Passat (B3)

|

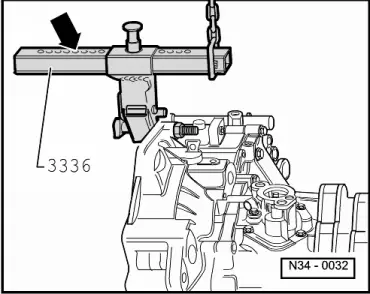

Removing and installing gearbox

Removing and installing gearbox - Vehicles with 4 cylinder engine -

Removing

Note: Note radio coding for vehicles with coded radio. On vehicles with G charger:

=> Repair group 21; Removing and installing parts of exhaust system |

|

|

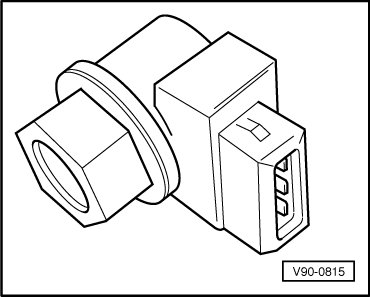

On vehicles with electronic speedometer:

|

|

|

|

|

|

|

|

|

Note: Do not depress clutch pedal. On vehicles with mechanical speedometer:

|

|

|

|

|

|

|

|

|

|

|

|

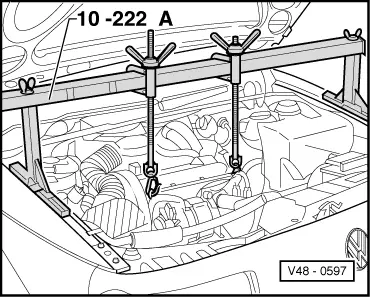

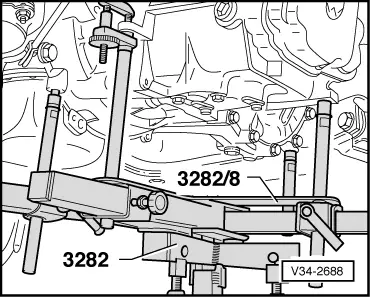

Attention!

The legs 10-222 A/1 are designed for the inclination of the bodywork. When the earlier type legs are used, there is a chance of accident!

|

|

|

=> Repair group 27; Removing and installing starter.

|

|

|

=> Repair group 26; Removing and installing parts of exhaust system.

