Passat (B3)

|

Adjusting differential

Adjusting differential

The differential must be adjusted, when

or the

have been renewed. Adjustment overview .

Note: Inner and outer taper roller bearing races are a pair. Do not interchange.

|

|

|||||||||||||||||||

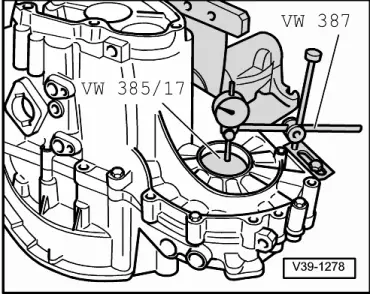

Note: Do not turn differential when measuring otherwise the bearing will settle and a false measurement will be given. Determining shim thickness The specified bearing preload is obtained by adding a constant figure (0.40 mm) to the reading obtained. Example:

The following shims are available:

If the size of shim required is larger than those listed in the table, insert two shims totalling the correct figure. Varying tolerances make it possible by measuring the shims to obtain the exact shim thickness required.

|

|

|

|

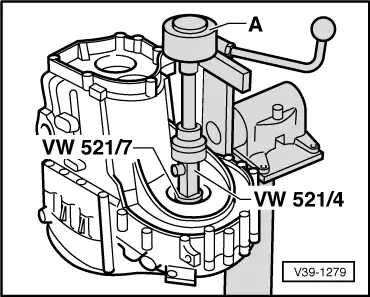

→ Checking friction moment A - Commercial torque gauge 0 ... 600 Ncm

Friction moment:

|