrier with attachments:

=> General body repairs; Repair group 50; Body front; Servicing lock carrier with attachments

Engine codes ATU, AWF, AWG

-

‒ Installing lock carrier with attachments:

=> General body repairs, Convertible; Repair group 50; Body front; Servicing lock carrier with attachments

Continuation for all vehicles

-

‒ Install ribbed belt => Page 13-16

.

-

‒ Fill with coolant => Page 19-18

Vehicles with manual gearbox

=> 5-Speed manual gearbox 020; Repair group 30; Servicing clutch control; removing and installing clutch cable

-

‒ Adjust throttle cable => Page 20-10

-

‒ Electrical connections and routing:

=> Electrical system; Repair group 97

-

‒ Perform the work sequence "Procedure after interrupting voltage supply".

Engine codes AEK, AFT, AKS

-

‒ Carry out idling check:

=> Repair group 24; Simos injection and ignition system; idling check

=> Repair group 24; Motronic injection and ignition system; idling check

Engine codes ATU, AWF, AWG

=> Repair group 24; Engine control unit; Procedure after interrupting voltage supply.

-

‒ Read out readiness code:

=> Repair group 01; Readiness code; Reading out readiness code

-

‒ If the fault memory has been erased or the engine control unit separated from the permanent positive, the readiness code must be generated again.

=> Repair group 01; Readiness code; Generating readiness code

Continuation for all vehicles

-

‒ Carry out a test drive and interrogate fault memory:

=> Repair group 01; Self-diagnosis; Interrogating and erasing fault memory

-

‒ Check headlight adjustment and adjust if necessary:

=> Maintenance booklet

|