Golf Mk6

| Removing and installing camshaft |

| Special tools and workshop equipment required |

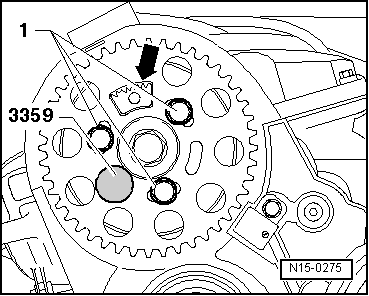

| t | Diesel injection pump locking pin -3359- |

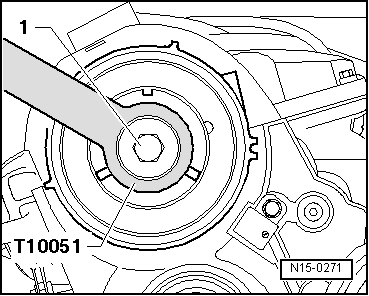

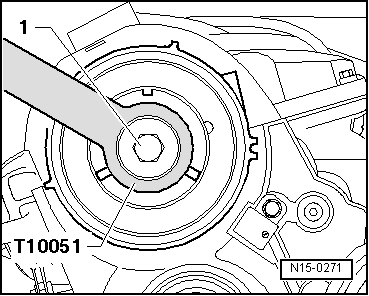

| t | Counterhold tool -T10051- |

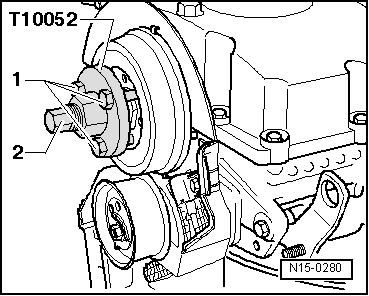

| t | Puller -T10052- |

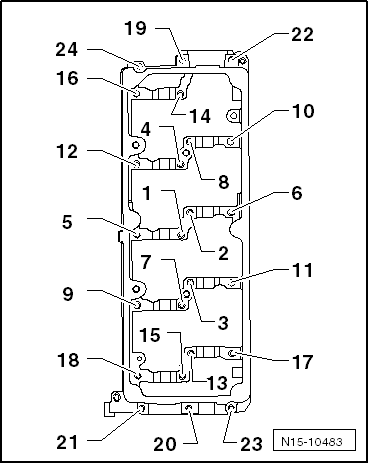

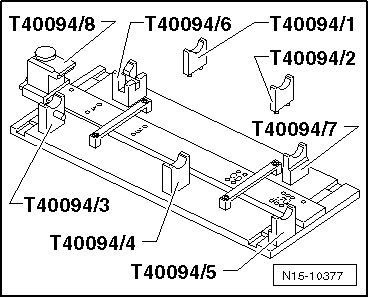

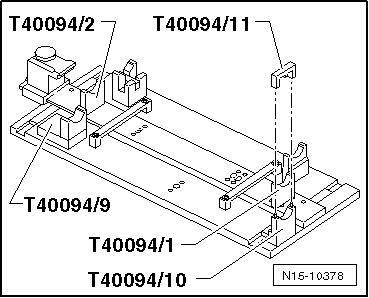

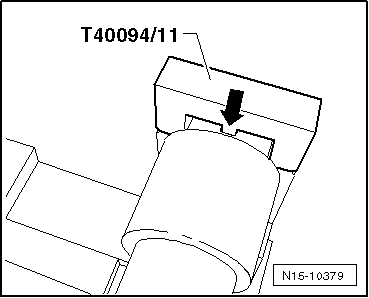

| t | Camshaft fitting tool -T40094- |

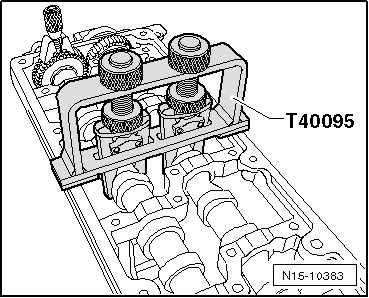

| t | Camshaft clamping tool -T40095- |

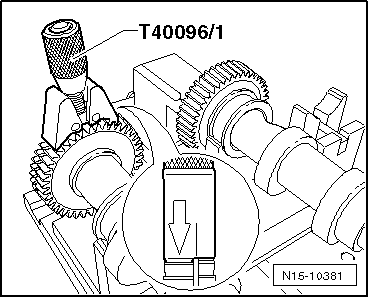

| t | Camshaft fitting tool -T40096- |

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Caution

Caution