| Cleaning unit injectors (engine codes BMN, BKP, BMA, BUZ and BMR) |

| Special tools and workshop equipment required |

| t

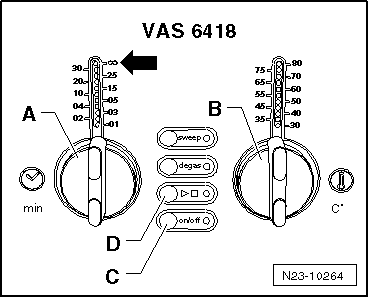

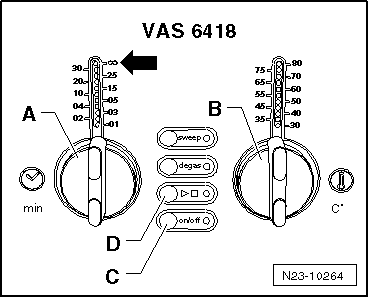

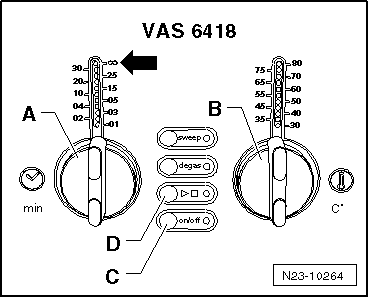

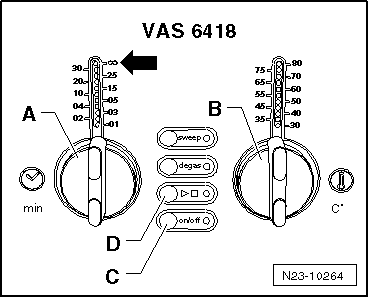

| Ultrasonic cleaner -VAS 6418- |

| t

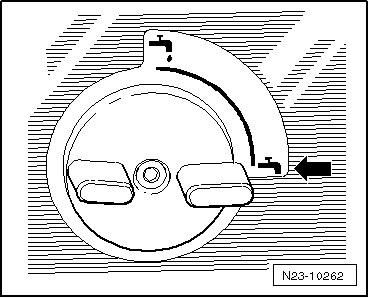

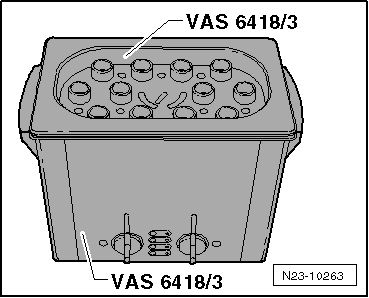

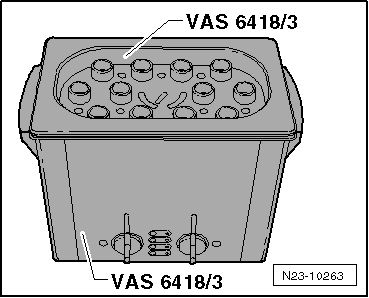

| Mounting plate for unit injectors -VAS 6418/3- |

| t

| Cleaner Tickopur -D 600 300 A2- |

Note | t

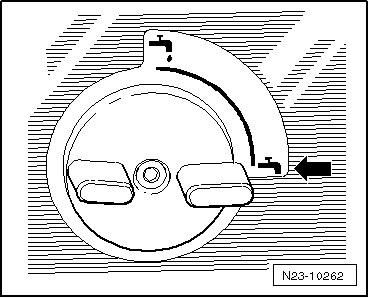

| Cleaning the unit injectors may only be carried out using the support plate for unit injectors -VAS 6418/3-. Under no circumstances should the unit injector be immersed in cleaning fluid. |

| t

| The unit injectors must be operated within 2 hours after they have been cleaned. |

| t

| To reduce the warm-up period of the cleaning fluid, it is recommended that warm tap water is filled into the system and the cover of the unit is fitted. |

| t

| Change cleaning fluid weekly and only clean max. five sets of unit injectors per bath. |

| t

| Replenish evaporated cleaning fluid with tap water. |

| t

| Do not clean any other components in the cleaning fluid. |

| t

| Do not clean the outside of the unit injectors mechanically (wire brush, abrasives, etc.). |

| t

| Renew O-rings, ball studs, adjusting and securing bolts. |

|

|

|

Note

Note

Note

Note