|

|

|

|

|

|

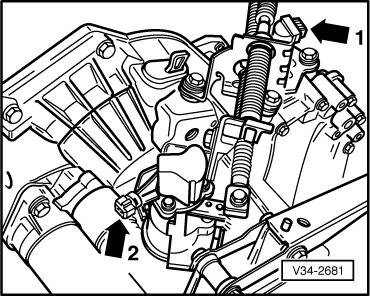

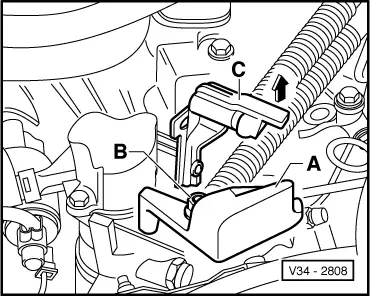

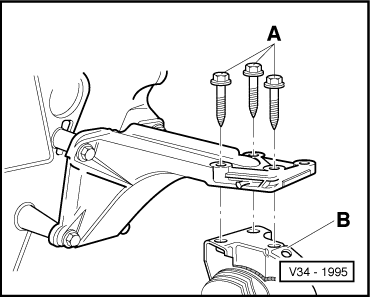

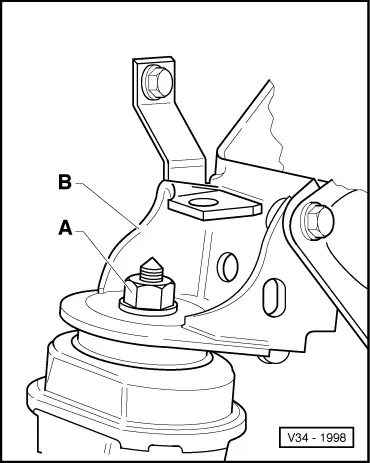

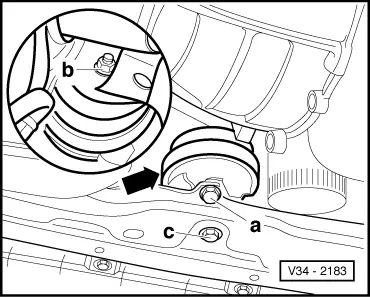

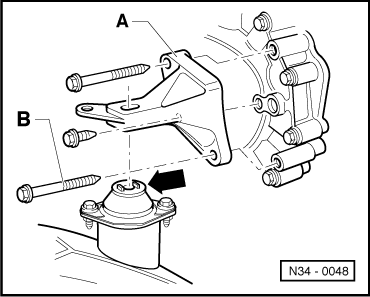

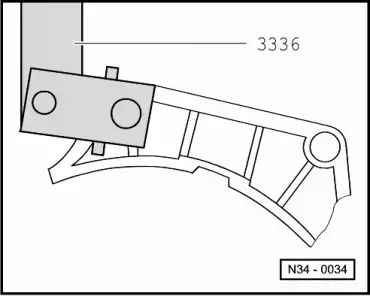

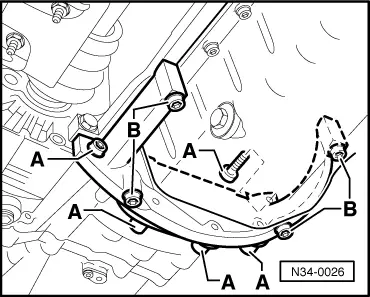

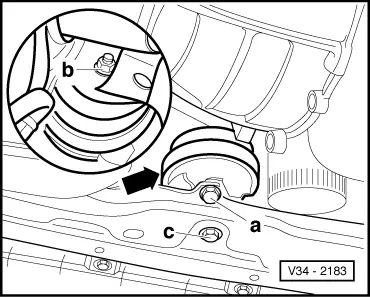

To do this remove gearbox console securing bolt -B- as follows:

Note: Do not damage P.A.S. pipe when moving engine/gearbox assembly. |

|

|

|

|

|

|

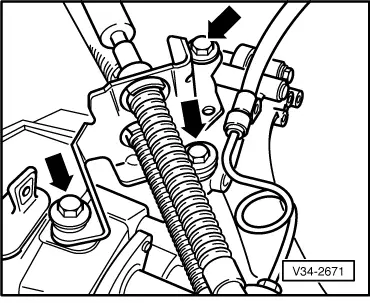

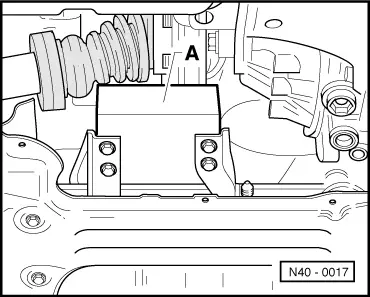

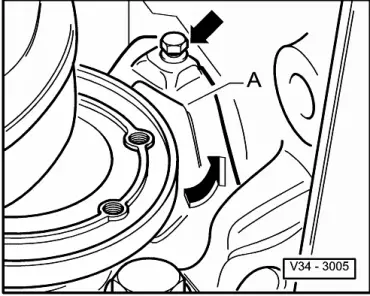

On vehicles with 4 valve engine:

|

|

|

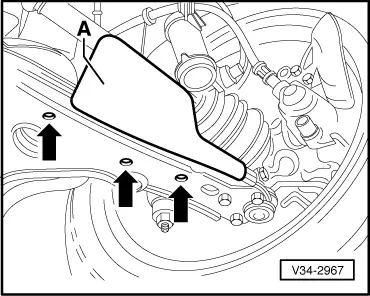

Note: Do not damage P.A.S pipe.

|

|

|

|

|

Note: Do not damage P.A.S pipe when lowering gearbox. |

|

|

|

|

|

|

Notes:

|

|

|

|

|

|

=> Running gear; Repair group 40; Servicing drive shaft

=> Repair group 27; Removing and installing starter.

