Passat (B3)

|

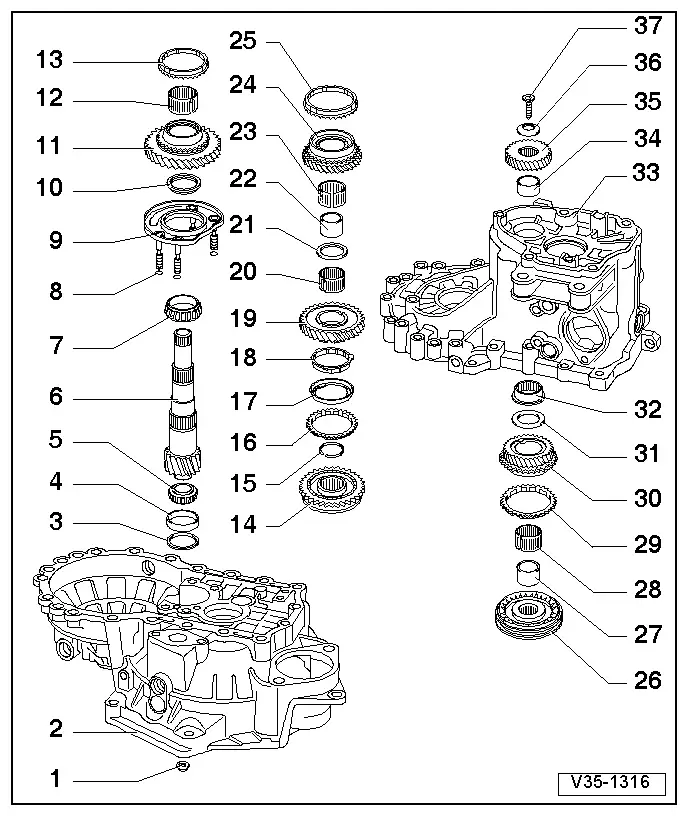

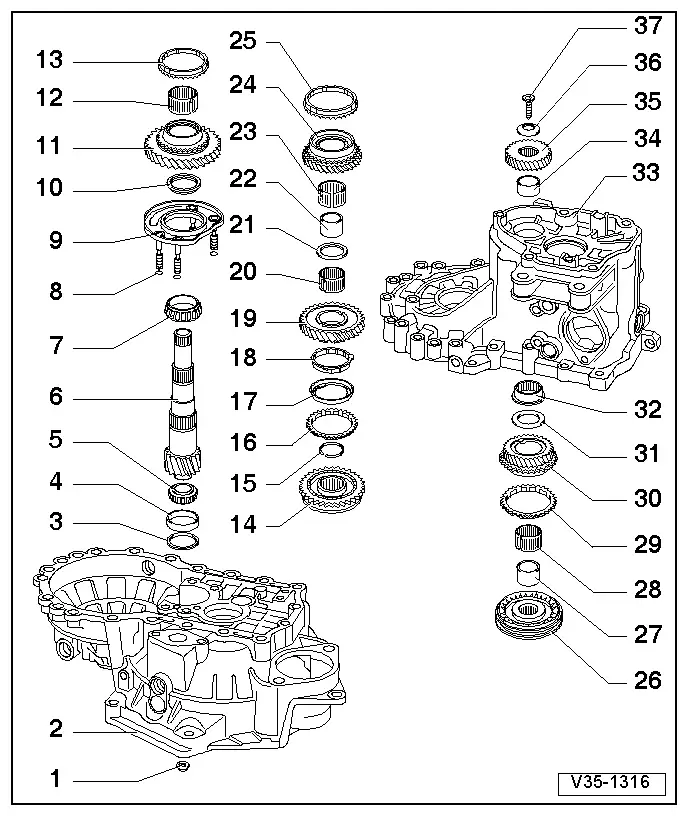

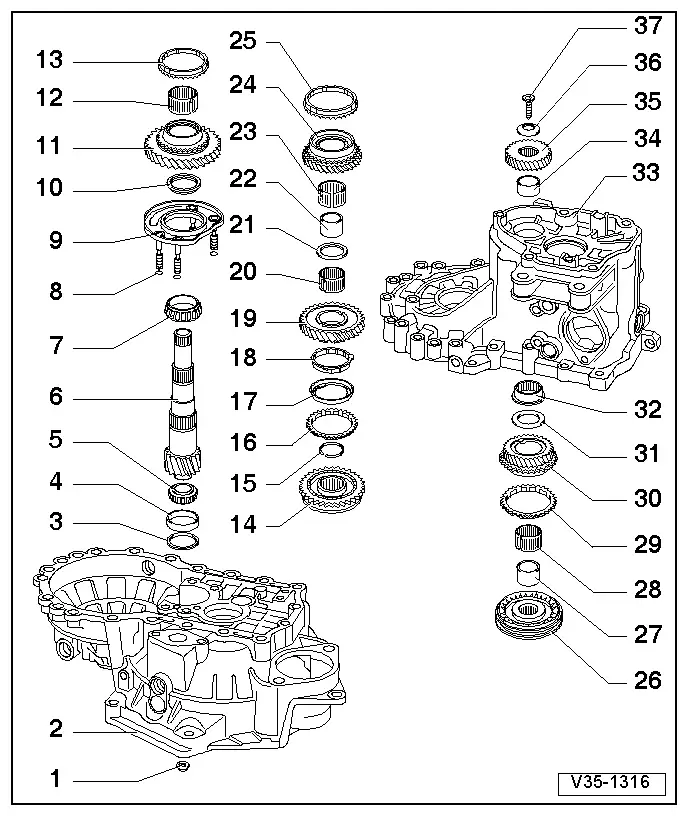

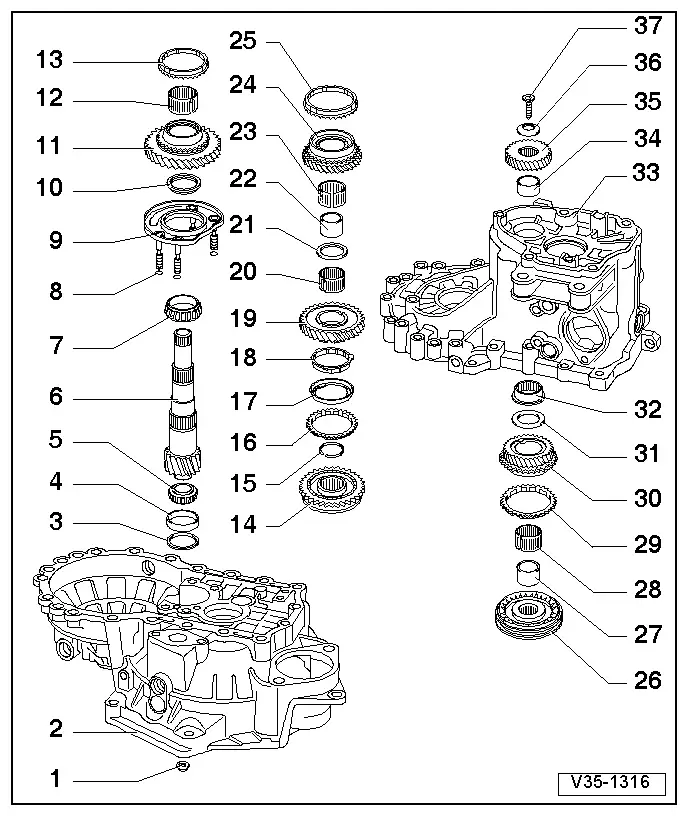

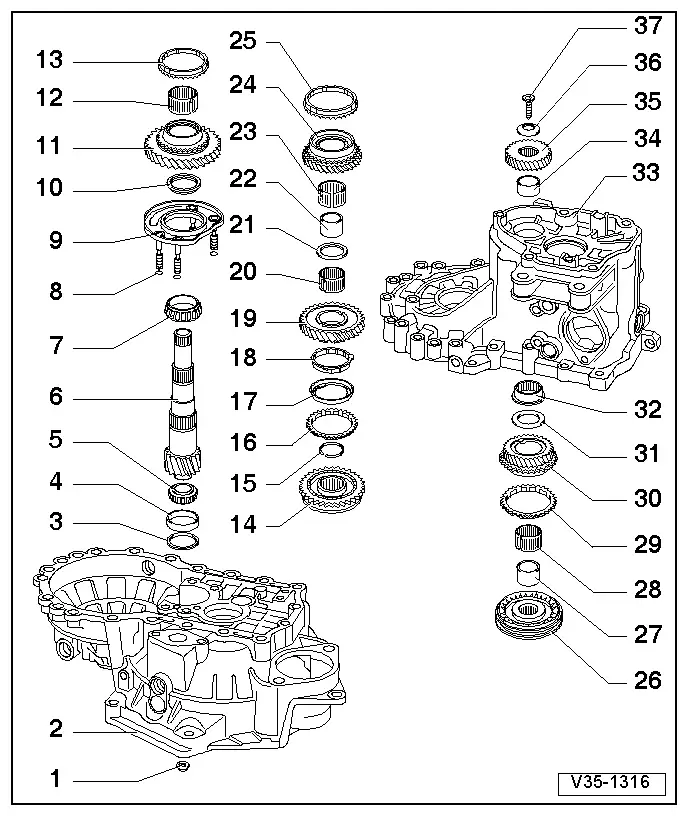

