|

Removing and installing parts of the lubrication system

Removing and installing oil sump

Work sequence for engine with sump sealed with liquid gasket.

Special tools, workshop equipment, testers, measuring instruments and auxiliary items required

-

◆ Socket 3249

-

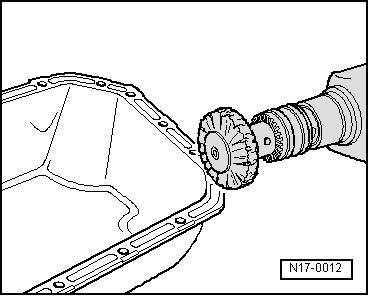

◆ Hand drill with plastic brush

-

◆ Flat scraper

Engine codes AEE, AEX:

-

◆ Silicone sealant D176404 A2

Work sequence

-

‒ Drain engine oil.

-

‒ Unbolt right-hand drive shaft at gearbox.

=> Running gear; Servicing front suspension (base running gear); Removing and installing wheel bearing, suspension strut and drive shaft (base running gear)

-

‒ Remove ribbed belt guard.

-

‒ Unbolt sump sealed with liquid gasket.

-

‒ Remove sump, it may be necessary to release sump by tapping lightly with a rubber head hammer.

-

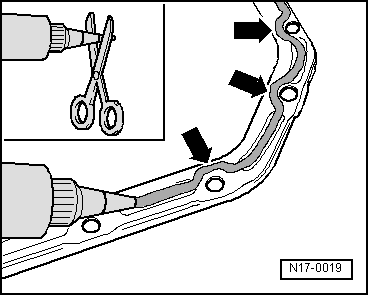

‒ Remove sealant residue on cylinder block with a flat scraper.

|