Tightening torques |

|

|||||||||||||||||||||||||

|

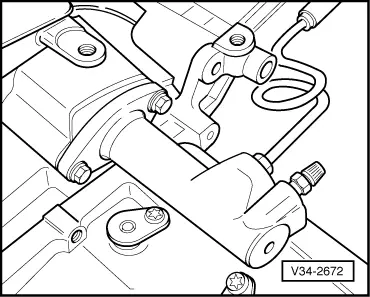

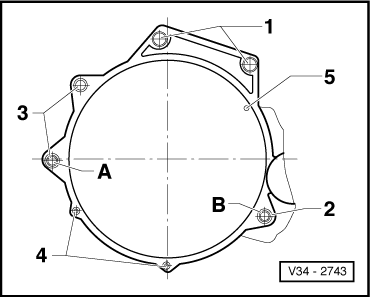

→ Gearbox to engine

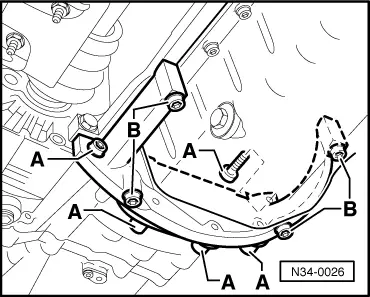

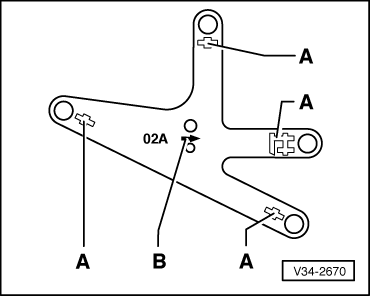

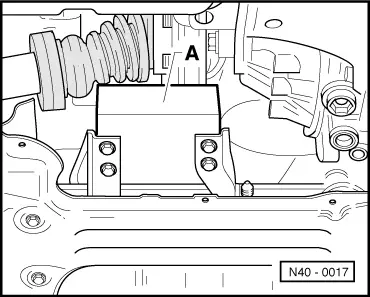

1) Also starter to gearbox 2) Flywheel large cover plate (not on vehicles with 4 valve engine) 3) Flywheel small cover plate Pos. A + B - Dowel sleeves |

|

|||||||||||||||||||||||

|

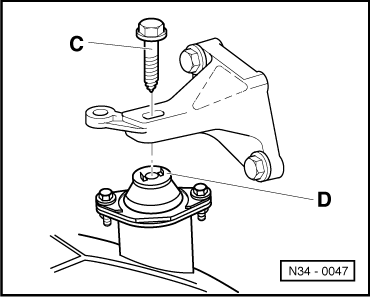

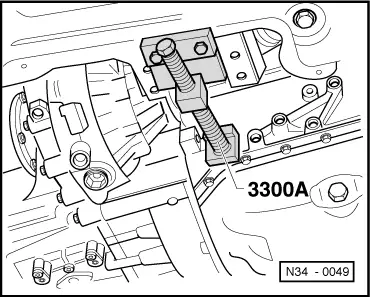

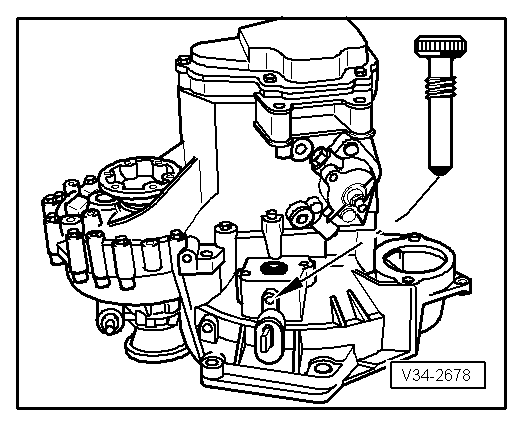

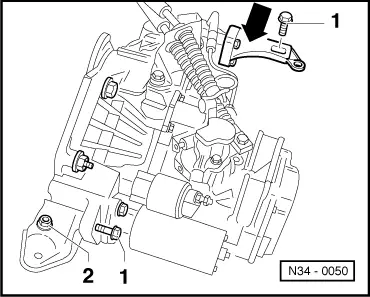

→ Assembly mountings

| |||||||||||||||||||||||

|

|||||||||

|

→ Front engine mounting to:

| |||||||||

|

||||||||||||||||||

| ||||||||||||||||||