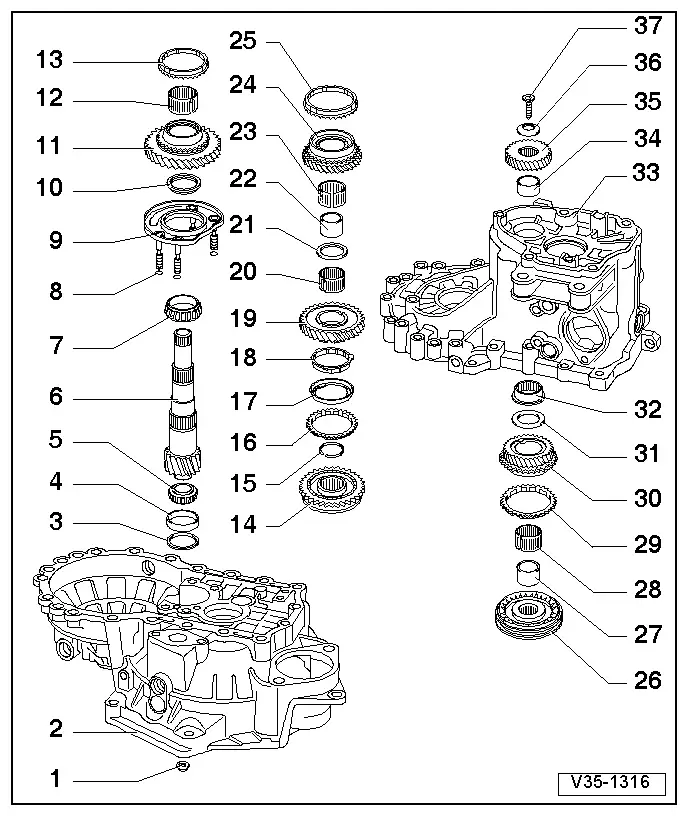

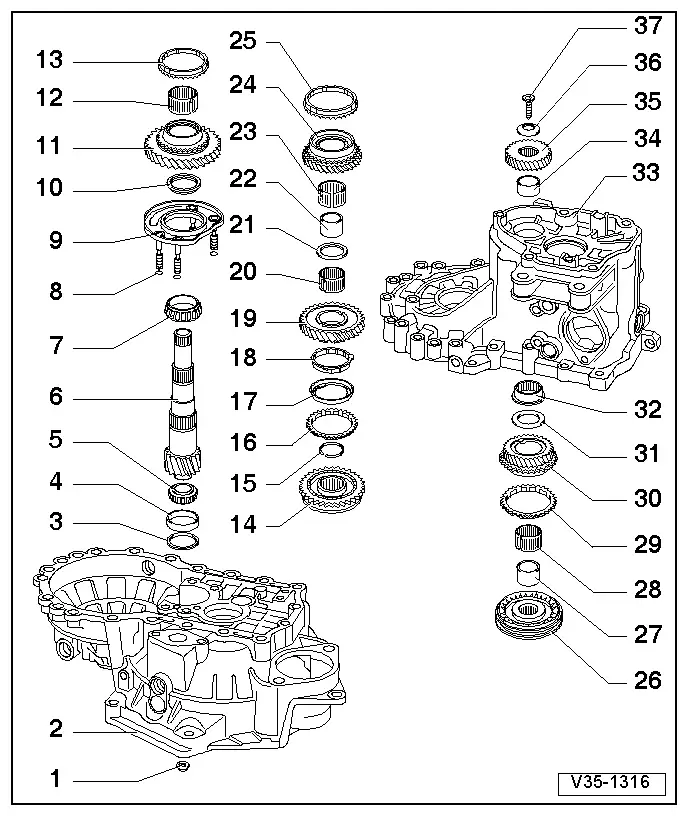

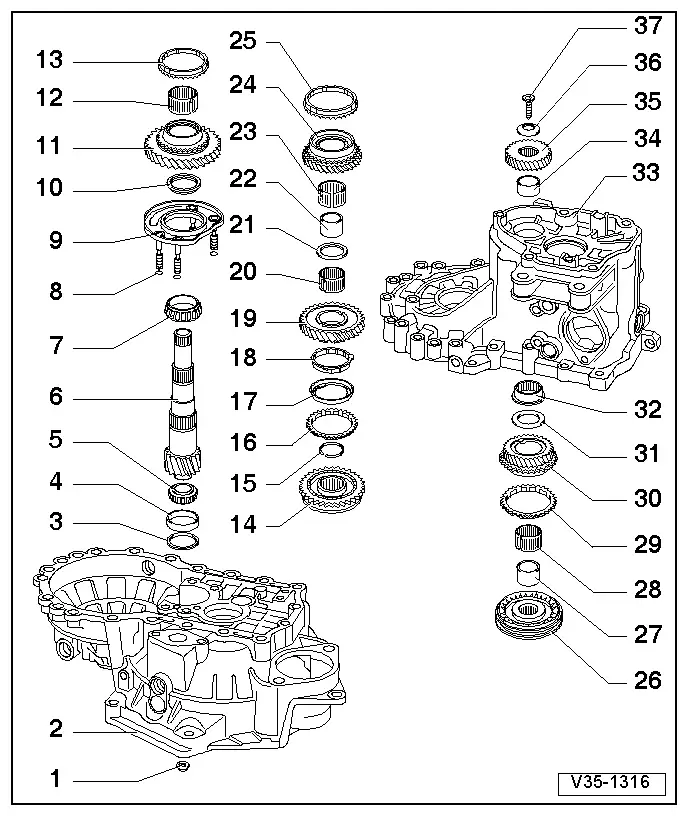

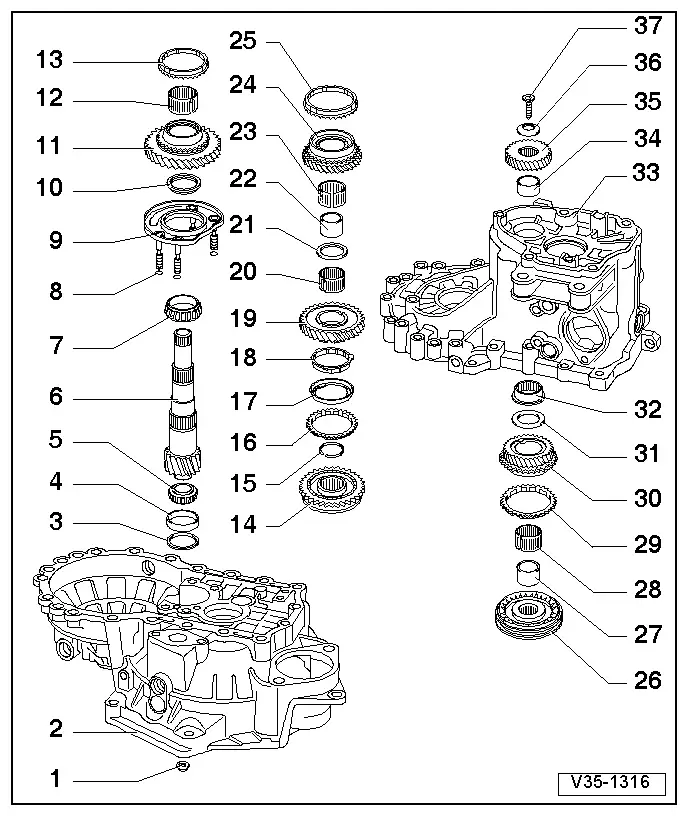

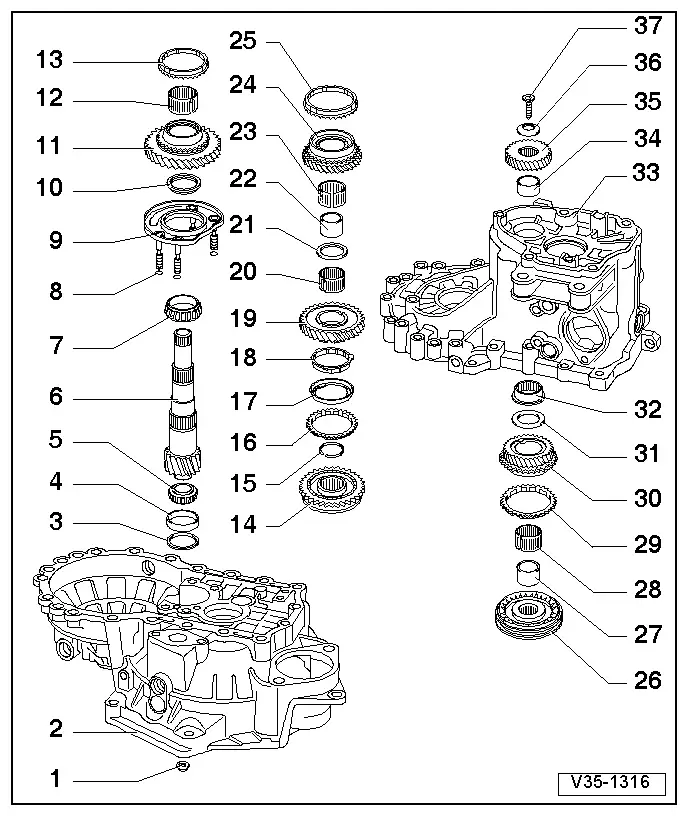

