| –

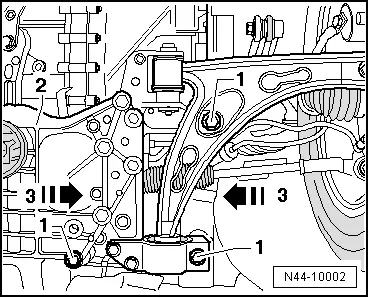

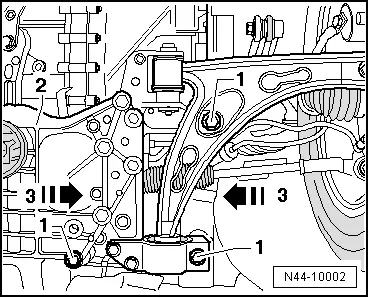

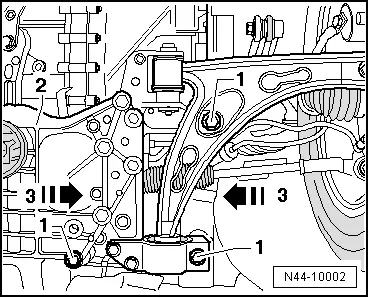

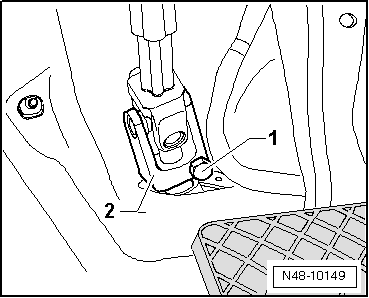

| Loosen bolts -1- for bracket attachment and subframe to body on both sides. |

| The camber adjustment range is limited by the tolerances within the bores in the brackets and the subframe. If the specified value is not reached by moving the components, these and the body must be inspected → Chapter. |

| –

| Specification for camber may be adjusted by moving subframe at brackets. |

| –

| Tighten bolts for subframe and brackets to body to specified torque plus extra turn angle. |

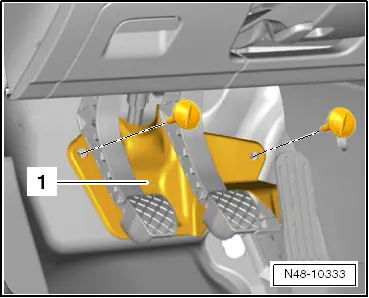

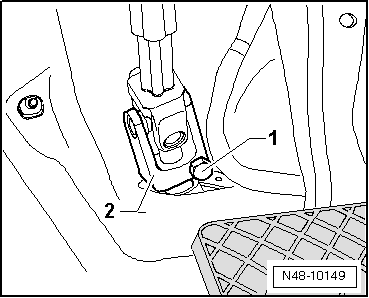

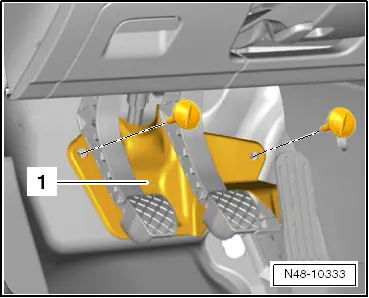

| Following the movement of the subframe and, consequently, the steering box, clearance between the steering column universal joint and the notch in the bulkhead must be checked. |

|

|

|

Note

Note

Note

Note