Golf Mk4

| Assembly overview - Repairing gearbox housing and clutch housing |

| Special tools and workshop equipment required |

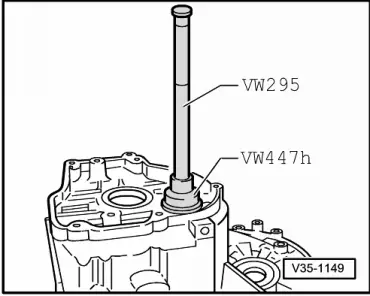

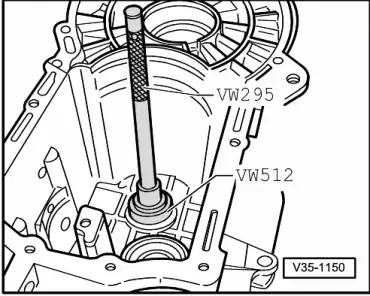

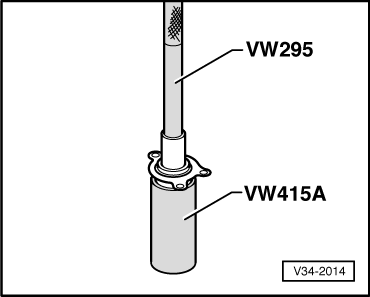

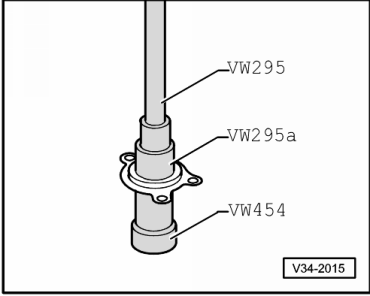

| t | Drift -VW 295- |

| t | Adapter -VW 295 A- |

| t | Thrust pad -VW 447 H- |

| t | Thrust pad -VW 512- |

| t | Tube -VW 415 A- |

| t | Thrust piece -VW 454- |

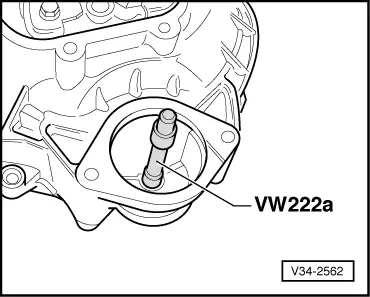

| t | Drift -VW 222 A- |

| t | Torque wrench -V.A.G 1331- |

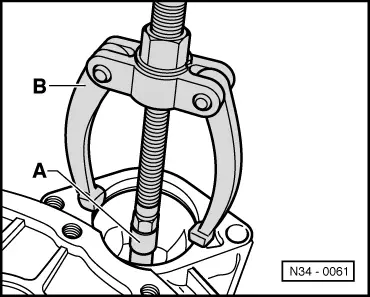

| t | Internal puller -1 - Kukko 22/1- |

| t | Counter support -4 - Kukko 22/1- |

| 1 - | Gearbox housing |

| q | If renewed: adjust input shaft and differential → Chapter |

| 2 - | Needle bearing |

| q | For output shaft |

| q | Removing → Fig. |

| q | Installing and securing → Fig.. |

| 3 - | Oil filler plug, 30 Nm |

| q | Without magnet |

| 4 - | Shim |

| q | For input shaft |

| q | Adjustment overview → Chapter |

| 5 - | Tapered roller bearing outer race |

| q | For input shaft |

| q | Pressing out → Fig. |

| q | Pressing in → Fig. |

| q | If renewed: adjust input shaft → Chapter |

| 6 - | Tapered roller bearing outer race |

| q | For output shaft |

| q | Removing and installing → Fig. |

| q | If replaced: Adjust output shaft → Chapter. |

| 7 - | Shim |

| q | For output shaft |

| q | Adjustment overview → Chapter |

| 8 - | Tapered roller bearing outer race |

| q | For input shaft |

| q | Removing and installing → Fig. |

| q | If renewed: adjust input shaft → Chapter |

| 9 - | Needle bearing |

| q | Removing and installing → Fig. |

| 10 - | Dowel sleeve |

| q | Qty. 2 |

| 11 - | Starter bush |

| q | Pulling out → Fig. |

| q | Driving in → Fig. |

| q | Can be renewed with gearbox installed. |

| 12 - | Clutch housing |

| q | When renewing: adjustment overview → Chapter |

| 13 - | Guide sleeve |

| q | With input shaft seal and vulcanised or bonded O-ring |

| q | Driving out oil seal → Fig.. |

| q | Driving in oil seal → Fig.. |

| q | Remove guide sleeve to change oil seal |

| q | If O-ring is damaged or has come loose, renew guide sleeve and O-ring together |

| 14 - | Socket head bolt, 20 Nm |

| q | Self-locking |

| q | Always renew |

| 15 - | Speedometer drive |

| q | Aluminium, tighten to 30 Nm |

| q | Plastic (polyamide), tighten to 10 Nm |

| 16 - | Oil drain plug, 30 Nm |

| q | Without magnet |

| 17 - | Tapered roller bearing outer race |

| q | For differential |

| q | Driving in and out → Item. |

| q | If renewed, adjust differential → Chapter |

| 18 - | Magnet |

| q | Held in place by housing joint surface |

| 19 - | Tapered roller bearing outer race |

| q | For differential |

| q | Driving in and out → Chapter. |

| q | If renewed, adjust differential → Chapter |

| 20 - | Shim |

| q | For differential |

| q | Adjustment overview → Chapter |

| 21 - | Seal |

| q | Renewing → Chapter |

|

|

|

|

|

|

|

|

|

|

|

|