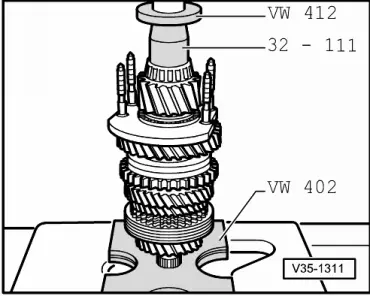

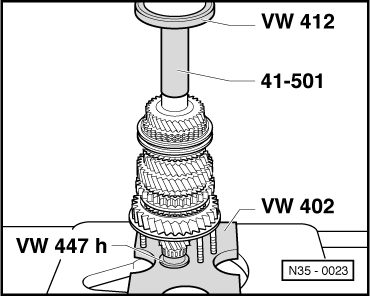

Dismantling and assembling output shaft (pinion shaft)

Dismantling and assembling output shaft (pinion shaft)

|

|

|

|

Notes:

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

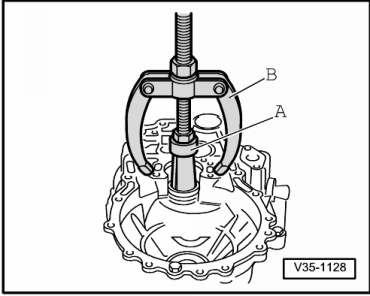

→ Fig.1 Pulling out small taper roller bearing outer race A - Internal extractor 37 ... 46 mm, e.g. Kukko 21/6 B - Counter support, e.g. Kukko 22/2 |

