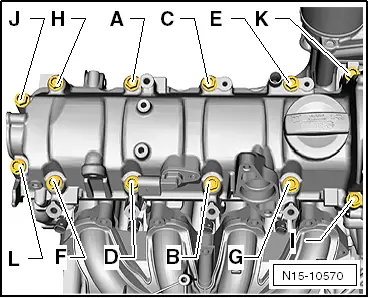

| Fitting the cylinder head cover |

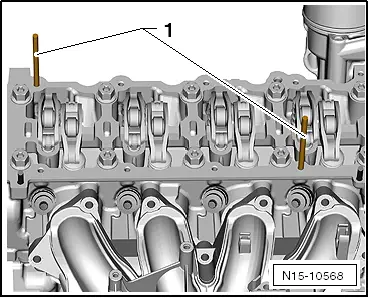

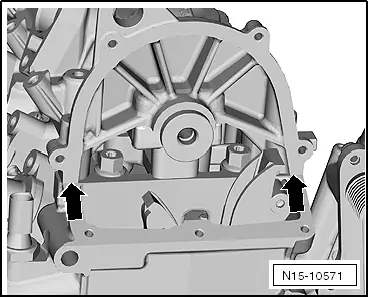

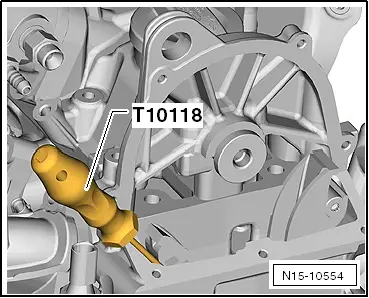

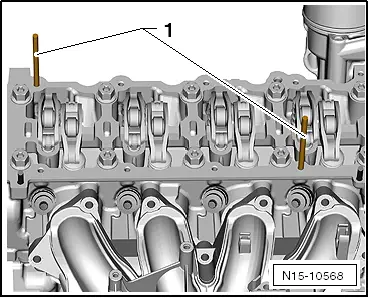

Caution | The studs (M6x70) must be screwed into cylinder head before cylinder head cover is installed. |

| The cylinder head cover is guided by the studs, so that the roller rocker fingers do not slip off the supporting elements. |

|

| –

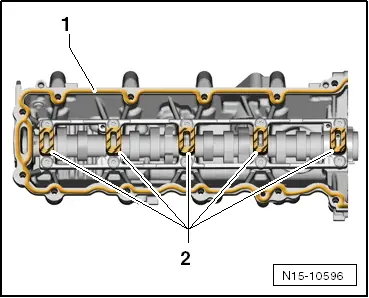

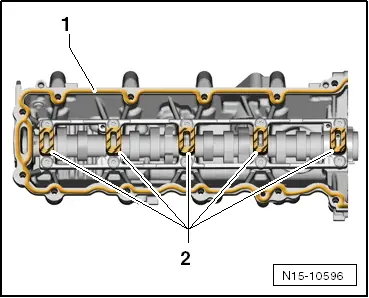

| Remove sealant residues from cylinder head and cylinder head cover with a rotating brush, e.g. a hand drill with a plastic brush (wear eye protection). |

| –

| Clean sealing surfaces carefully. They must be free of oil and grease. |

| –

| Also prevent dirt and residual sealant from entering cylinder head. |

| l

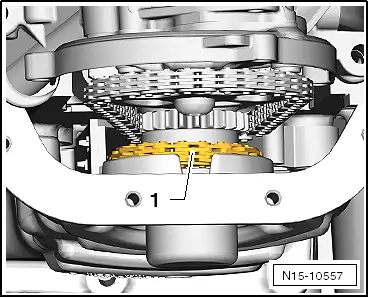

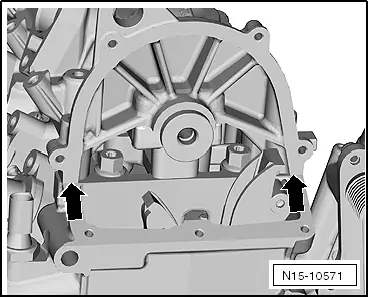

| The pistons must not be positioned at TDC. |

|

|

|

Note

Note

Note

Note

Note

Note

Note

Note