Golf Mk3

|

Removing and installing parts of the lubrication system

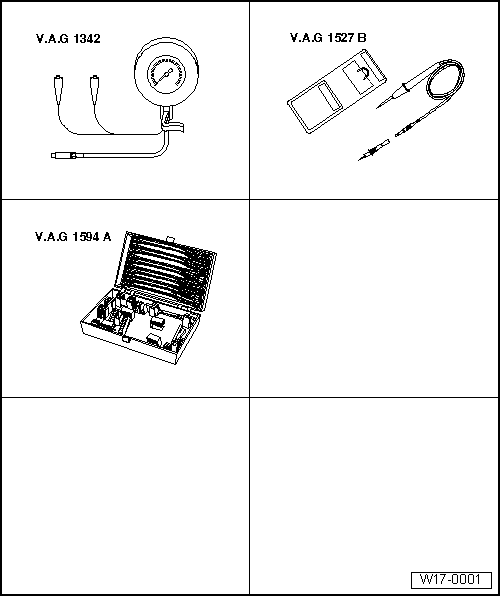

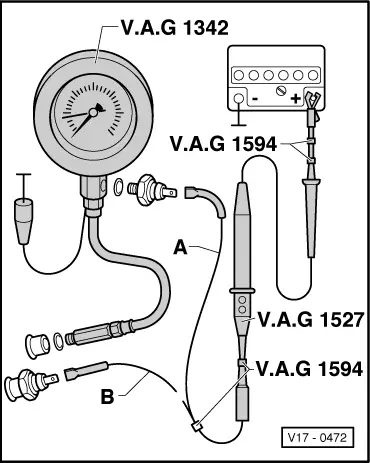

Checking oil pressure and oil pressure switch

|

|

|

|

Note: Functional check and servicing the optical and acoustic oil pressure warning: => Current flow diagrams, Electrical fault finding and Fitting locations Test sequence

Engine codes AEE, AEX, APQ: Test sequence |

|

|

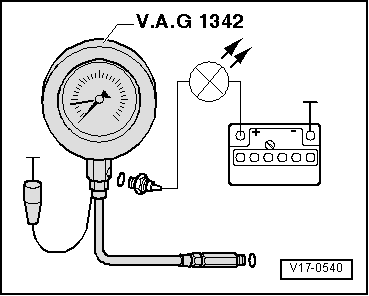

Vehicles 09.97 ▸ |

|

|

|

Note: Functional check and servicing the optical and acoustic oil pressure warning: => Current flow diagrams, Electrical fault finding and Fitting locations

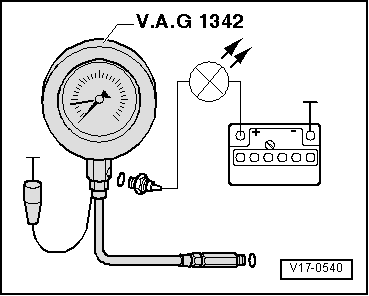

If the LED does not light up:

|