|

|

|

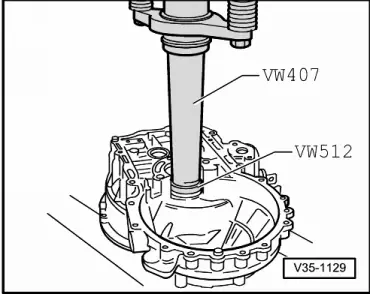

→ Fig.2 Pressing in small taper roller bearing outer race |

|

|

|

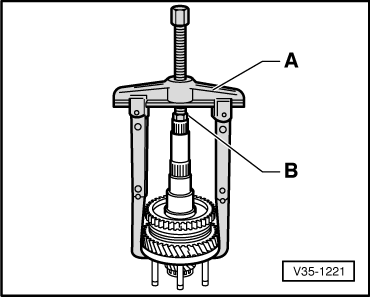

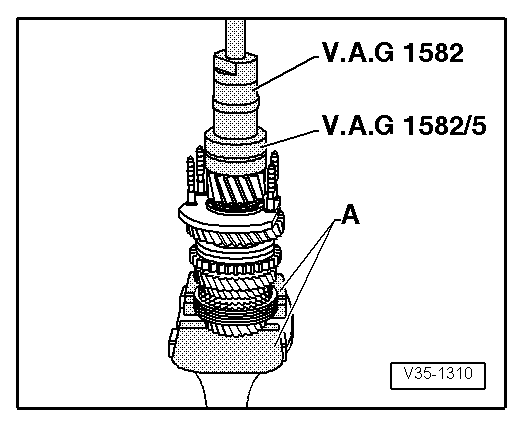

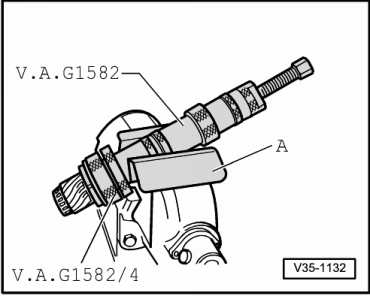

→ Fig.3 Pulling off small taper roller bearing inner race A - Vice clamps/vice

|

|

|

|

→ Fig.4 Pressing on small taper roller bearing inner race |

|

|

|

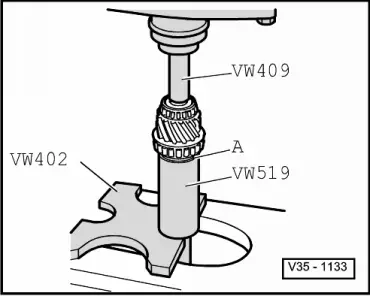

→ Fig.7 Pulling off large taper roller bearing inner race A - Vice clamps

