| t

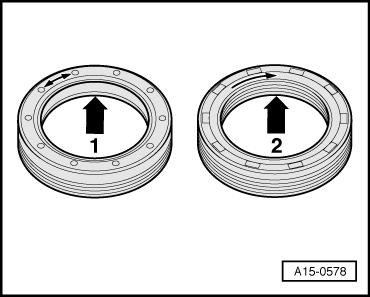

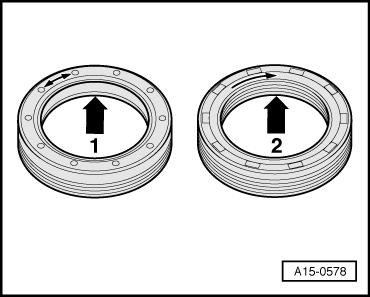

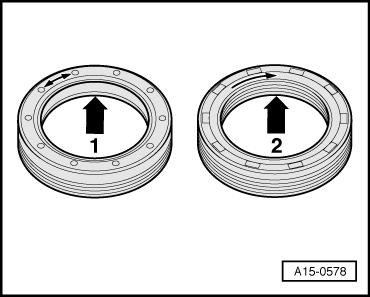

| A PTFE oil seal is being gradually introduced (Teflon) -2- in place of oil seal with internal circular spring -1-. This has a wider sealing lip. PTFE oil seals are installed free of oil and grease. |

| t

| An older design radial shaft seal (with coil spring) may be replaced by a PTFE seal, but not the other way around. |

| –

| Remove upper toothed belt guard. |

| –

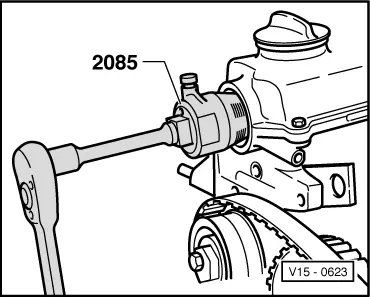

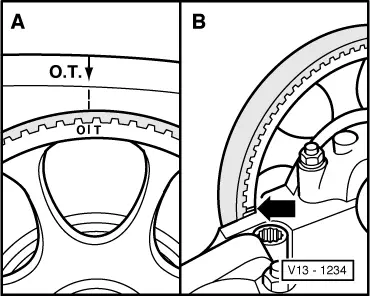

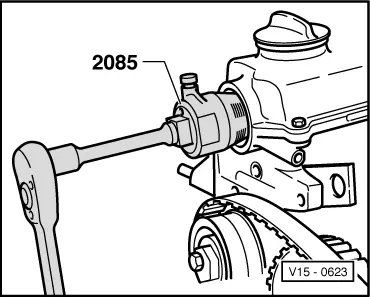

| Loosen camshaft pulley (using counterhold tool -3036-). |

| –

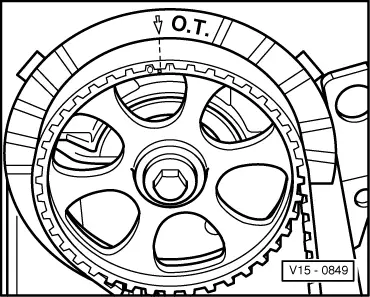

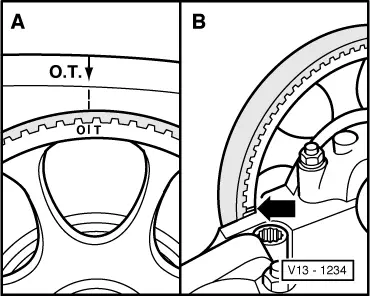

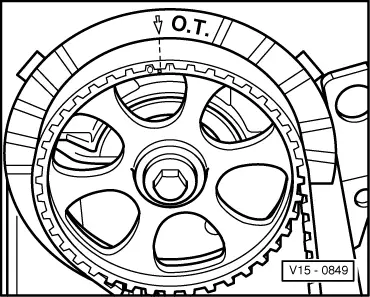

| Set camshaft pulley to TDC No. 1 cylinder by turning crankshaft. |

| Engine codes AAM, ABS, ADZ, ANN, ANP |

|

|

|

Note

Note

Note

Note