| –

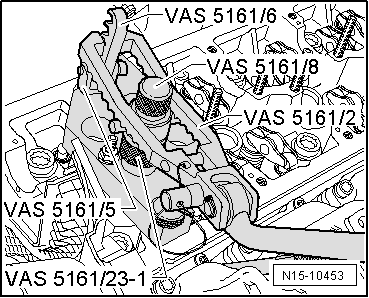

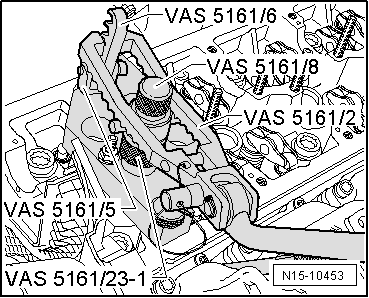

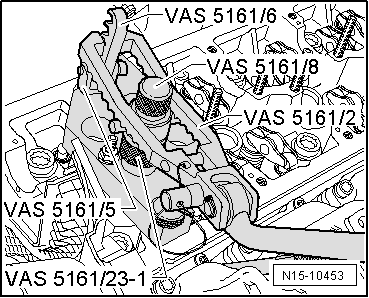

| Screw engaging fork -VAS 5161/5- with snap-in device -VAS 5161/6- into guide plate. |

| –

| Slide knurled spacer ring -VAS 5161/23-1- onto assembly cartridge -VAS 5161/8-. |

| –

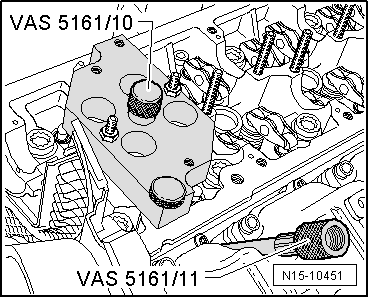

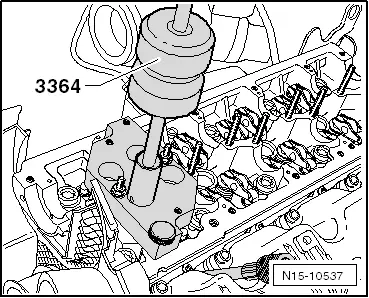

| Connect adapter -VAS 5161/11- to compressed air line using a commercially available connection piece, and apply constant air pressure. |

| l

| Minimum pressure: 6 bar |

| –

| Attach pressure fork -VAS 5161/2- to snap-in device and push assembly cartridge down. |

| –

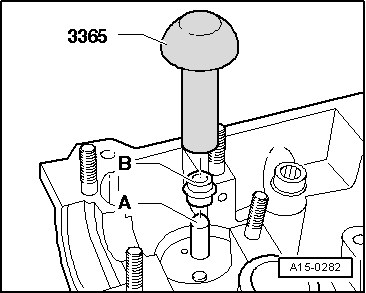

| At the same time, turn knurled screw of assembly cartridge clockwise until tips engage in valve cotters. |

| –

| Move knurled screw back and forth lightly to press apart valve cotters and capture them in the assembly piece. |

| –

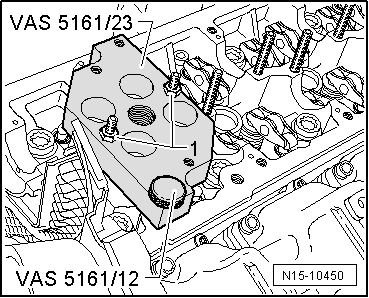

| Take out assembly cartridge with knurled spacer ring, valve plate and valve spring. |

|

|

|

Note

Note

Note

Note

Note

Note