|

|

|

|

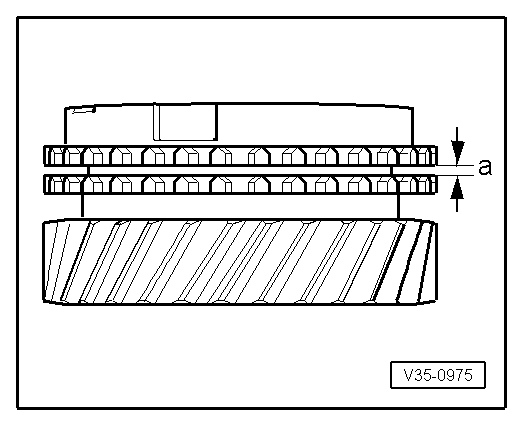

→ Fig.8 Pressing on large taper roller bearing inner race A - Thrust washer

|

|

|

|

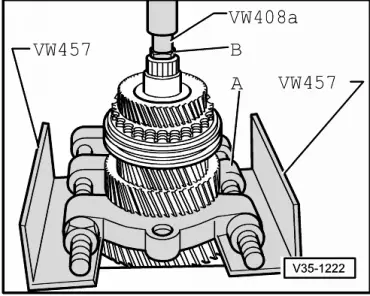

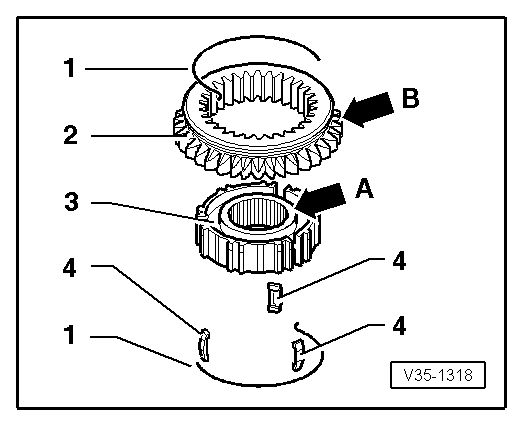

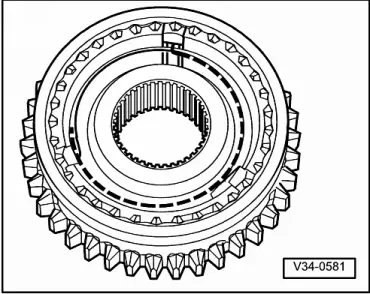

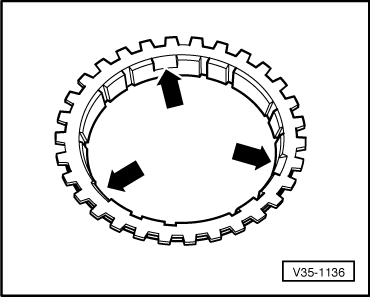

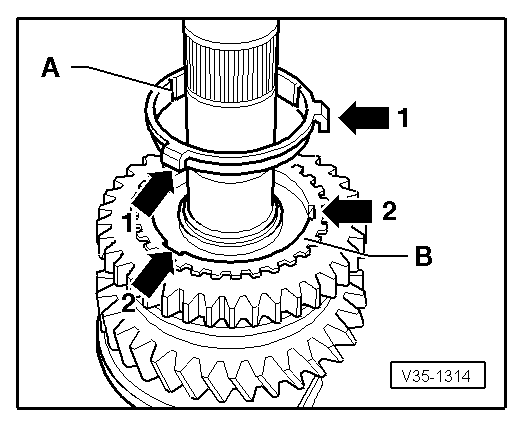

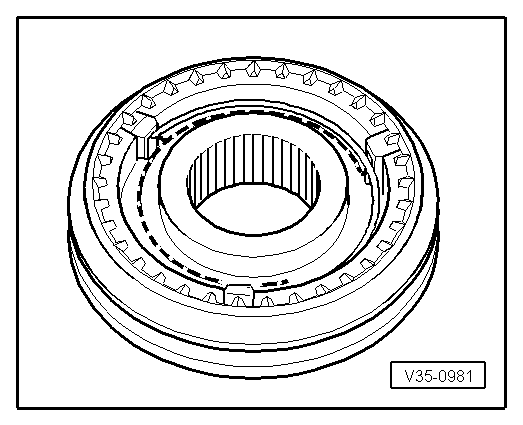

→ Fig.10 Dismantling and assembling 1st and 2nd gear locking collar and synchro-hub

