Golf Mk3

|

|

|

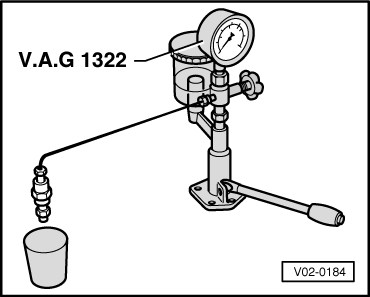

→ Checking opening pressure Warning!

When testing injectors ensure that the jet of fuel does not contact the hands as the high pressure will cause the fuel to penetrate the skin and may cause severe injuries. Engine code AAZ

Engine code 1Y

Note: When servicing used injectors adjust breaking pressures to specifications for new injectors.

Adjustment shims are available from 1.00...1.95 mm thick and increase by 0.5 mm. Use box 3065 to store shims. Checking for leaks

|