Golf Mk4

| Adjusting differential |

| Special tools and workshop equipment required |

| t | Gearbox support -VW 353- |

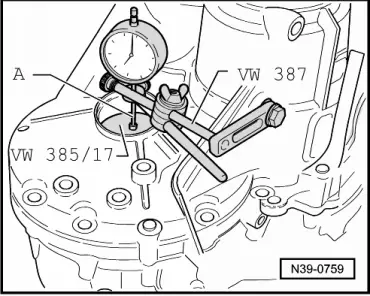

| t | End dimension plate -VW 385/17- |

| t | Universal dial gauge bracket -VW 387- |

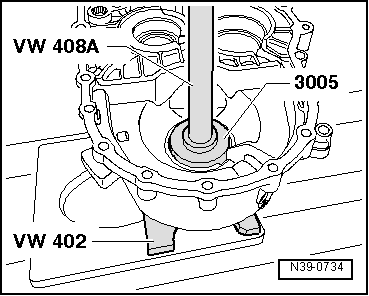

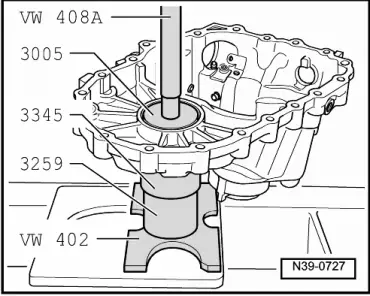

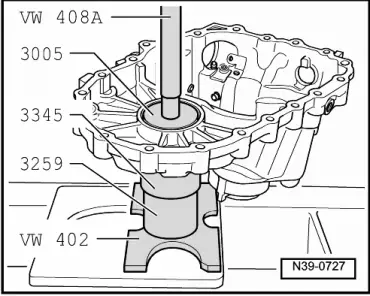

| t | Pressure plate -VW 402- |

| t | Press tool -VW 408 A- |

| t | Thrust plate -3005- |

| t | Tube - 3259- |

| t | Wheel bearing tube -3345- |

| t | Torque wrench -V.A.G 1331- |

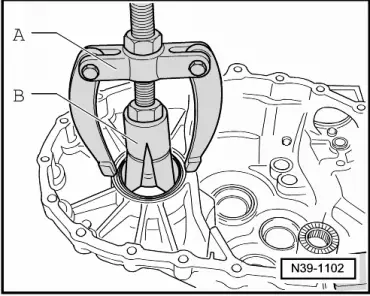

| t | Internal puller 46 … 58 mm -1 - Kukko 21/7- |

| t | Counter support -4 - Kukko 22/2- |

|

Note

Note

|

|

|

|

|

|

| Measured value | 0.70 mm |

| + Preload (constant) | 0.30 mm |

| Thickness of shim = | 1.00 mm |

|

|

|

| Shim thickness (mm) | |||

| 0.65 | 0.85 | 1.05 | 1.25 |

| 0.70 | 0.90 | 1.10 | |

| 0.75 | 0.95 | 1.15 | |

| 0.80 | 1.00 | 1.20 | |

|

|

|