The wide shoulder of the synchro-hub (arrow A) and the outer splines of the locking collar (arrow B) face opposite directions after assembly. Recesses for locking pieces on synchro-hub and locking collar must align. |

|

|

|

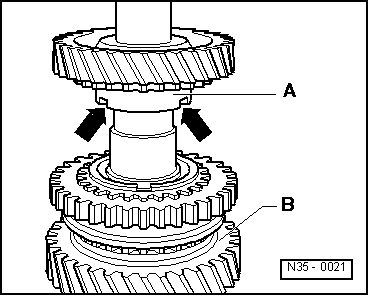

→ Fig.11 Assembling 1st and 2nd gear locking collar/synchro-hub

|

|

|

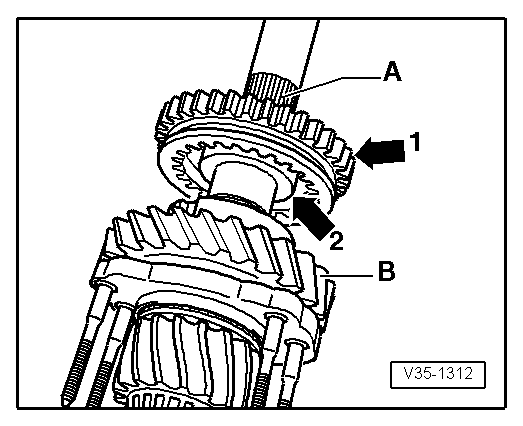

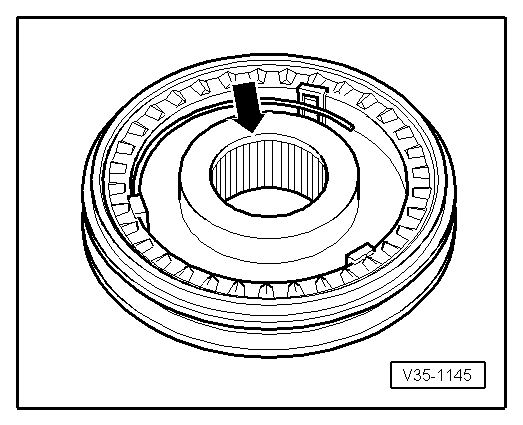

|

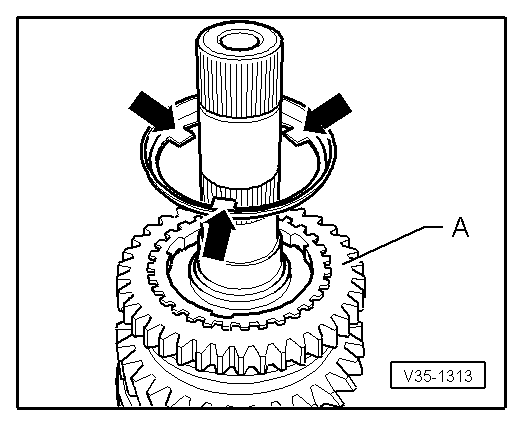

→ Fig.12 Installation position 1st and 2nd gear locking collar/synchro-hub The locking collar splines (arrow 1) point to splines for 3rd/4th gear synchro-hub -A-. The wide shoulder of the synchro-hub (arrow 2) then faces to 1st gear -B-. |

|

|

|

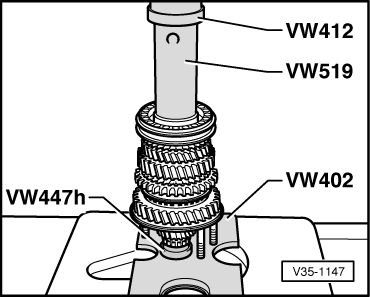

→ Fig.13 Pressing on 1st and 2nd gear locking collar/synchro-hub Note: Before pressing on, place 1st gear synchro-ring on 1st gear wheel. |

|

|

|

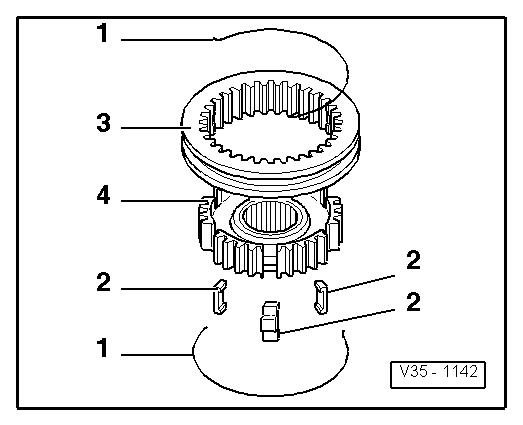

→ Fig.14 Identifying 1st and 2nd gear synchro-rings

Only the 2nd gear synchro-ring with 2 x ground down half teeth is available as a spare part. |

