| Checking hydraulic bucket tappets |

| Special tools and workshop equipment required |

Note | t

| Renew defective bucket tappets complete (cannot be adjusted or repaired). |

| t

| Irregular valve noises when starting engine are normal. |

| –

| Start engine and run until engine oil temperature reaches approx. 80 °C. |

| –

| Increase engine speed to about 2500 rpm for approx. 2 minutes. |

| If the hydraulic tappets are still noisy, locate defective tappet as follows: |

| –

| Remove upper part of intake manifold. |

| Continuation for all engine codes |

| –

| Remove cylinder head cover. |

| –

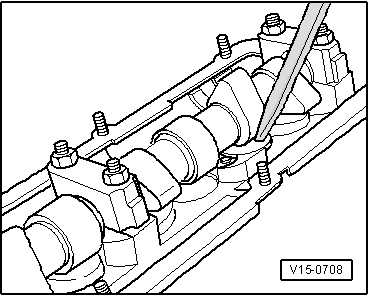

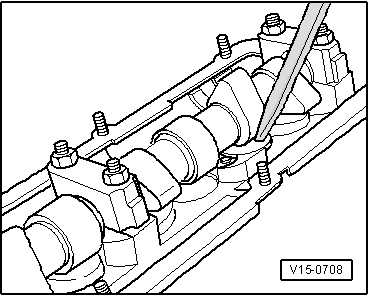

| Rotate crankshaft clockwise until cam of tappet to be checked is pointing upwards. |

| –

| Determine play between cam and bucket tappet. |

| –

| If play exceeds 0.1 mm, renew bucket tappet. If play is less than 0.1 mm or there is no play, continue with check as follows: |

|

|

|

Note

Note

Note

Note