Golf Mk3

|

Removing and installing parts of the lubrication system

Removing and installing Duo-centric oil pump

|

|

|

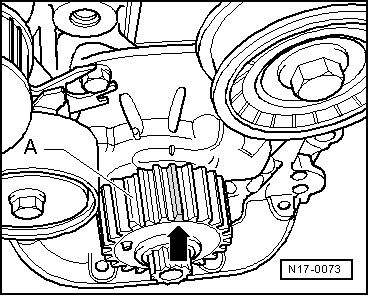

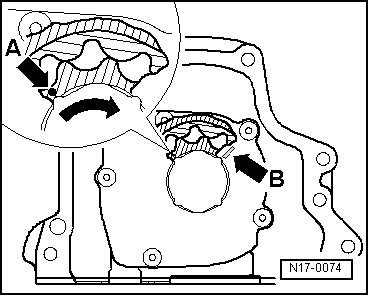

Note: This procedure moves the crankshaft to the correct installation position for the oil pump. One of the polygon cams on the crankshaft is uppermost.

|

|

|

|

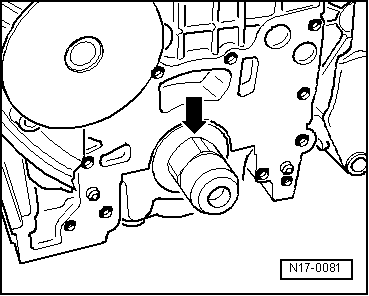

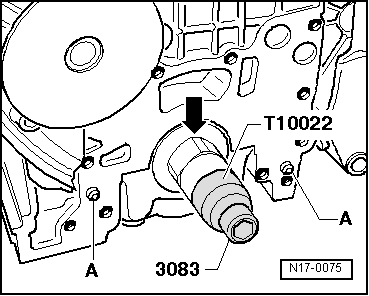

Installing Conditions

|

|

|

|

Work sequence

|

|

|

|