|

|

|

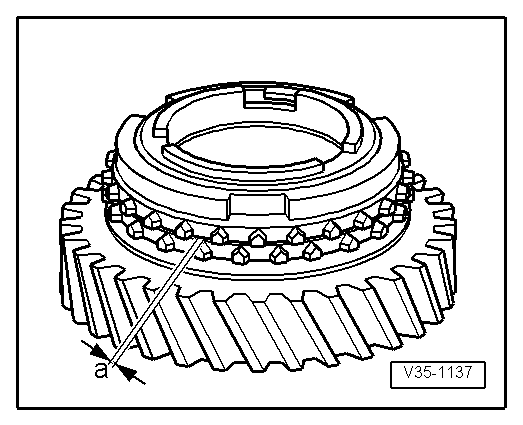

→ Fig.15 Distinguishing 1st and 2nd gear synchro-rings

|

|

|||||||

|

→ Fig.16 Checking 2nd gear synchro-ring for wear

|

|

|

|

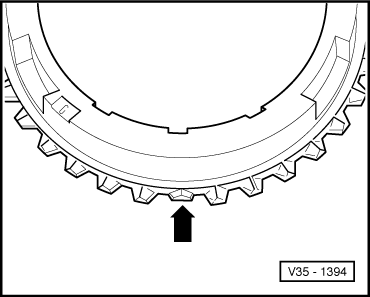

→ Fig.17 Installation position outer-ring The lugs (arrows) face to 1st gear -A- |

|

|||||||

|

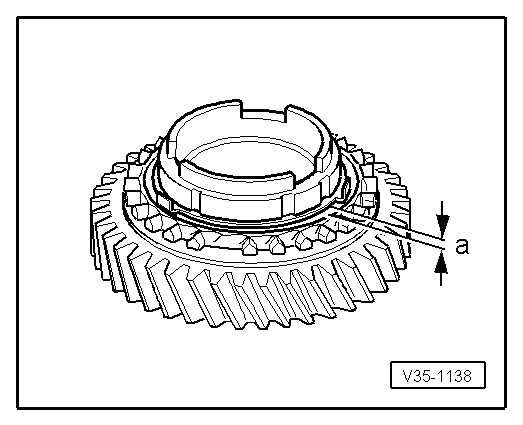

→ Fig.18 Checking inner-ring for wear

|

|

|

|

→ Fig.19 Installation position synchro-ring (inner-ring) -A- The lugs (arrow 1) locate in the recesses (arrow 2) in the synchro-ring -B-. |

|

|

|

→ Fig.20 Installation position 2nd gear wheel The higher shoulder -A- faces to 1st gear -B-. The recesses in the shoulder (arrows) locate with the lugs of the outer-ring (arrow => Fig.17 ) |

|

|

|

→ Fig.21 Pressing on needle roller bearing sleeve for 3rd gear |

|

|

|

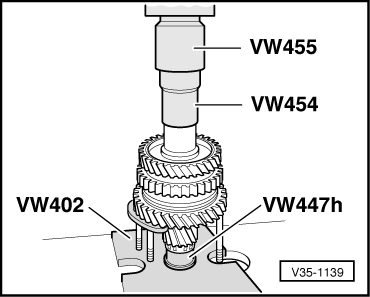

→ Fig.22 Dismantling and assembling 3rd and 4th gear locking collar and synchro-hub

The recesses for locking pieces in synchro-hub and locking collar must align. |

|

|

|

→ Fig.23 Assembling 3rd and 4th gear locking collar/synchro-hub The locking collar has been pushed over the synchro-hub.

|

|

|

|

→ Fig.24 Installation position 3rd and 4th gear locking collar/synchro-hub Chamfer (arrow) faces to 4th gear. |

|

|

|

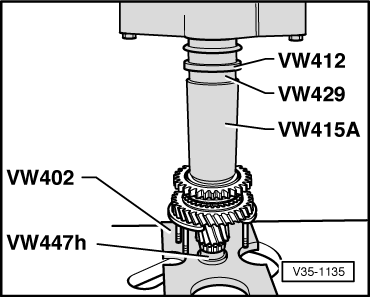

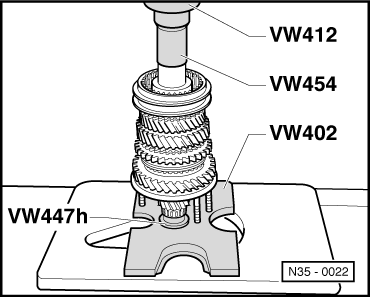

→ Fig.25 Pressing on 3rd and 4th gear synchro-hub with locking collar |

|

|

|

→ Fig.26 Pressing on sleeve for 4th gear needle roller bearing |

|

|

|

→ Fig.27 Pressing on sleeve for output shaft needle roller bearing |