Passat (B3)

|

|

=> Repair group 26; Removing and installing parts of exhaust system.

|

|

|

=> Repair group 42; Servicing rear axle (vehicles with four wheel drive). Note: Do not loosen the brake pressure regulator lever clamp on anti-roll bar but after removing anti-roll bar detach spring at lever. |

|

|

|

|

|

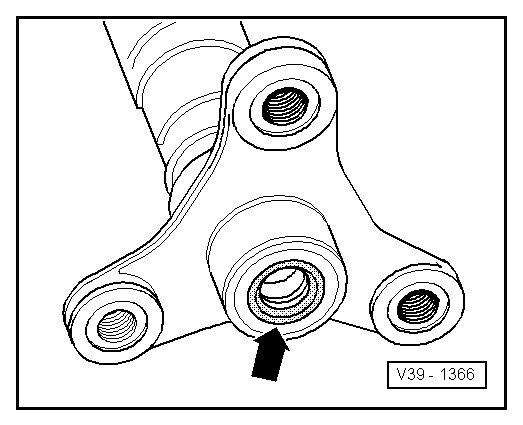

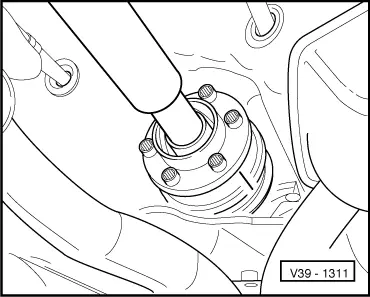

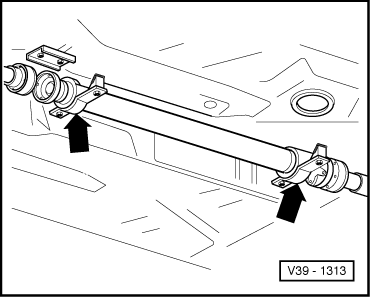

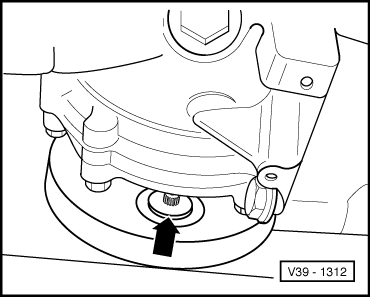

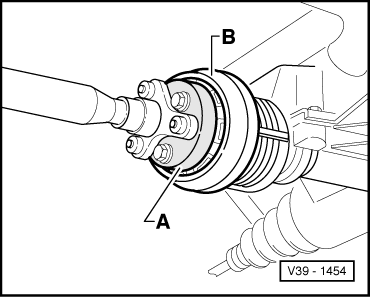

Note: Pull horizontally off centralizing pin, do not cant propshaft during removal from flexible coupling/heat shield. Centring sleeve seal must not be damaged ( ) otherwise the complete propshaft must be replaced. |

|

|

Notes:

Installing Installation of the three part propshaft is carried out in the reverse sequence. |