Golf Mk4

| Procedure for removing and installing gearbox housing cover, gearbox housing, selector mechanism, input shaft, output shaft, differential and selector forks |

| Special tools and workshop equipment required |

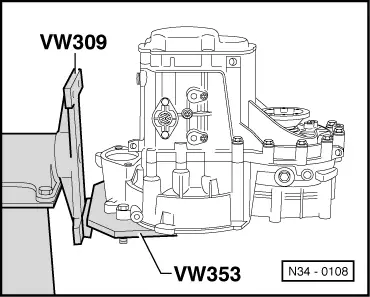

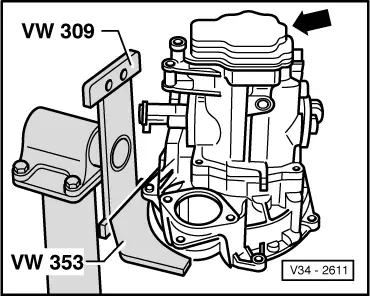

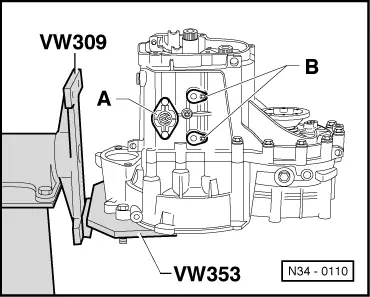

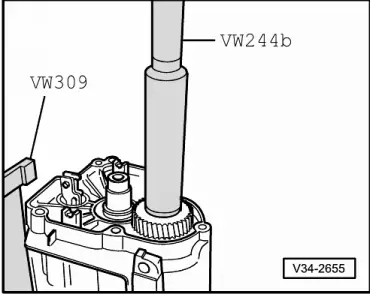

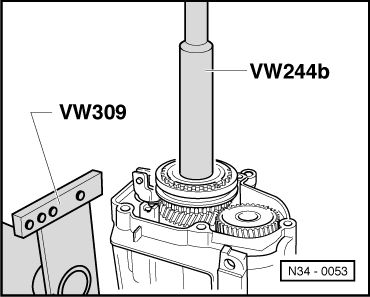

| t | Support plate -VW 309- |

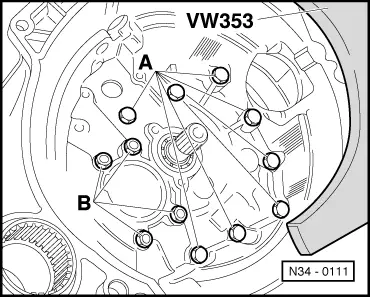

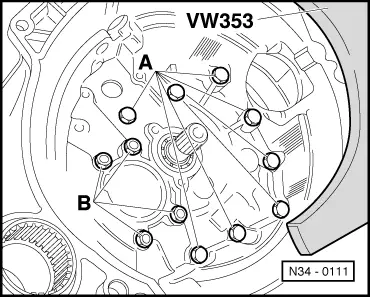

| t | Gearbox support -VW 353- |

| t | Drift -VW 295- |

| t | Drift sleeve -VW 244 B- |

| t | Hot air blower -V.A.G 1416- |

| t | Torque wrench -V.A.G 1331- |

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

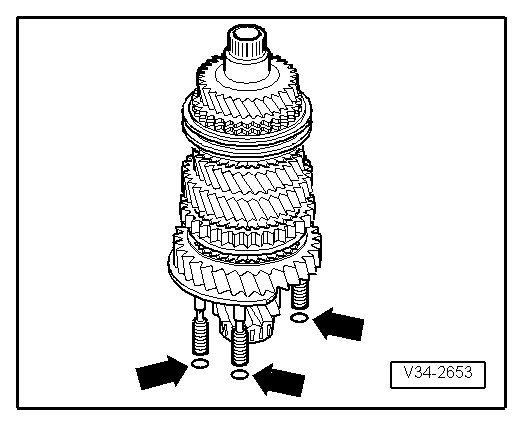

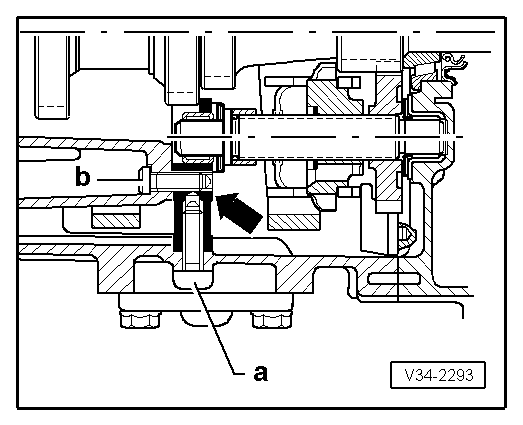

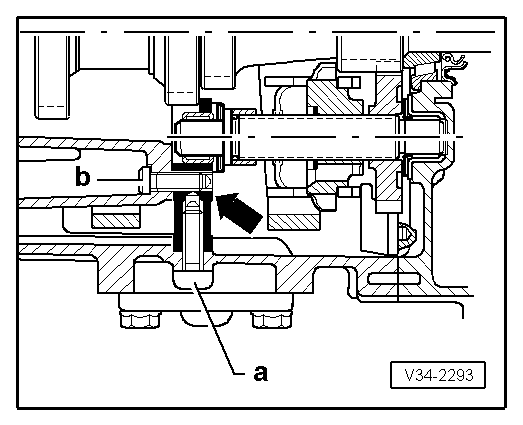

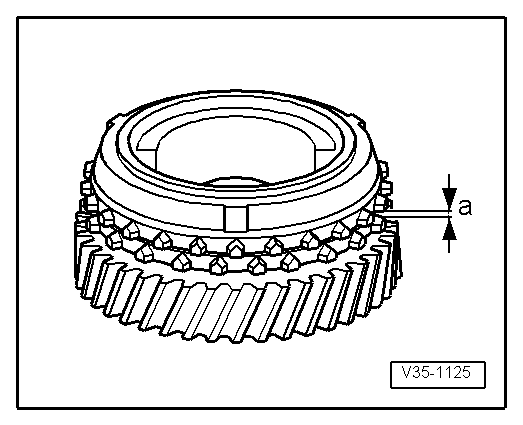

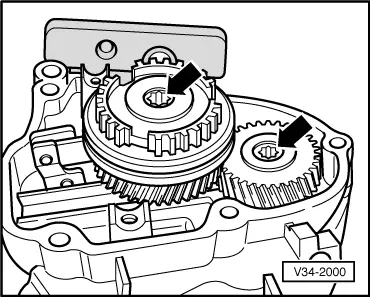

| Gap -a- | Installation (new) dimension | Wear limit |

| 5th gear | 1,1 ... 1.7 mm | 0.5 mm |

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|