| –

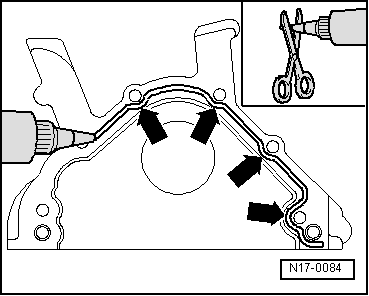

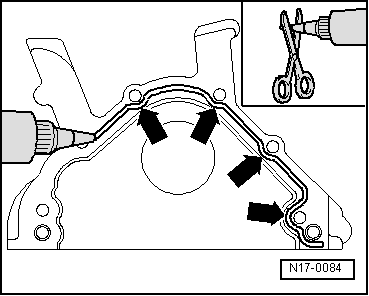

| Cut off tube nozzle at forward marking (approx. 3 mm nozzle Ø). |

| –

| Apply silicone sealing compound, as shown, to clean sealing flange sealing surface. Sealant bead must be: |

| t

| The sealant bead should be -arrows-: 2…3 mm thick |

Note | t

| Sealant bead should not be thicker, otherwise excess sealant can enter sump and block strainer in oil pump suction pipe and also drip onto sealing surface of crankshaft oil seal. |

| t

| Before applying sealant bead, cover sealing surface of oil seal with a clean rag. |

| –

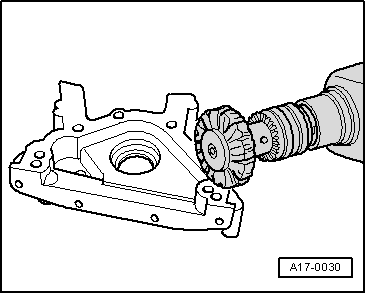

| Fit sealing flange immediately and lightly tighten all bolts. |

Note | To fit sealing flange with oil seal installed, use fitting sleeves -2080 A-. |

Note | To fit sealing flange with oil seal installed, use assembly tool -T10053-. |

| Continuation for all versions |

| –

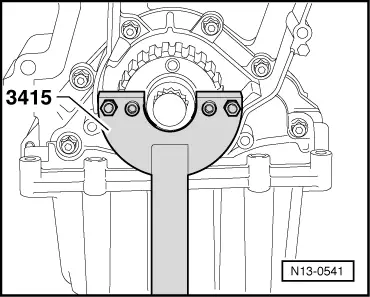

| Tighten sealing flange securing bolts diagonally and alternately. Torque setting: 15 Nm |

Note | Sealing compound must dry for approx. 30 minutes after installation. Only then fill with engine oil. |

| Installing toothed belt and adjusting valve timing → Chapter. |

|

|

|

Note

Note

Note

Note Note

Note Note

Note Note

Note