Golf Mk4

|

Checking components

Checking injectors

|

|

|

|

Check conditions

Test sequence

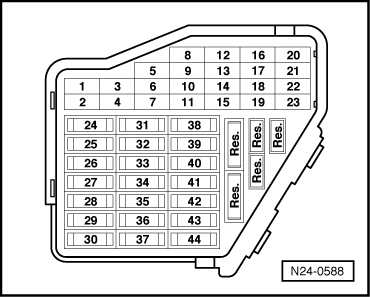

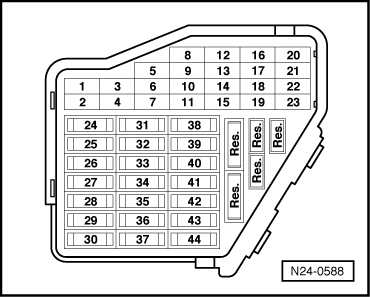

If one or more injectors do not click: Checking voltage supply Note: The positive supply for the injectors is a direct feed from the fuel pump relay (J17) via fuse 32 to the injectors.

=> Current flow diagrams, Electrical fault finding and Fitting locations binder

|

|

|

|

If no voltage was present:

=> Current flow diagrams, Electrical fault finding and Fitting locations binder

If the specifications are not obtained: Checking activation

=> General body repairs; Repair group 50; Body front; lock carrier service position

Note: Seal the intake channels in the intake manifold lower part and/or in cylinder head with clean cloths.

|

|

|

|

|

|

|

If the specifications are not obtained:

=> Current flow diagrams, Electrical fault finding and Fitting locations binder |

|

|

|

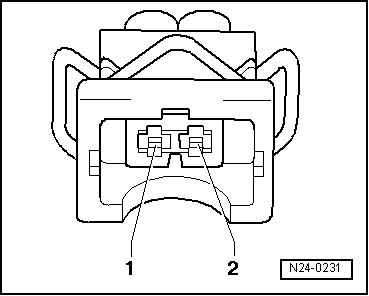

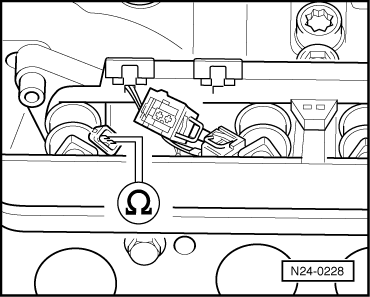

Checking resistance of injectors

When the engine is warm the resistance will be approx. 4...6 ωhigher. If the specification is not attained:

Note: Always renew seals. |

|

|

|

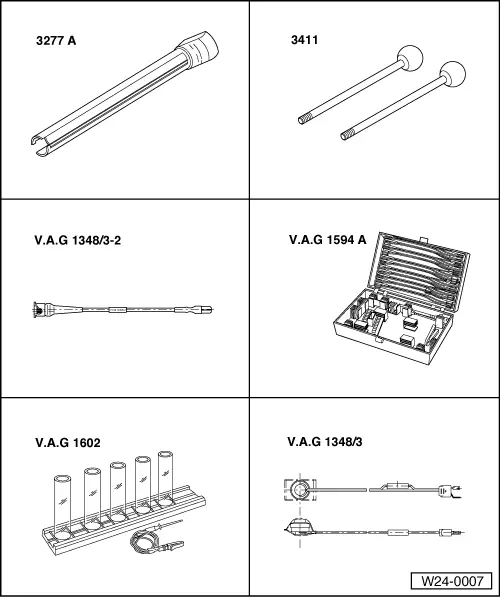

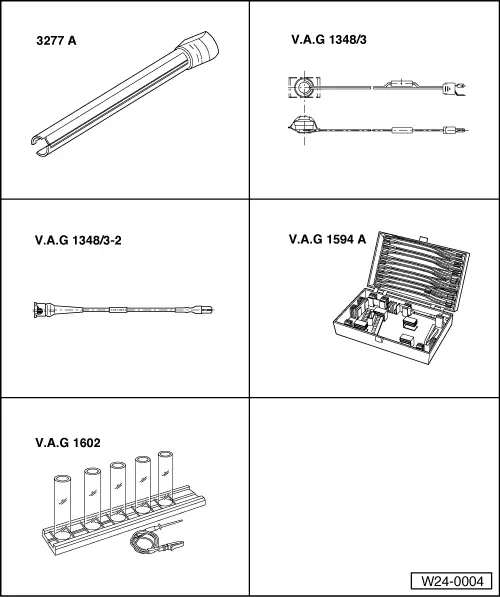

Check injectors for leaks and quantity injected Special tools, workshop equipment, test and measuring appliances and aux. items required

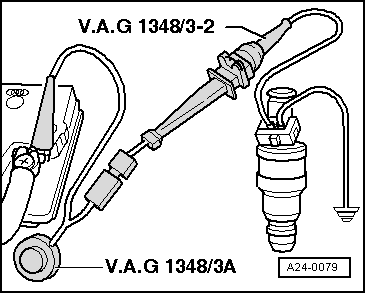

Checking for leaks Test sequence

=> General body repairs; Repair group 50; Body front; lock carrier service position

Note: Seal the intake channels in the intake manifold lower part and/or in cylinder head with clean cloths.

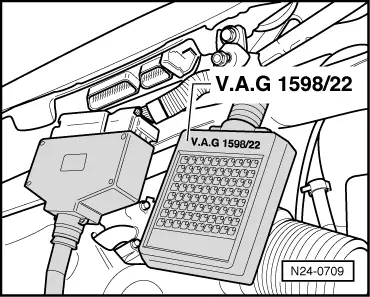

The fuel pump must audibly build up fuel pressure. Note: Initiating the final control diagnosis enables the fuel pump to run when the engine is stationary. The idling switch must remain closed otherwise the selected injector sprays 5 times. A maximum of 1 to 2 drops may leak per minute when fuel pump is running (visual check). If the fuel loss is greater:

|

|

|

Checking quantity injected

If the measured values of one or more injectors lie above or below the prescribed specifications:

Installing the injectors is performed logically in reverse order. But note the following:

|