|

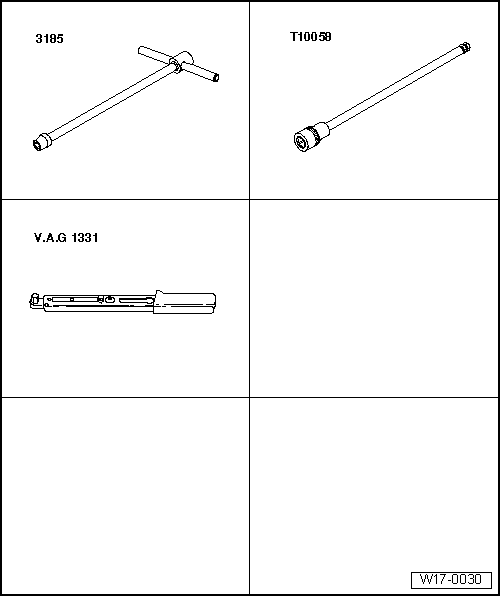

Special tools, workshop equipment, testers, measuring instruments and auxiliary items required

-

◆ 3185 Jointed wrench

-

◆ T10058 Socket insert

-

◆ V.A.G 1331 Torque wrench (5 ... 50 Nm)

-

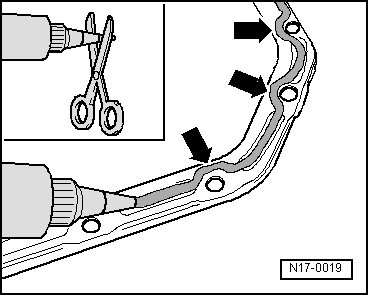

◆ Hand drill with plastic brush attachment

-

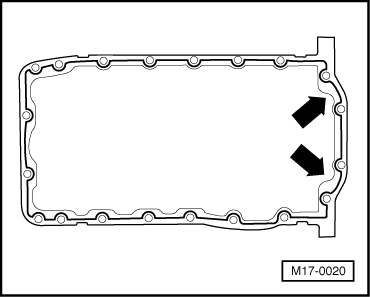

◆ Silicone sealing compound D176404 A2

Removing

-

‒ Remove centre and right-hand sound insulation:

=> General body repairs, exterior; Repair group 50; Noise insulation (petrol engine) - Assembly overview

-

‒ Remove oil sump protection

, fig. 2.

-

‒ Drain engine oil.

Note:

Observe waste disposal regulations!

Note:

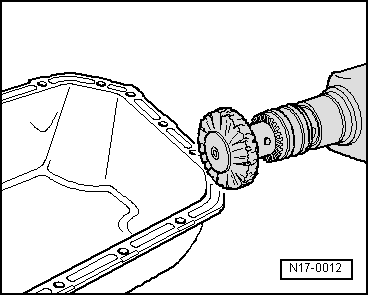

Loosen bolts on flywheel end of sump with jointed wrench 3185 and remove with socket T10058.

-

‒ Remove oil sump. Remove oil sump, it may be necessary to release sump by using light blows with a rubber headed hammer.

-

‒ Remove sealant residue from cylinder block with a flat scraper.

|