Golf Mk6

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Note

Note

|

|

| Specified torques |

| Component | Specified torque | ||||

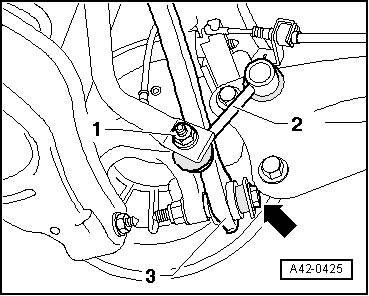

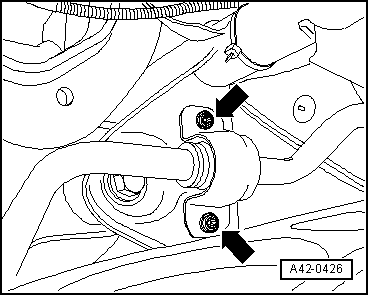

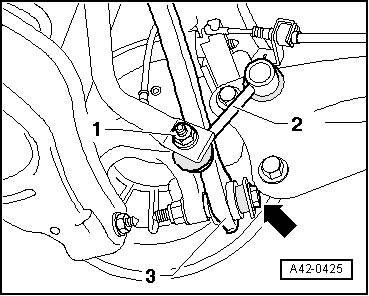

Track rod to wheel bearing housing

| 130 Nm + 90° further | ||||

Track rod to subframe

| 90 Nm + 90° further | ||||

Anti-roll bar to subframe

| 25 Nm + 45° further | ||||

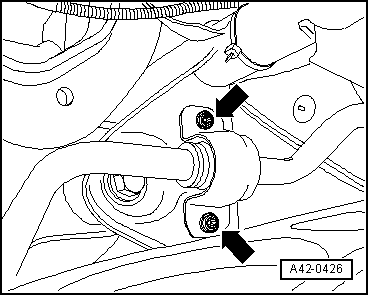

Anti-roll bar to coupling rod

| 45 Nm |

WARNING

WARNING