Note | t

| Before carrying out further work, disconnect battery earth strap. First check whether a coded radio is fitted. Obtain radio code first if necessary. |

| t

| The engine is removed downwards together with the gearbox. |

| t

| All cable ties which are opened or cut through when engine is removed must be replaced in the same position when engine is installed. |

Caution | When doing any repair work, especially in the engine compartment, pay attention to the following due to the cramped conditions: |

| t

| Route all types of lines (e.g. for fuel, hydraulics, active charcoal filter system, coolant, refrigerant, brake fluid and vacuum) and electrical wiring in their original positions. |

| t

| To avoid damage to lines, ensure sufficient clearance to all moving or hot components. |

|

| –

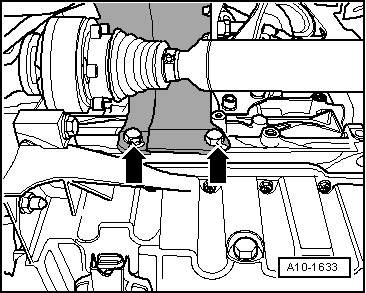

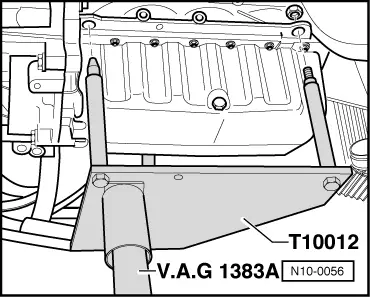

| Remove air filter housing with connecting hoses. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note