Note | t

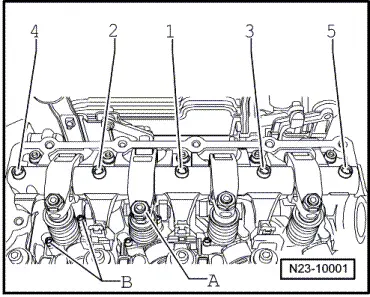

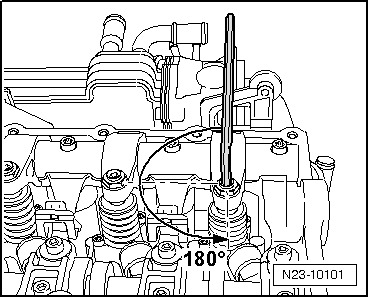

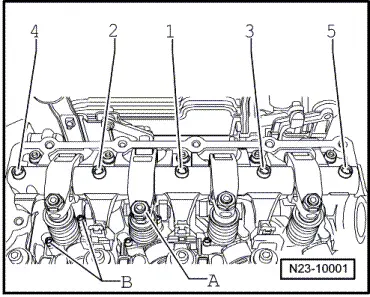

| When camshafts are installed, cams for No. 1 cylinder must point upwards. |

| t

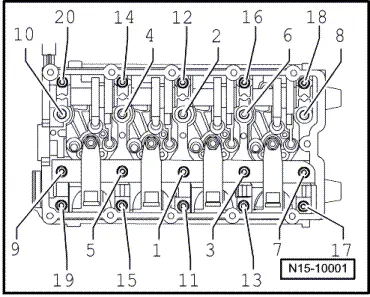

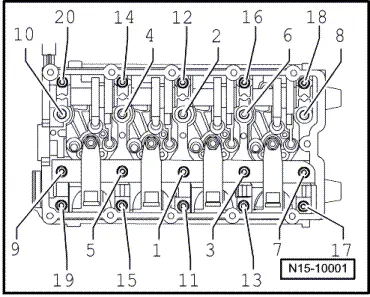

| Do not interchange used bearing shells (mark). |

| t

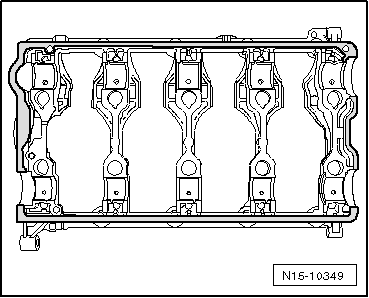

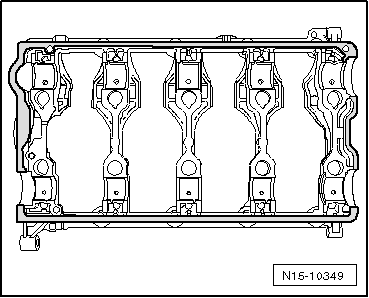

| When installing camshafts, ensure proper seating of retaining lugs in retaining frame and cylinder head. |

| t

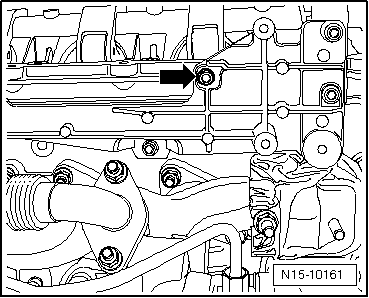

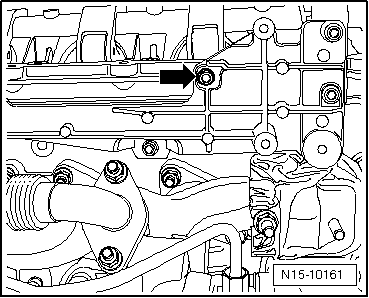

| Seal parting surface between retaining frame and cylinder head using silicone adhesive sealant -D 176501 A1- → Fig. |

| t

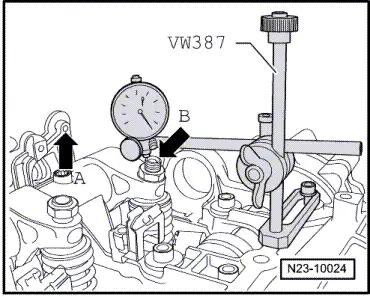

| Each time work is performed which requires adjustment of the unit injector, the adjustment screw in the rocker arm and also the unit injector ball stud must be renewed. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note