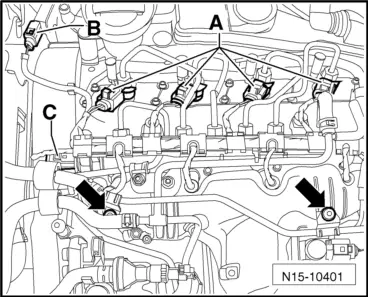

Removing and installing glow plugs for 20L CJAA engine

|

|

|

|

|

Note

Note

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

Note

Note

|

|

|

|

|

|

DANGER!

DANGER! Caution

Caution