| –

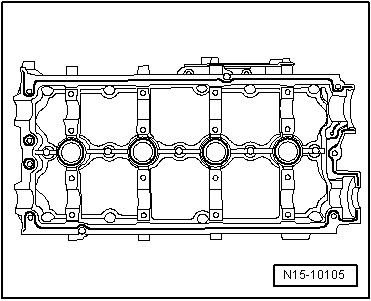

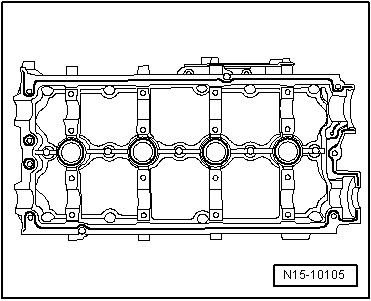

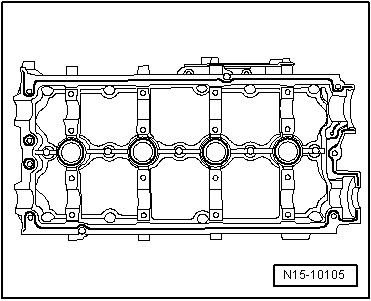

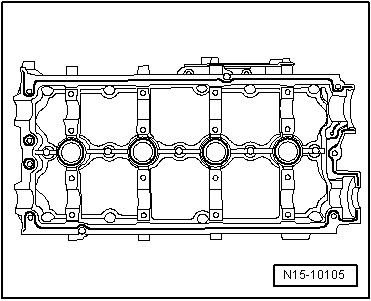

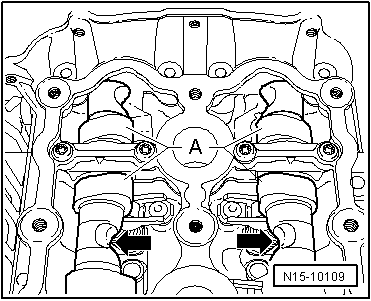

| Apply an even, slightly raised bead of sealant with sealant -D 154 103 A1- into clean retaining frame groove. |

Note | t

| Sealant must not be applied too thickly. If necessary wipe away excess sealant with a lint-free cloth. |

| t

| The retaining frame must be positioned and bolted on without interruption because the sealant begins to harden immediately when the sealing surfaces come into contact with each other. |

| t

| Observe expiry date of sealing compound. |

| –

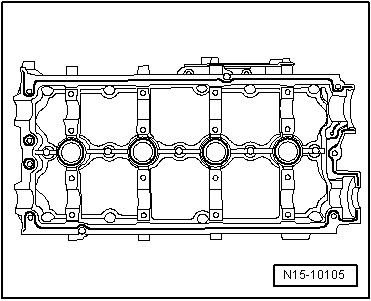

| Place retaining frame onto cylinder head. |

| –

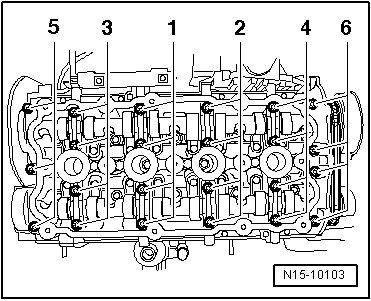

| Tighten new bolts gently, from inside outwards. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note

Note