| –

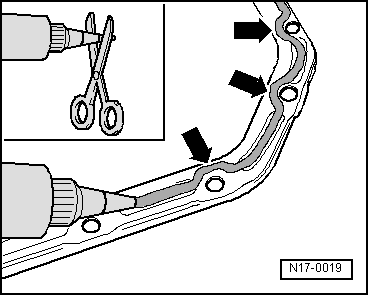

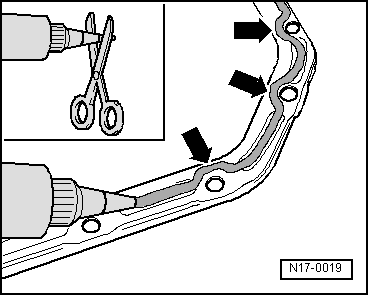

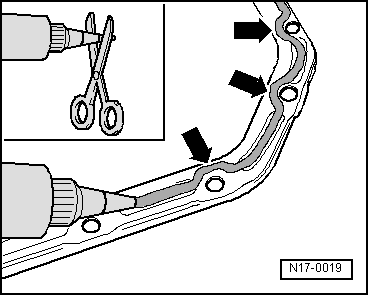

| Cut off tube nozzle at forward marking (Ø of nozzle approx. 3 mm). |

| –

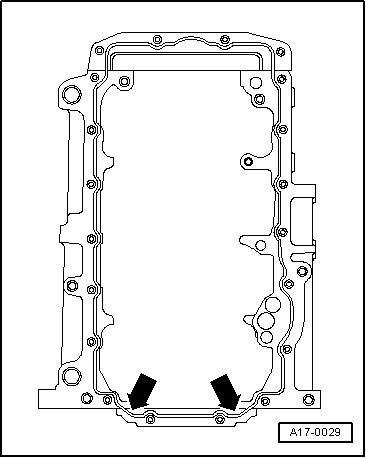

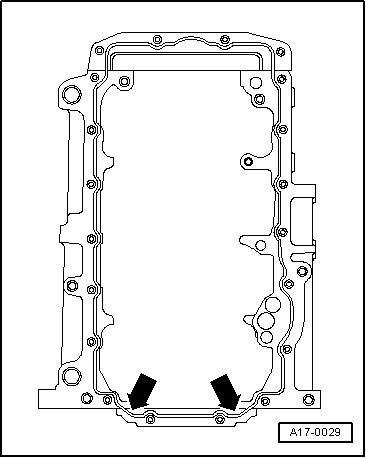

| Apply silicone sealant -D 176 404 A2-, as shown, to clean sump sealing surface. Sealant bead must be: |

| t

| Run bead along inner side of bolt holes -arrows-. |

Note | The sealant bead must not be thicker, otherwise excess sealing compound will enter the oil sump and may block the oil suction line strainer. |

|

|

|

Note

Note Note

Note

Note

Note

Note

Note Note

Note

Note

Note