Golf Mk4

|

Servicing ignition system

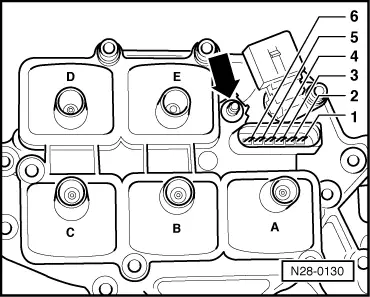

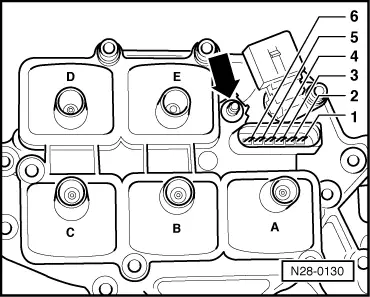

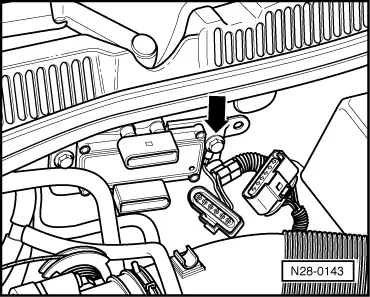

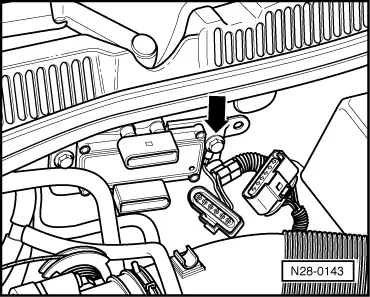

Checking ignition coils with output stage

|

|

|

|

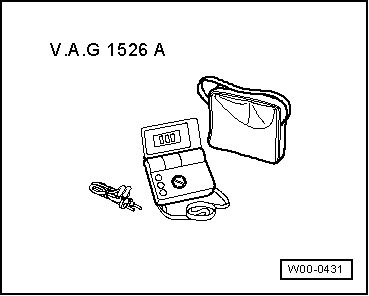

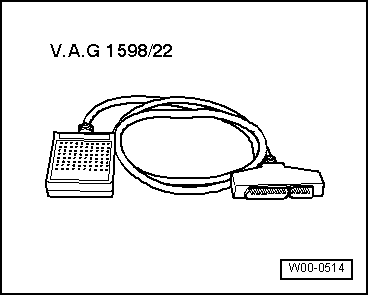

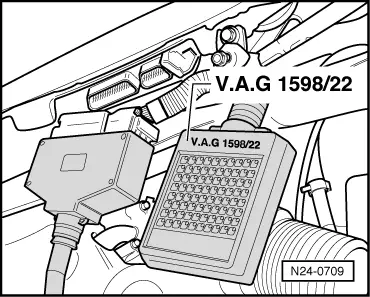

Perform check only when performance is poor or engine is shaking because its misfiring. Special tools, testers, measuring instruments and auxiliary items required

|

|

|

Check conditions |

|

|

|

|

|

|

Test sequence

Checking voltage supply |

|

|

If no voltage was present:

If the voltage was at least 11.5 V: Checking primary resistance |

|

|

If the specifications are not obtained:

If the specifications are obtained: |

|

|

|

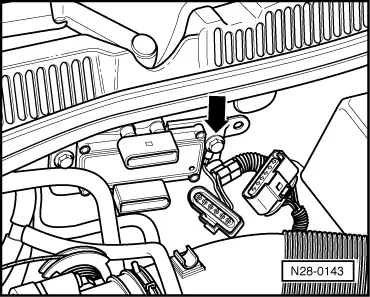

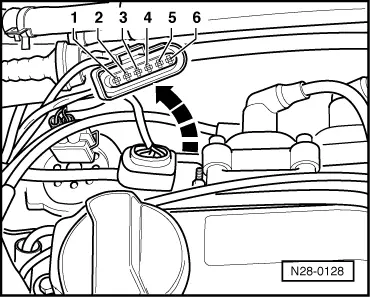

Checking activation

|

|

|

If no wiring fault is detected:

|

|

|

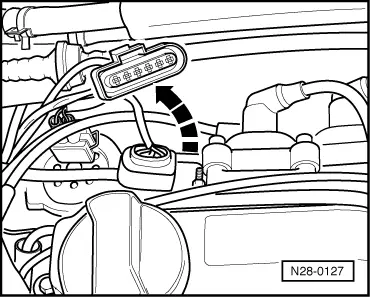

The LED must light up.

If the LED does not light up:

If not open circuit can be found:

The LED must light up.

|

|

|

|

If the activation of the output stage is fault-free:

If the activation of the output stage is interrupted at one or more connector contacts:

|

|

|

If no wiring fault is detected:

|